Wind control equipment for processing cooling of ultra-large wind power fan blade

A super large and super windy technology, applied in metal processing equipment, mechanical equipment, metal processing mechanical parts, etc., can solve the problems of shortening mold opening time, inconvenient use of fans, and inappropriate use of air conditioners, reducing continuous working time, controlling Convenience and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The working principle of the wind control equipment for processing and cooling super-large wind turbine blades of the present invention is as follows:

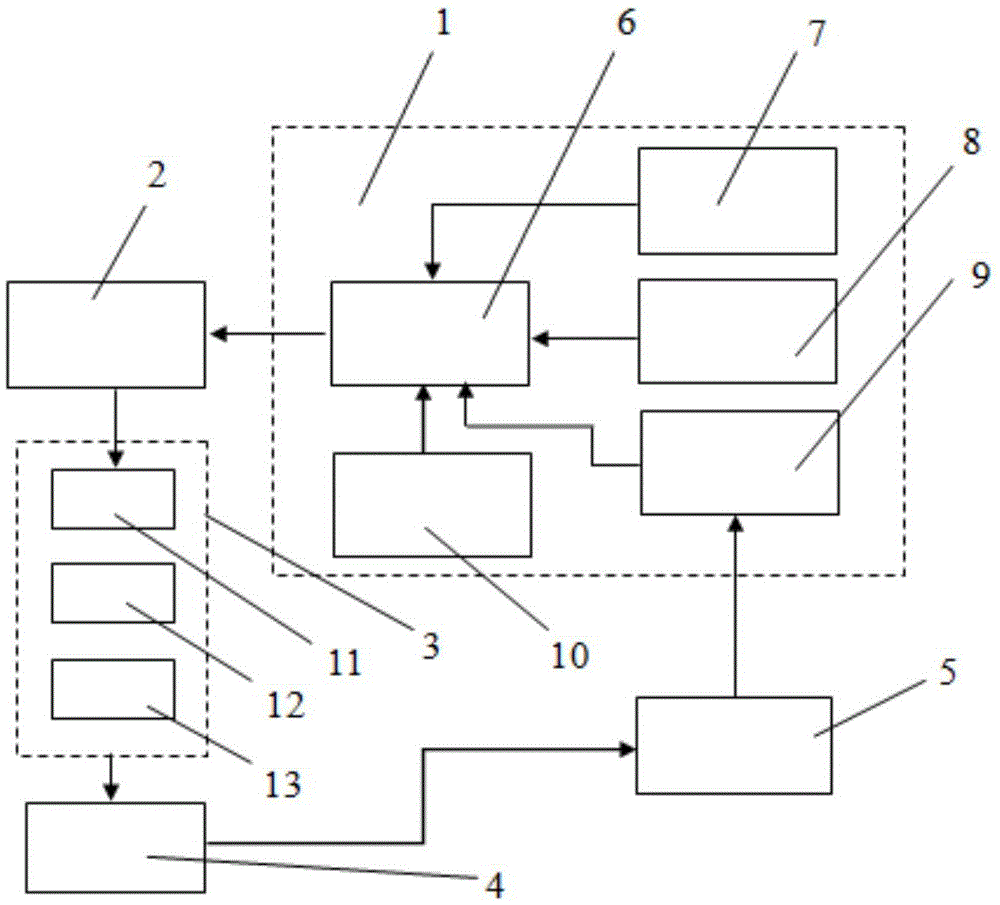

[0028] The wind control equipment for processing and cooling super large wind power fan blades of the present invention includes a frequency conversion control unit 1 , a combined fan 2 , an adjustable air duct 3 , super large wind power fan blades 4 , and a temperature measurement module 5 . The frequency conversion control unit 1 is connected with the combined fan 2 and connected with the temperature measuring module 5 . The adjustable air duct 3 is connected with the combined fan 2 . The frequency conversion control unit 1 adjusts the rotation speed and the size of the damper 12 in real time according to the detected temperature signal, so as to realize the required wind force and conveying distance. The 45-meter-long adjustable air duct 3 is made up of the flexible pipe 13 of metal air duct 11 with holes, regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com