Electric Control System of Pneumatic Conveying Device

A technology of pneumatic conveying and electric control cabinet, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problem that the accuracy of the powder output by the powder feeder cannot be guaranteed, and the detection of powdery materials or powder concentration cannot cause sufficient problems. Pay attention to other issues to achieve a good delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

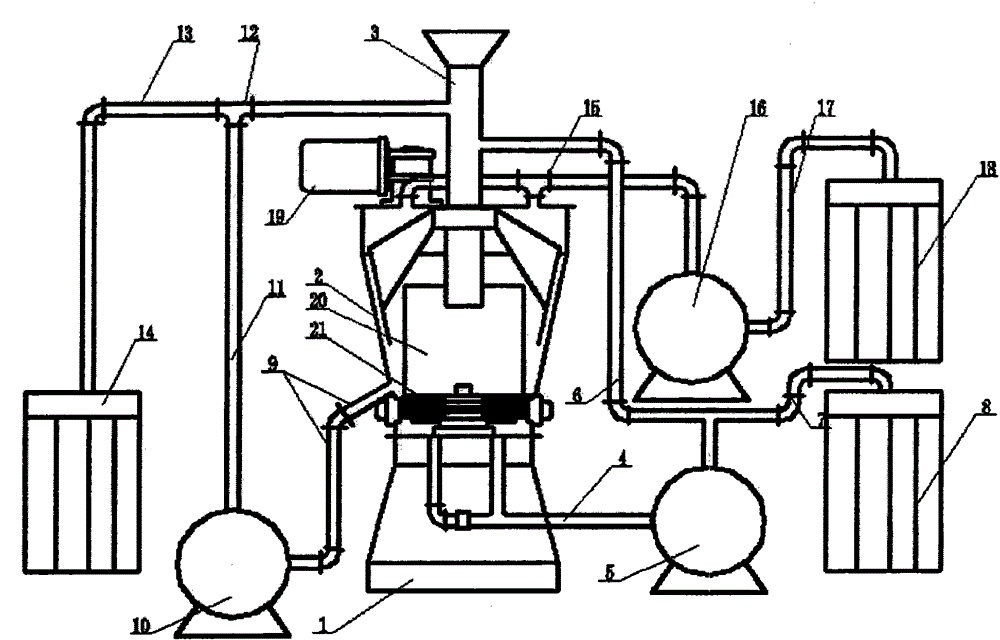

[0016] Embodiment 1: A pneumatic conveying device, including a base 1, a silo 2, a feed port 3, a discharge pipe 4, a No. 1 fan 5, a feed pipe 6, a collection pipe 7, and a collector 8. Discharge pipe 2 9, No. 2 fan 10, pipeline 11, feed pipe 2 12, collecting pipe 2 13, collector 2 14, discharge pipe 3 15, fan 3 16, collecting pipe 3 17. Collector 3 18. Scraper system 19. Filter screen 20. Cutter wheel 21. The silo 2 is installed on the base 1. The upper part of the silo 2 is provided with a feed port 3. The interior of the silo 2 is provided with Filter screen 20, cutter wheel 21 is installed on the bottom of feed bin 2, and cutter wheel 21 further crushes the unbroken bulk material, and filter screen 20 is made into a shell form, and filter screen 20 is arranged in the inside of feed bin 2 and is located Above the cutter wheel 20, the scraper system 19 is arranged on the outside of the feed bin 2, the shape of the scraper of the scraper system 19 matches the internal shape o...

Embodiment 2

[0017]Embodiment 2: A pneumatic conveying device, including a base 1, a silo 2, a feed port 3, a discharge pipe 4, a No. 1 fan 5, a feed pipe 6, a collection pipe 7, and a collector 8. Discharge pipe 2 9, No. 2 fan 10, pipeline 11, feed pipe 2 12, collecting pipe 2 13, collector 2 14, discharge pipe 3 15, fan 3 16, collecting pipe 3 17. Collector 3 18. Scraper system 19. Filter screen 20. Cutter wheel 21. The silo 2 is installed on the base 1. The upper part of the silo 2 is provided with a feed port 3. The interior of the silo 2 is provided with Filter screen 20, cutter wheel 21 is installed on the bottom of feed bin 2, and cutter wheel 21 further crushes the unbroken bulk material, and filter screen 20 is made into a shell form, and filter screen 20 is arranged in the inside of feed bin 2 and is located Above the cutter wheel 20, the scraper system 19 is arranged on the outside of the feed bin 2, the shape of the scraper of the scraper system 19 matches the internal shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com