A heavy-duty balance shaft assembly

A balance shaft, heavy load technology, applied in the direction of axle, elastic suspension, interconnection system, etc., can solve the problem of low reliability of the connection between the balance shaft assembly and the frame girder, the fracture of the bracket or the connecting bolt, and the aggravation of the wear of the single oil seal To achieve the effect of reducing maintenance service costs, reducing the risk of cracking failure, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

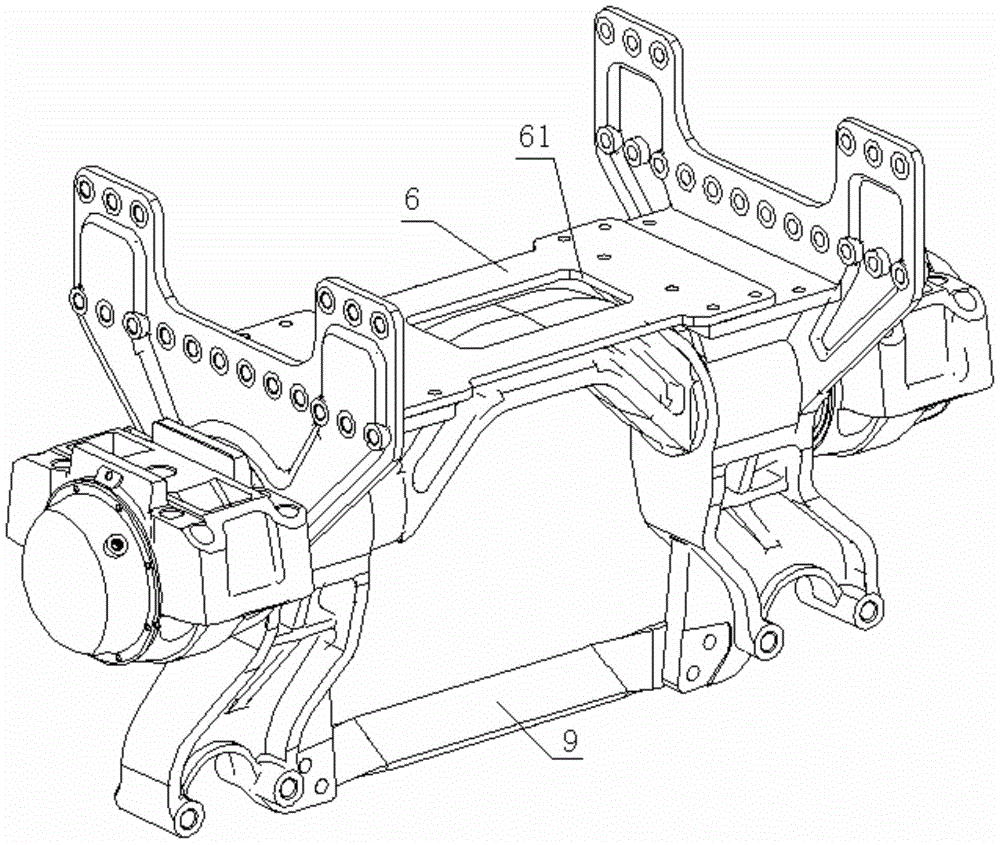

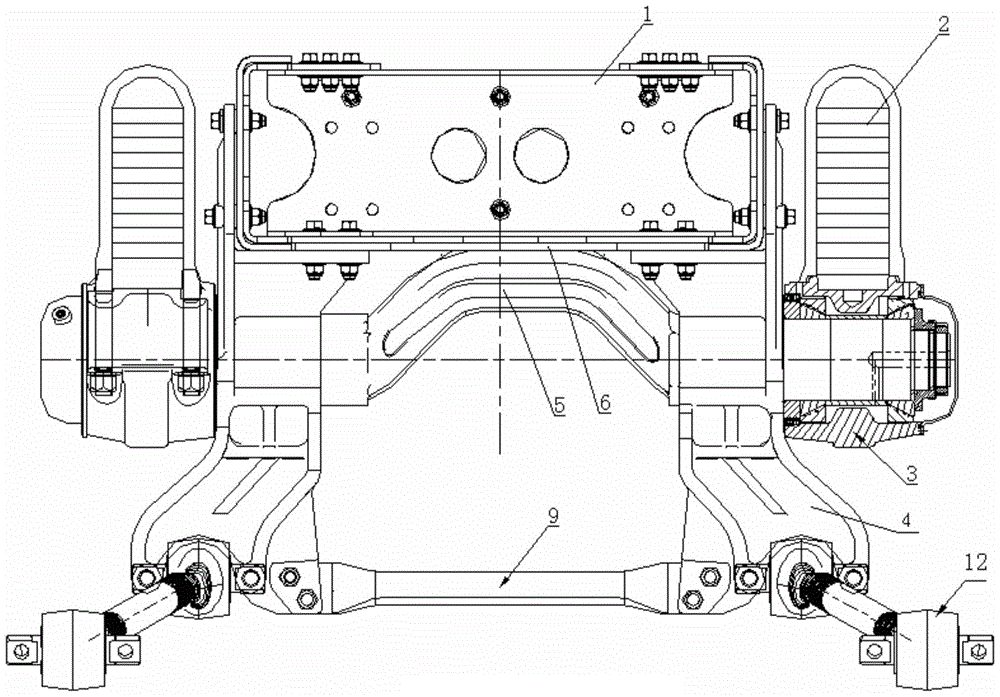

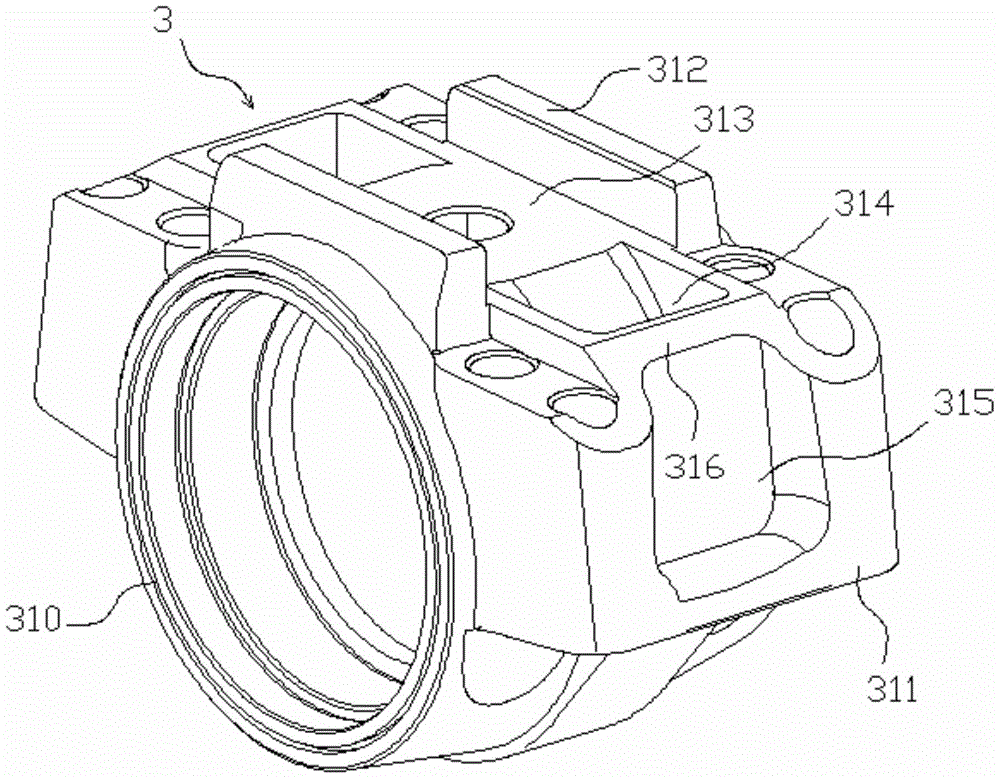

[0026] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. figure 1 and 2 As shown in a heavy-duty balance shaft assembly, the two sides of the shaft 5 are supported by the shaft bracket 4, the end of the shaft 5 is arranged in the shaft housing 3 through the bearing, and the end of the shaft housing 3 is provided with an end cover 411, and the shaft The top of the belt bracket 4 is L-shaped, and it has two mounting surfaces matched with the vehicle frame 1. The upper parts of the two shaft belt brackets 4 are connected by an upper connecting plate 6, and the middle part of the upper connecting plate 6 is provided with a square hole 61. The bottom of each shaft belt bracket 4 is connected by the lower connecting plate 9, the lower connecting plate 9 consists of a sloping plate portion 91 and straight plate portions 92 placed on both sides of the slopin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com