Sidelight backlight module and LGP (Light Guide Plate) thereof

A backlight module and side-light technology, which is applied in the field of side-light backlight modules and light guide plates, can solve problems such as light leakage, reduced LED heat dissipation performance, and poor brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An edge-lit backlight module provided by the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

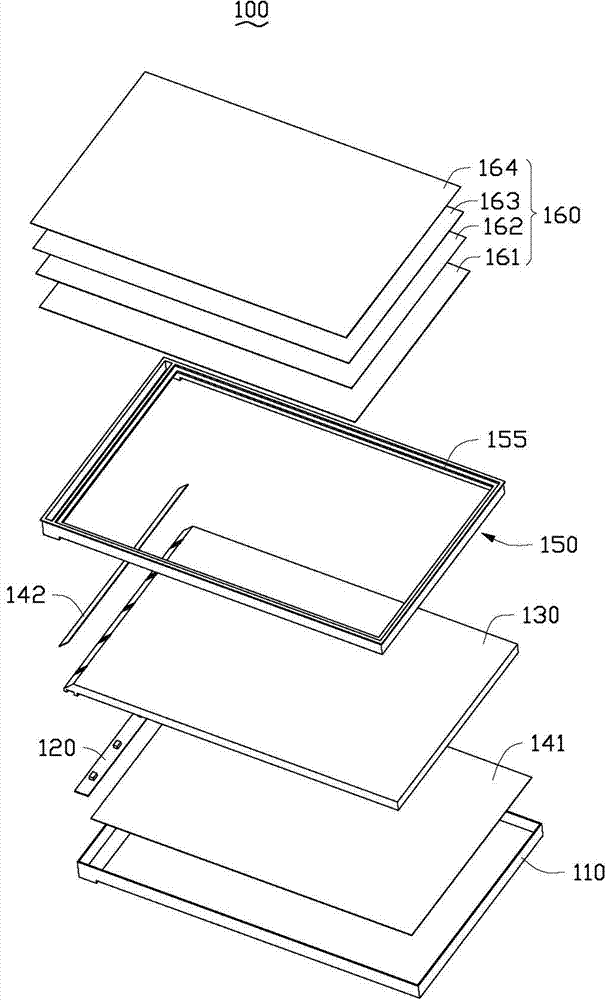

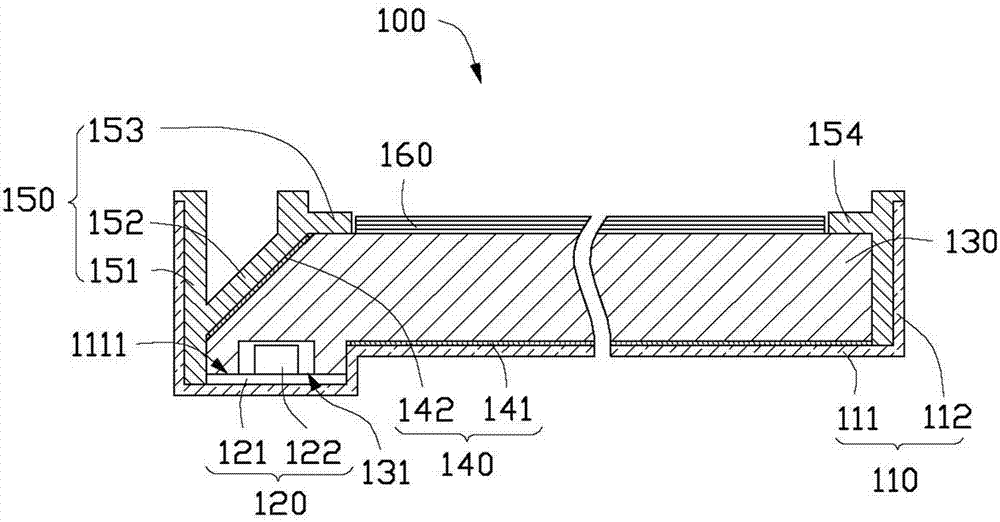

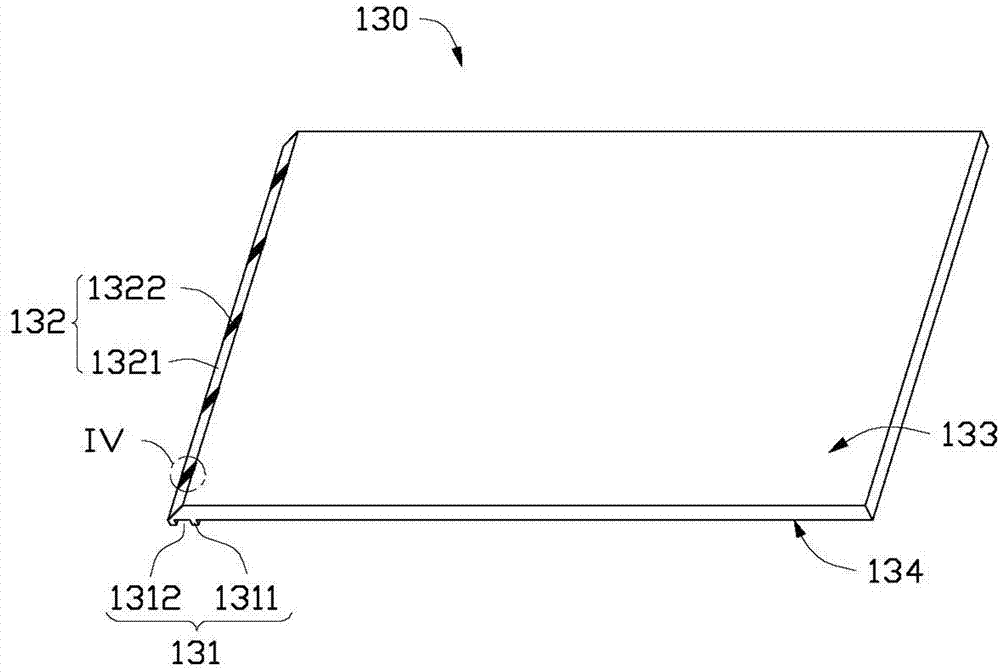

[0018] Please also see figure 1 and figure 2 Embodiment 1 of the present invention provides an edge-lit backlight module 100, including a back cover 110, an LED light source 120, a light guide plate 130 accommodated in the back cover 110, a reflective sheet 140, and a plastic frame set on the light guide plate 130 150 and optical sheet group 160.

[0019] The back cover 110 is made of metal sheet material, and includes a bottom plate 111 and a plurality of sidewalls 112 vertically extending from the edge of the bottom plate 111 to one side thereof. The bottom plate 111 is recessed with a groove 1111 adjacent to and parallel to the side wall 112 .

[0020] The LED light source 120 is strip-shaped and includes a substrate 121 and a plurality of LEDs 122 disposed on the substrate 121 . The LED light sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com