Drop condensation enhanced heat exchange surface structure with draining hoses

A bead-like condensation and enhanced heat transfer technology, which is applied in the field of heat and mass transfer, can solve the problems of changing the surface properties of the heat transfer surface, unstable bead-like condensation state, and inability to apply to the industrial field, etc., and achieves simple and efficient beads. Congealed state, reducing the effect of covering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

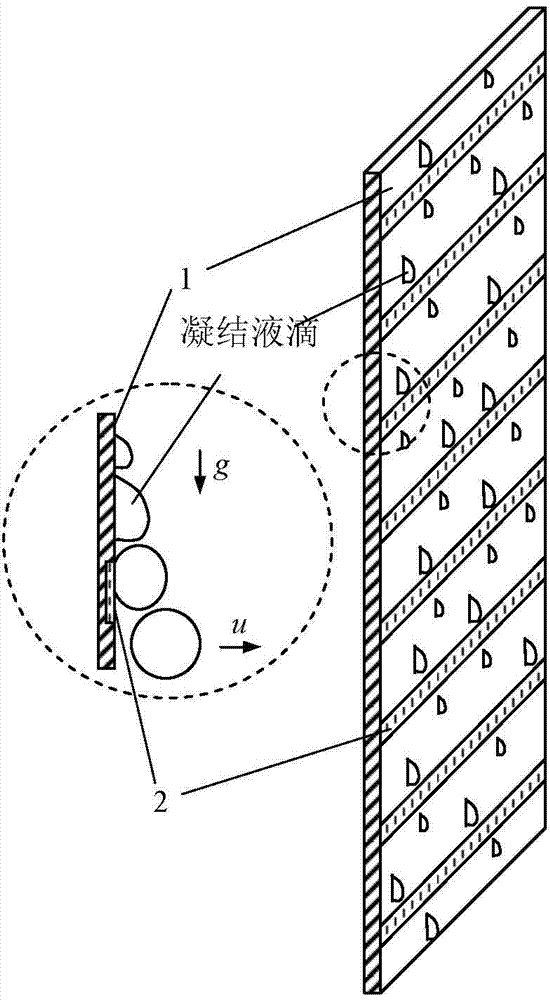

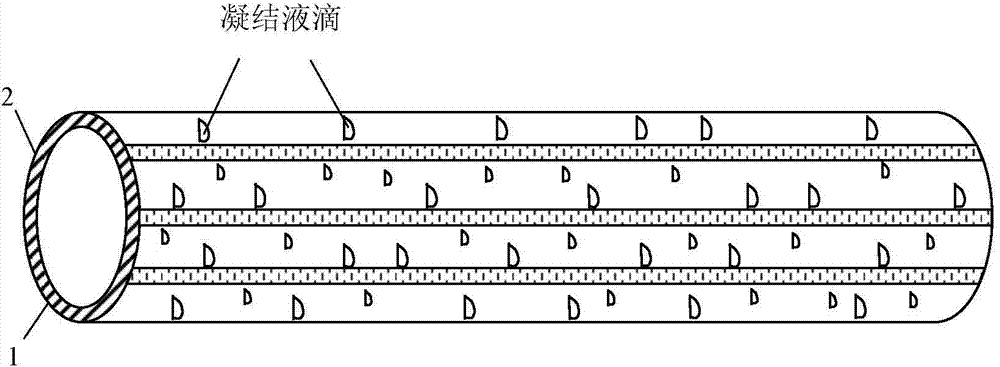

[0020] figure 1 It is a schematic diagram of a beaded condensation-enhanced heat exchange surface structure with a hydrophobic zone according to an embodiment of the present invention. The beaded condensation-enhanced heat exchange surface structure includes a heat exchange zone 1 and a hydrophobic zone 2, and a heat exchange zone 1 and a hydrophobic zone 2 Interval settings are used to maintain the bead-like condensation heat transfer process in which the condensed droplets fall off.

[0021] Wherein, the heat exchange zone 1 is a neutral wetting surface, and the contact angle is 80 to 100 degrees, preferably 90 degrees. The hydrophobic belt 2 is a hydrophobic surface with a width smaller than that of the heat exchange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com