A rapid construction method for concrete dams in severe cold areas to prevent cracks

A technology for concrete dams and construction methods, which is applied in the direction of dams, arch dams, gravity dams, etc., can solve the problems of affecting the effect of water flow and grouting of the dam body, difficult construction, cumbersome construction, etc. The effect of shorter coverage time and shorter exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

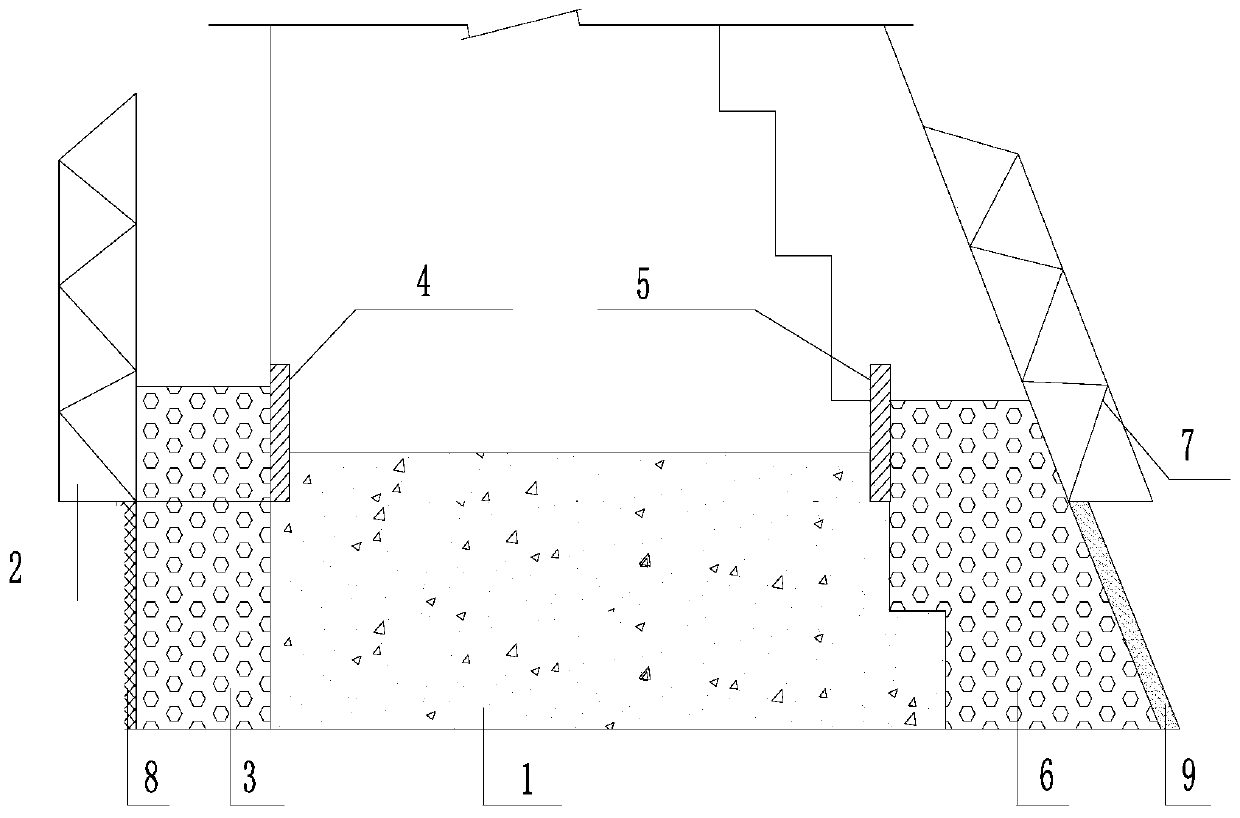

[0038] Such as figure 1 Shown, the concrete dam rapid construction method in severe cold area that prevents crack from producing of the present invention may further comprise the steps:

[0039] (1) In the layered construction of concrete dams, the upstream main formwork 2 and the downstream main formwork 7 are installed according to the design requirements, and the upstream side is installed at a certain distance from the upstream main formwork 2 and the downstream main formwork 7. Temporary formwork 4 and downstream side temporary formwork 5, upstream side foam concrete 3 is poured between upstream side main formwork 2 and upstream side temporary formwork 4, downstream side foam concrete is poured between downstream side main formwork 7 and downstream side temporary formwork 5 6;

[0040] (2) After the upstream foam concrete 3 and the downst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com