Hydraulic type tire vulcanizing machine with improved mold clamping structure

An improved tire vulcanization technology, which is applied in the field of hydraulic tire vulcanizers, can solve problems such as inconvenient space for maintenance, troublesome modification, and entry into the pit, and achieve the effect of overcoming the inconvenience of maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

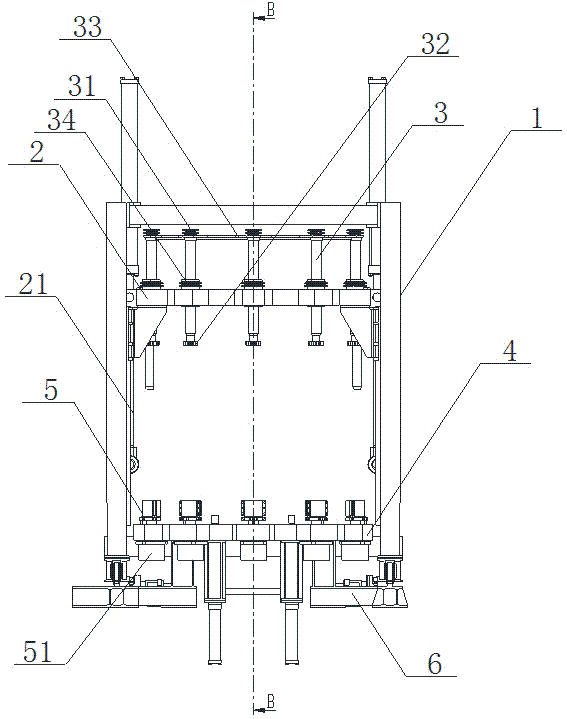

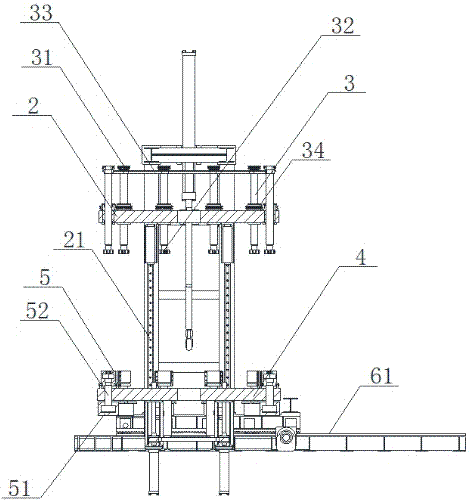

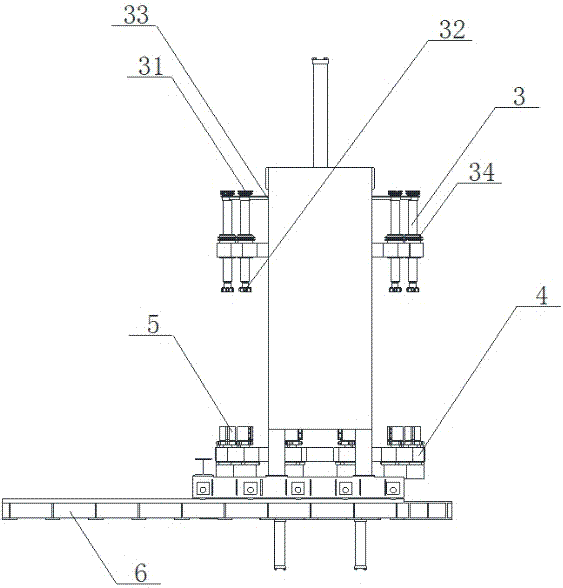

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] In the first embodiment of the hydraulic tire vulcanizing machine with improved clamping structure involved in the present invention, as Figure 1-5 As shown, it includes: a frame 1; an upper beam 2, which is arranged in the frame 1, and moves up and down in the frame 1 through a driving device 21. The driving device 21 can be driven by a motor and a pulley, except of course In addition, methods such as leading screws and guide rails known in the prior art can also be used. The upper beam 2 is also pierced with a plurality of tie rods 3 arranged equidistantly. The number of tie rods 3 should be adjusted according to the size of the tire. The number is not specifically limited here. The upper end of the pull rod 3 is provided with a first sprocket 31, and the transmission connection between the multiple first sprockets 31 is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com