Electric leveling supporting leg

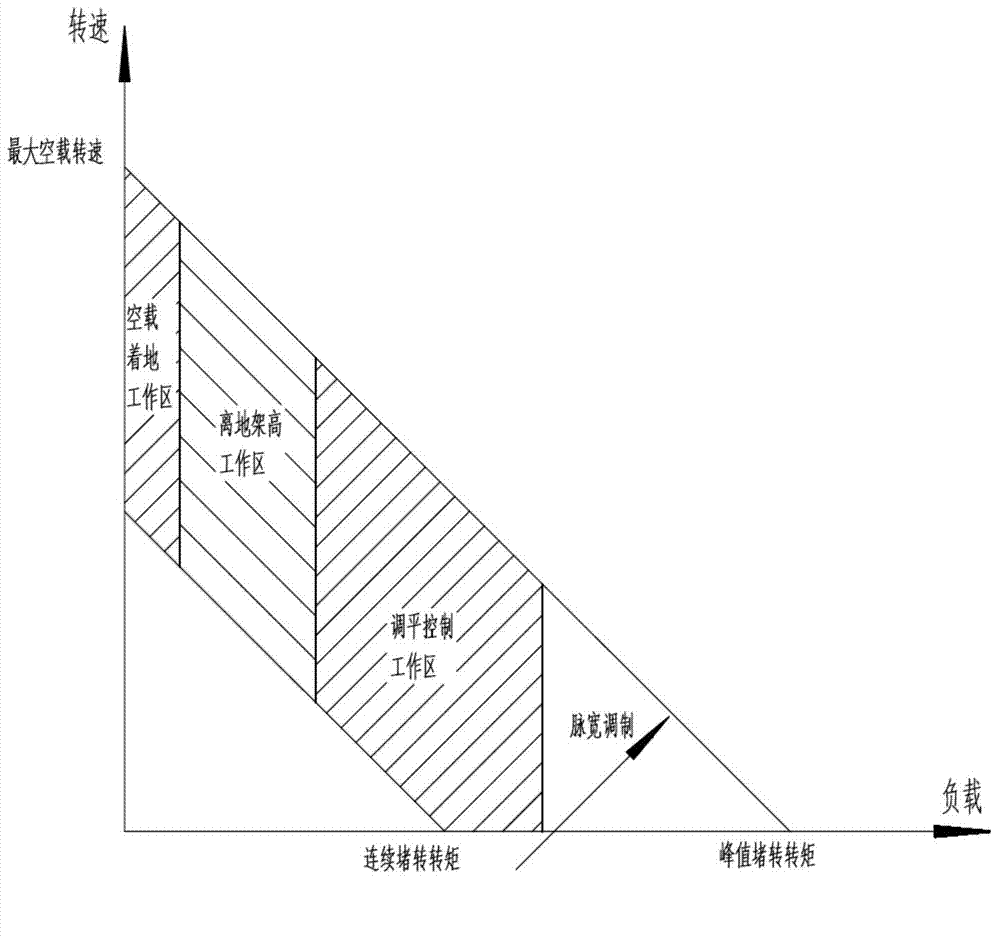

A support leg and electric technology, which is applied in the direction of supporting machines, engine frames, mechanical equipment, etc., can solve the problems that the electric support leg cannot be detected on the ground, manual operation is inconvenient, and the support leg does not have the locking function, etc., to improve Convenience, improvement of reliability and safety, effects of preventing misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

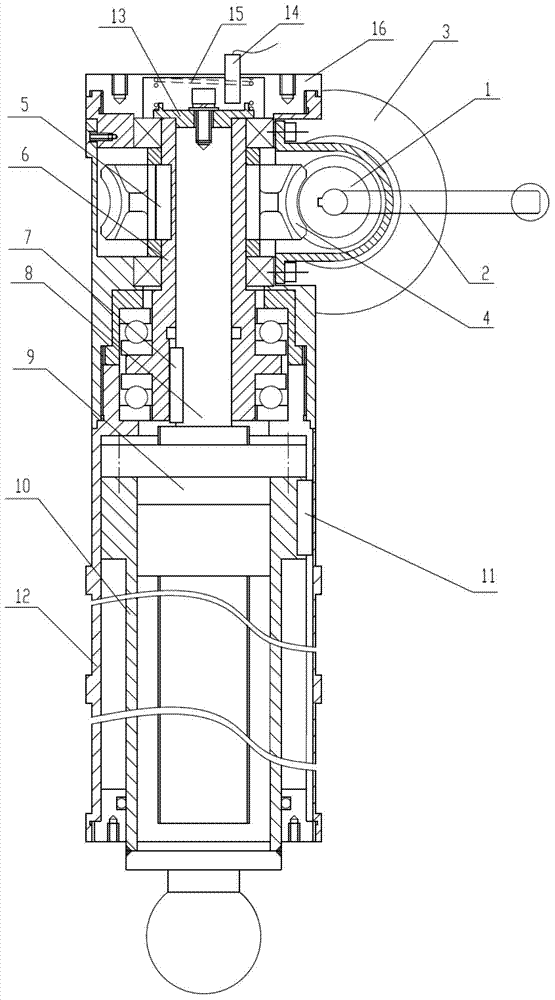

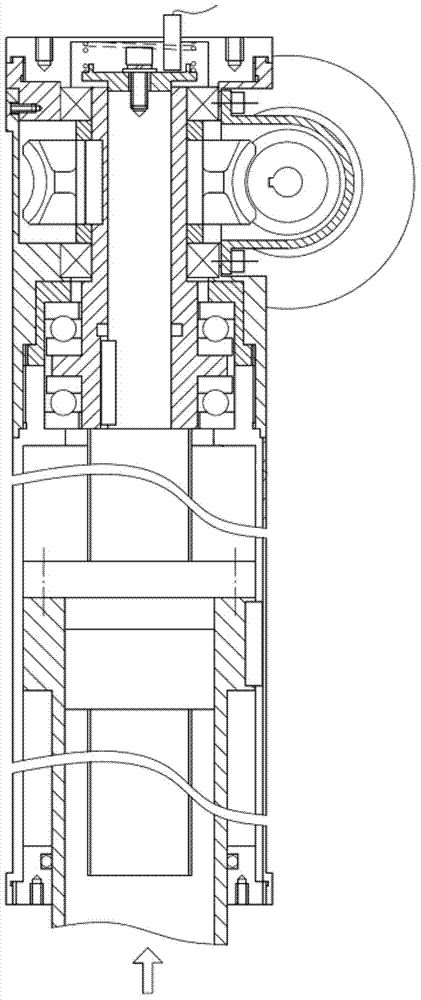

[0026] Such as figure 1 As shown, an electric leveling support leg mainly includes a worm screw 1, a crank handle 2, a torque motor 3, a turbine 4, a first flat key 5, a transition shaft 6, a second flat key 7, a screw rod 8, a nut 9, Guide rod 10, the third flat key 11, outer sleeve 12, gear cover 13, proximity switch 14, spring 15, top cover 16.

[0027] The action principle is as follows: the rotation of the torque motor 3 directly drives the rotation of the worm 1, and the worm 1 further drives the rotation of the worm wheel 4, drives the transition shaft 6 to rotate through the first flat key 5, and then drives the screw 8 to rotate through the second flat key 7, and further pushes the nut 9 and guide rod 10 stretch out or retract.

[0028] The proximity switch 14 is arranged on the top cover 16, and the retaining cover 13 is fixedly connected with the ball scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com