Multi-cavity separated taking type vacuum drying box

A vacuum drying oven and multi-chamber technology, which is applied in the direction of drying solid materials, partial agitation dryers, dryers for static materials, etc., can solve the problems of affecting the drying effect of other materials and the large difference in drying temperature, and achieve the best drying effect Good, to avoid the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

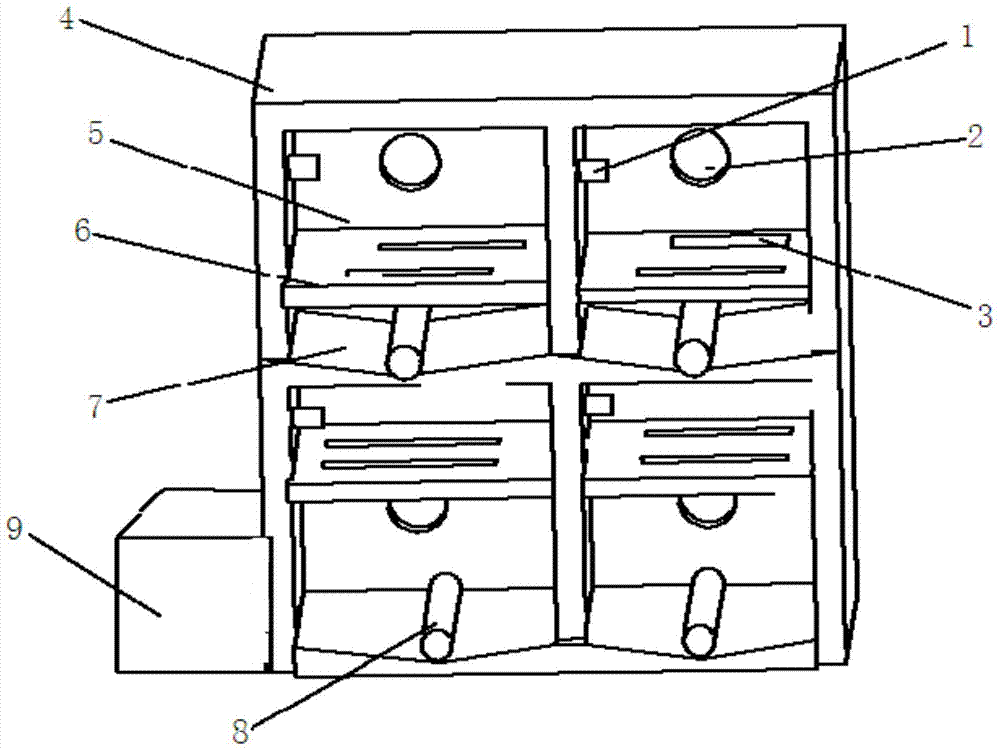

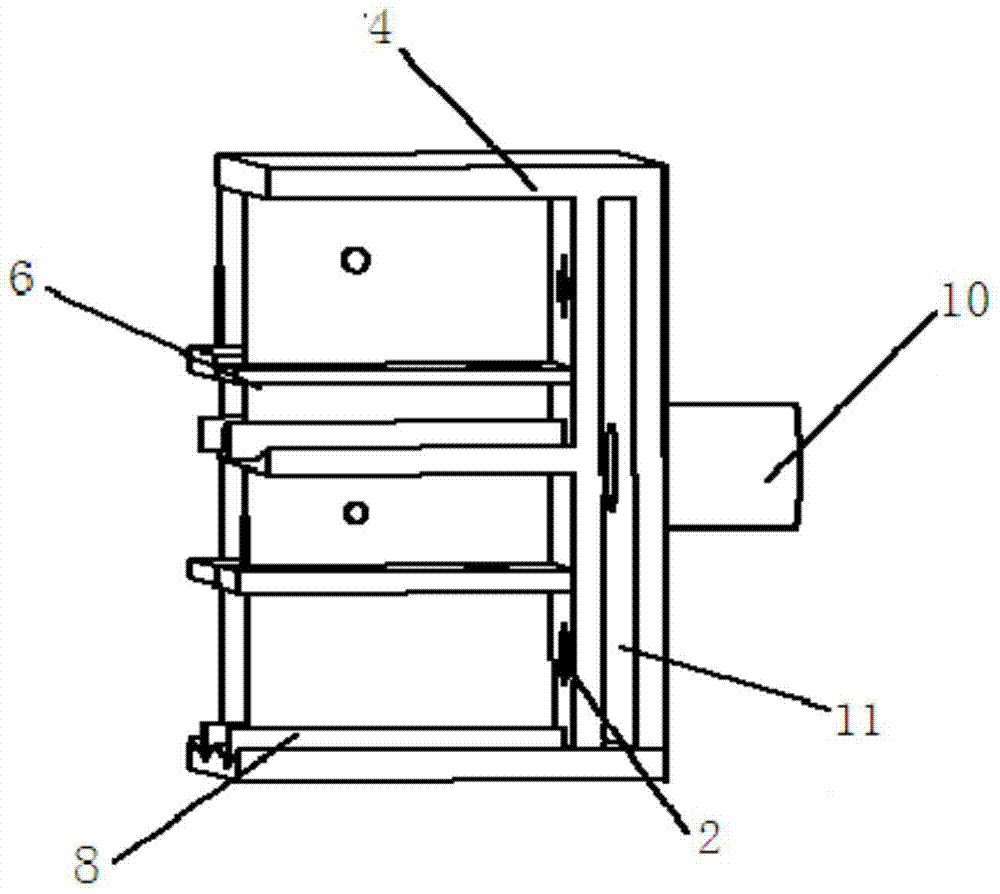

[0014] As shown in the figure, the present invention provides a multi-chamber split-type vacuum drying box, including a box body 4, an electric controller 9 and a vacuum pump (not shown in the figure), and the electric controller 9 and the vacuum pump are located outside the box body 4 , the internal space of the box body 4 is divided into a front material storage chamber and a rear vacuum chamber 11, and the rear vacuum chamber 11 is provided with an air release valve (not shown in the figure) and a vacuum connector 10 that can be connected to a vacuum pump;

[0015] The front material storage chamber is divided into four sub-chambers 5, and each sub-chamber 5 corresponds to a door (not shown in the figure). There is a switch control valve 2 on the rear side wall of the sub-chamber 5, and the sub-chamber 5 passes through The opening of the switch control valve 2 communicates with the rear vacuum chamber 11, and the sub-chamber 5 has a temperature and humidity sensor and a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com