Unpowered articulated arm type demonstrator and application thereof in industrial robot

A technology of industrial robots and articulated arms, which can be used in educational appliances, instruments, claw arms, etc., can solve the problems of high cost, large error, and slow robot teaching speed, and achieve low cost, fast teaching speed, and improved range of motion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

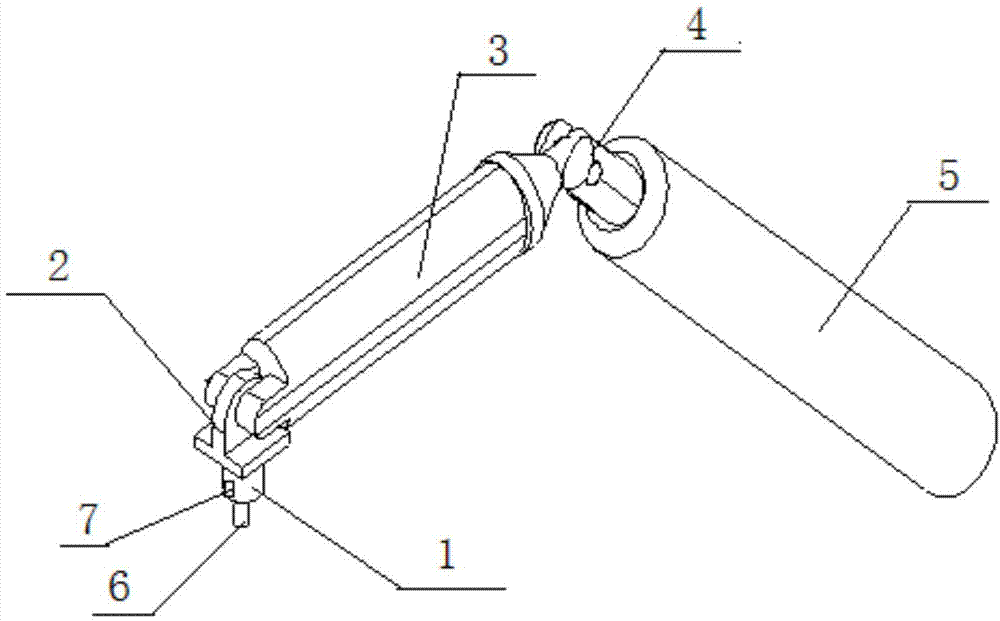

[0045] A kind of unpowered articulated arm type teaching pendant of this embodiment comprises unpowered articulated arm structure, Mocap equipment and auxiliary computer, such as figure 2 As shown, the structure of the unpowered articulated arm includes an articulated arm A1, a joint A2, an articulated arm B3, a joint B4, an articulated arm C5, a probe 6 and a recording button 7, wherein: the articulated arm A1 and the articulated arm B3, the joint The arm B3 and the articulated arm C5 are connected sequentially through joints A2 and B4; the probe 6 is detachably connected to the end of the articulated arm A1, and the recording button 7 is fixedly connected to the side of the articulated arm A1; the Mocap device is set On the articulated arm A1, the articulated arm B3 and the articulated arm C5; the auxiliary computer is connected to the Mocap device through wireless communication, which is convenient for collecting and capturing motion data at any time.

[0046] The applicat...

Embodiment 2

[0054] The basic structure of the non-powered articulated arm teaching pendant of this embodiment is the same as that of Embodiment 1, the difference is that the joints A2 and B4 are universal joints, so that the measuring head can reach any direction within the length range of the articulated arm. The position is convenient for the collection of position data; and the rotation angle sensors perpendicular to each other are provided; the articulated arm A1 and the articulated arm B3 are telescopic rod-shaped structures with variable length, which can improve the range of motion of the articulated arm and improve the versatility of the device ; And a displacement sensor is provided. The use of the rotation angle sensor and the displacement sensor can improve the cross confirmation of the collection point of the joint arm and improve the accuracy of the data collection point;

[0055] The application of a non-powered articulated arm teaching pendant in an industrial robot in this...

Embodiment 3

[0062] An unpowered articulated arm teaching pendant in this embodiment has the same structure as that in Embodiment 2.

[0063] The application of a non-powered articulated arm teaching pendant in an industrial robot in this embodiment includes the following steps:

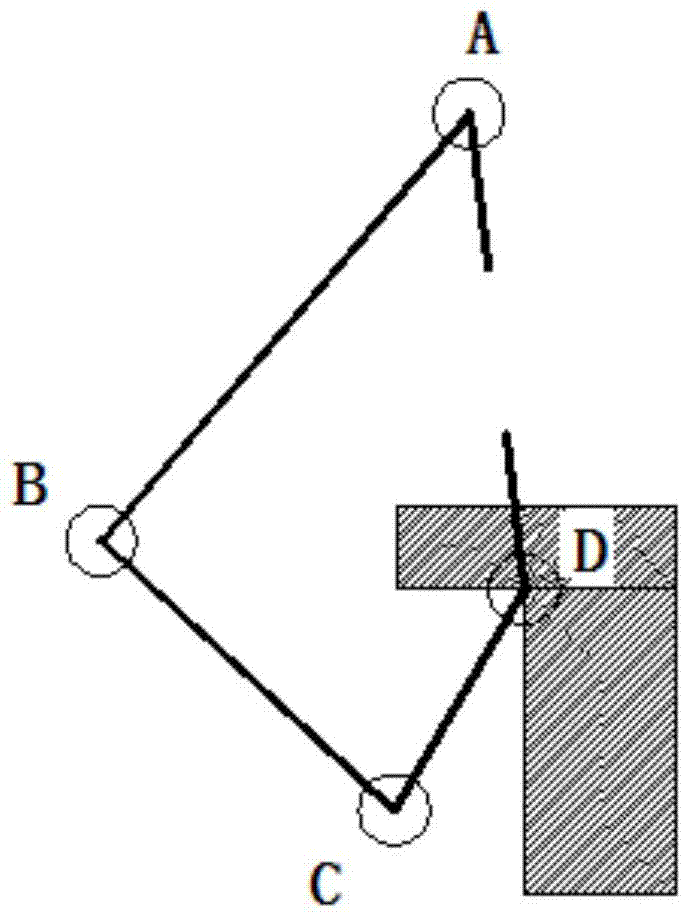

[0064] A. Positioning confirmation: The operator moves and locates the teaching point of the point-to-point movement, linear movement, and arc movement that need to be recorded by swinging the unpowered articulated arm structure through the probe 6. The probe 6 can move around the X and X of the joint A2. Z-axis rotation, articulated arm B3 can rotate around the Y-axis of joint B4, or let articulated arm B3 and articulated arm C5 rotate around the X-axis through joint B4, and the joint arm C5 and the industrial robot can rotate around the Z-axis through rotation. Swing up and down around the X axis, press the record button 7; combined with a three-coordinate measurement system, improve the accuracy of the teachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com