Control method for loading and load shedding of optimized module machine system

A control method and technology of a modular machine, which are applied in the directions of control input involving air characteristics, space heating and ventilation control input, heating mode, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] It should be clearly stated that this embodiment is not the only example. For those skilled in the art, without departing from the scope and essence of the present invention, various modifications can be made to the invention, such as modifying this In the invention, the value of each range interval or the number of each range interval, or extended application to other multi-compressors, chiller systems, etc. to realize the function of optimizing the loading and unloading of compressors, but these modifications also belong to the scope of protection of the present invention .

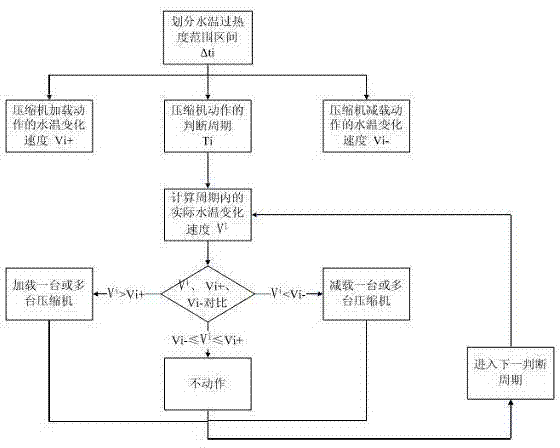

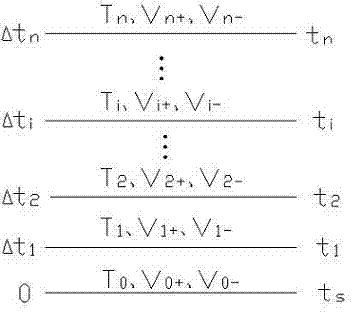

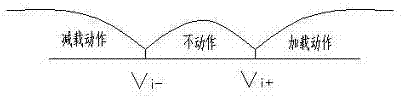

[0028] Such as figure 1 and 2 shown.

[0029] An optimized loading and unloading control method for a modular machine system, comprising the following steps:

[0030] Step 1. First divide the water temperature superheat Δt, that is, the difference between the actual water temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com