Semiconductor laser made by zinc oxide quantum well hybrid and its manufacturing method

A technology of quantum well hybridization and manufacturing method, which is applied in the field of laser manufacturing to achieve the effect of improving the optical confinement factor, good compatibility, and simple and easy manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

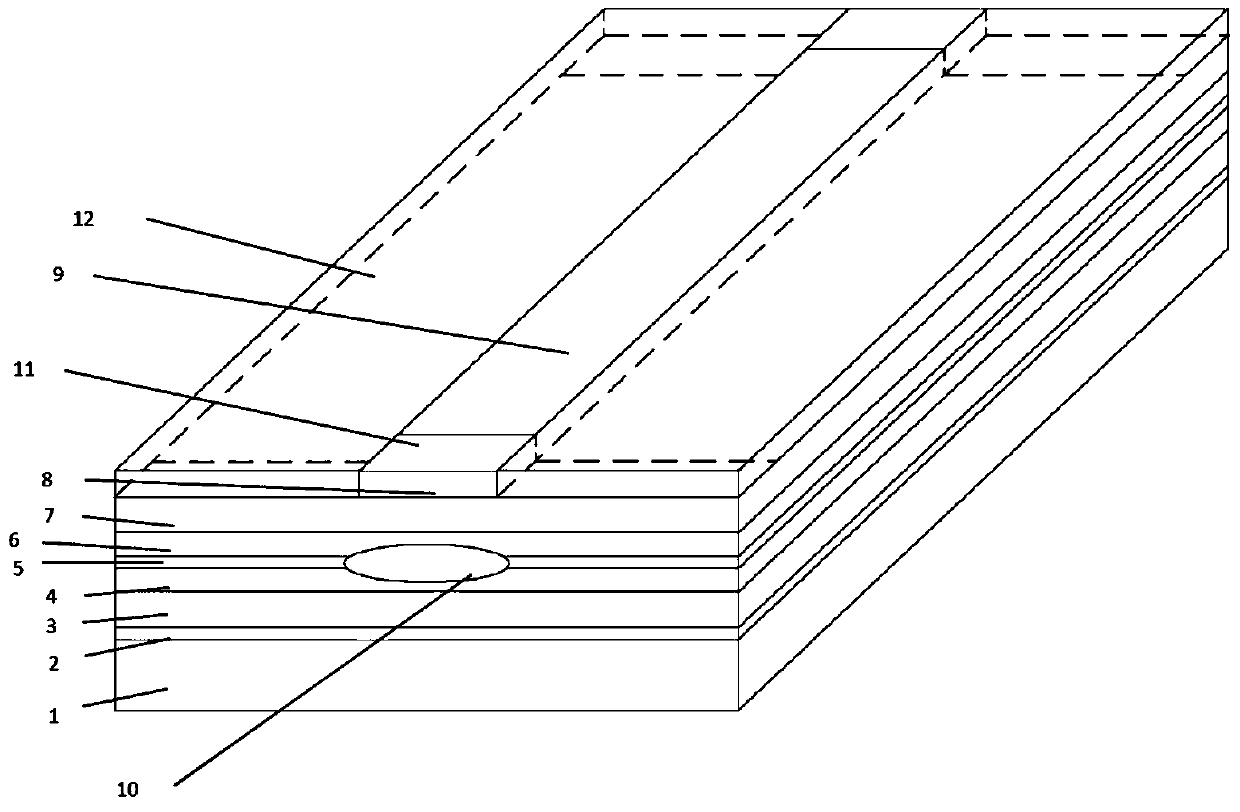

[0044] Embodiment 1 is the 808nm strip structure high-power semiconductor laser that utilizes zinc oxide quantum well hybridization to make, and its structure is as follows figure 1 As shown, including the epitaxial wafer, the specific structure of the epitaxial wafer is arranged in order from bottom to top: substrate 1, buffer layer 2, lower confinement layer 3, lower waveguide layer 4, quantum well and quantum barrier region 5, upper waveguide layer 6 , the upper confinement layer 7 and the upper ohmic contact layer 8 . The longitudinal centerline of the upper ohmic contact layer 8 is provided with a strip-shaped light-emitting area 9, and the strip-shaped light-emitting area 9 is surrounded by a zinc oxide film layer grown after the upper ohmic contact layer 8 is corroded. The thickness of the zinc oxide film layer is the same as that of the upper ohmic contact layer. The thicknesses of the layers 8 are equal, and the zinc oxide film layer is divided into a zinc oxide film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com