Terminal Connection Structure

A terminal and structure technology, applied in the direction of connection, conductive connection, structural connection, etc., to achieve the effect of easy connection operation, increased volume, and a wide range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

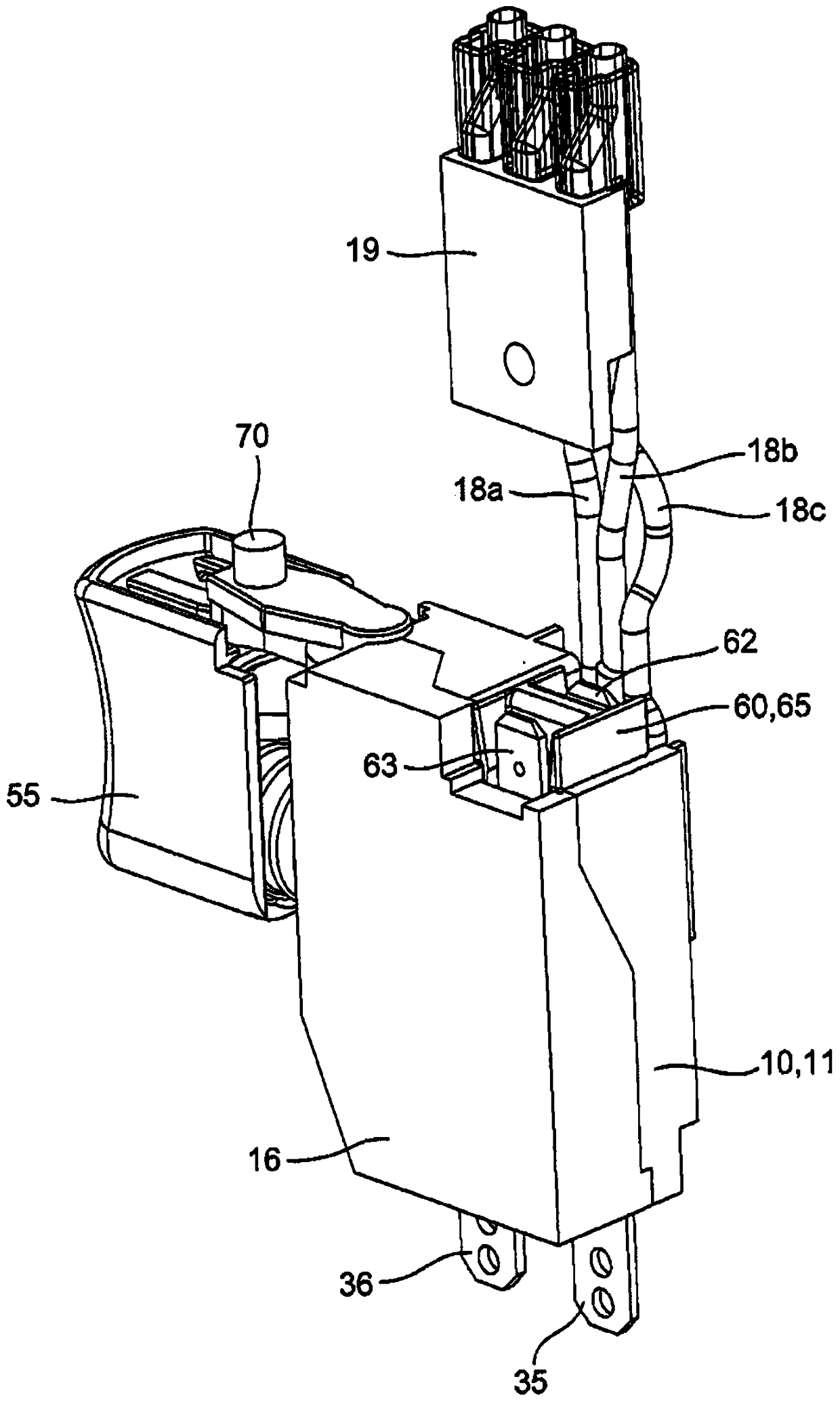

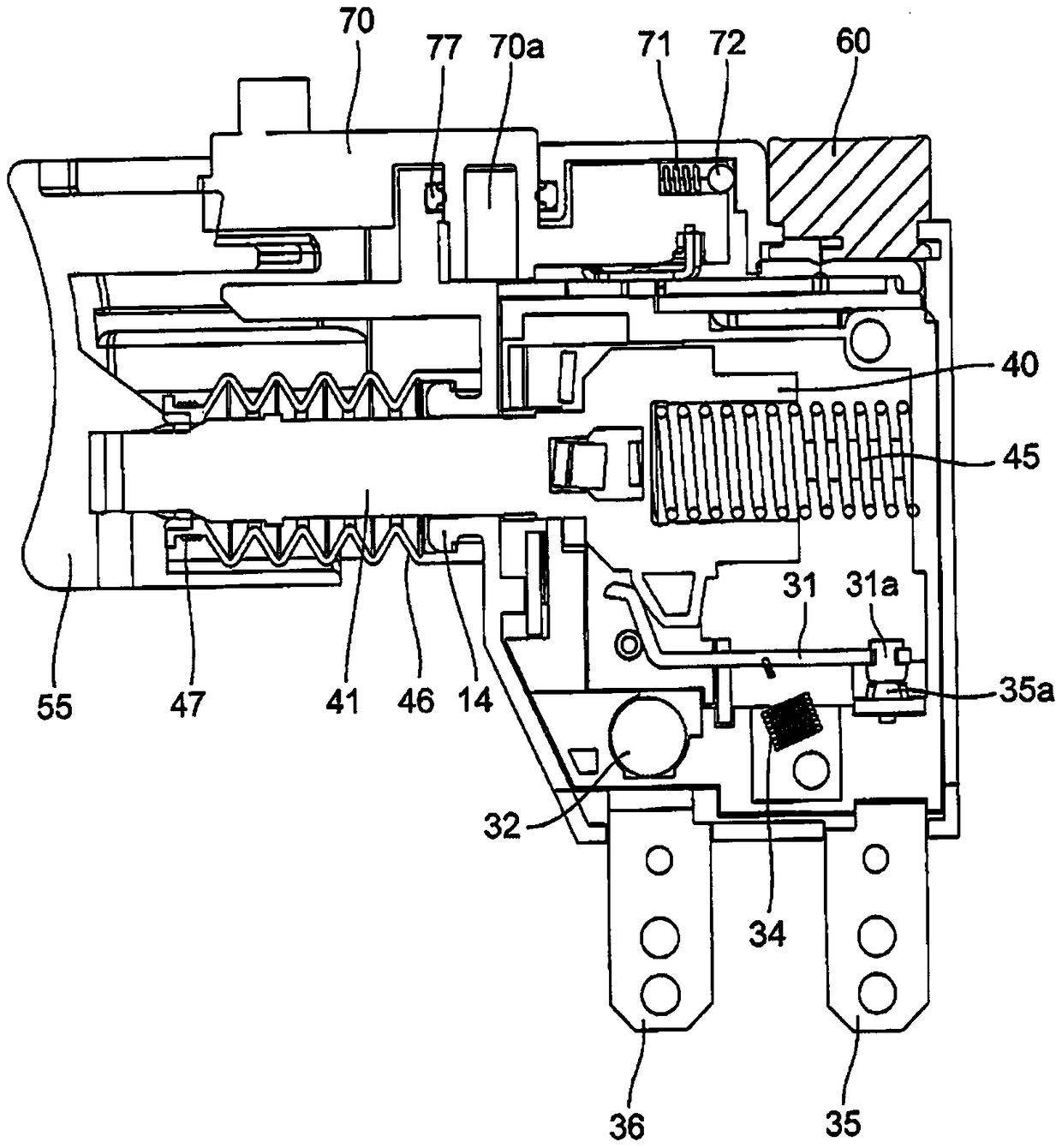

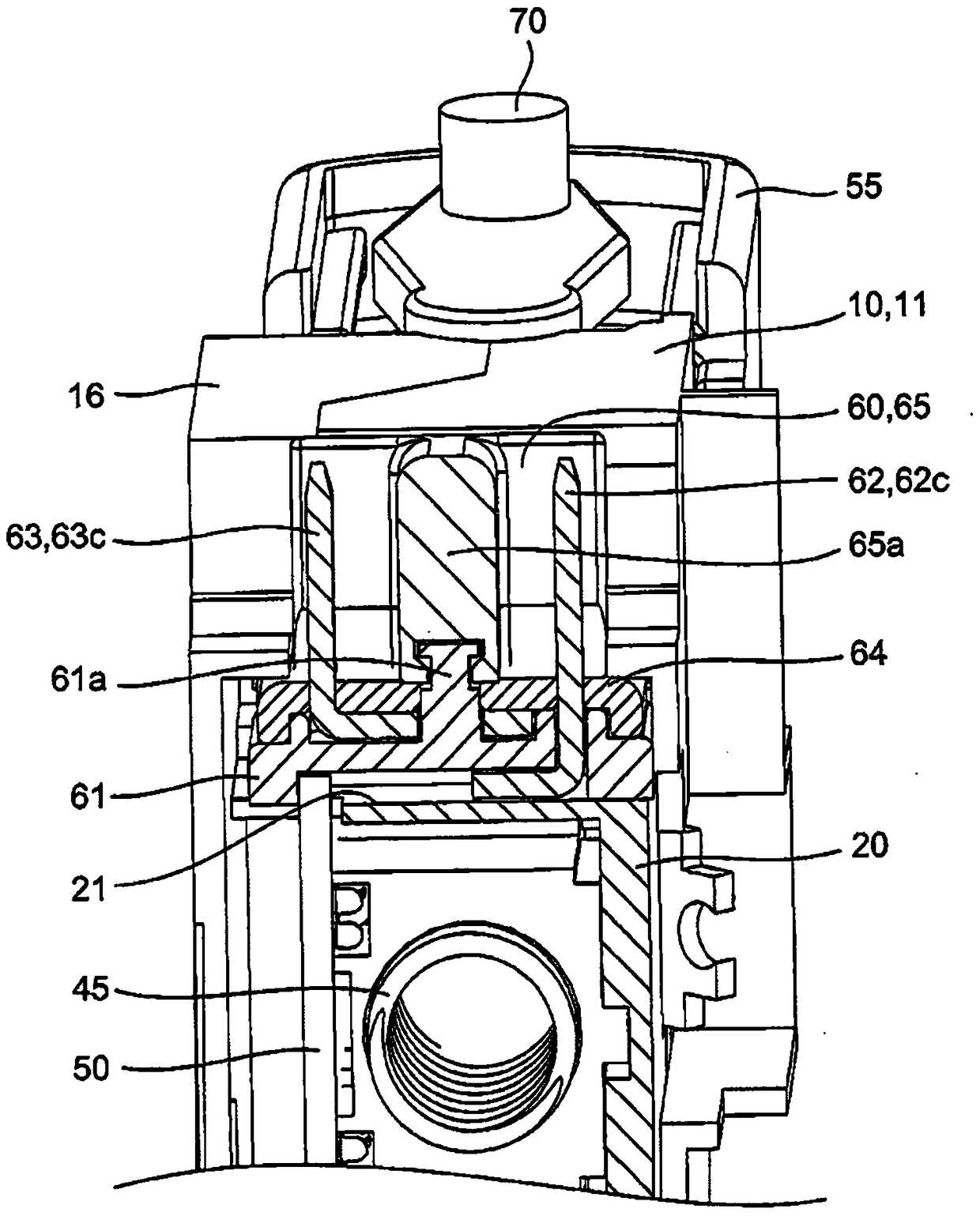

[0106] according to Figure 1 to Figure 26 The accompanying drawings illustrate the connection structure of the terminal of the present invention.

[0107] Such as Figure 1 to Figure 10 As shown, the terminal connection structure of the first embodiment is applicable to the case of a trigger switch for an electric tool, in particular, the case of unitizing the joint terminal for a motor protruding upward.

[0108] That is, if Figure 4 and Figure 5 As shown, the above-mentioned trigger switch is assembled in the housing 10 formed by combining the first cover 11 and the second cover 16, and the internal components such as the base body 20, the plunger 40, and the printed circuit board 50 are assembled, and the trigger 55 and the terminal unit are assembled. 60 and operating rod 70. In addition, a socket 19 is connected to internal components such as the printed circuit board 50 through lead wires 18a, 18b, and 18c.

[0109] Such as Figure 4 As shown, the first cover 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com