Teaching robot and operating method thereof

A technology for teaching robots and robots, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high equipment cost, complex operation, and difficulty in getting started, and achieve stable and reliable operation, simple mechanical structure, and not easy to misuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

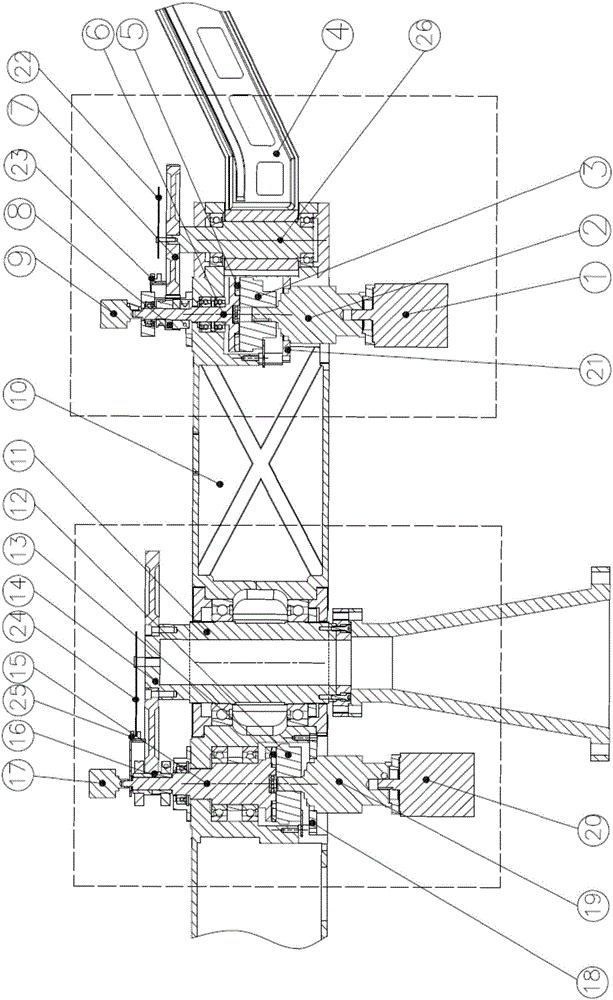

[0032] The invention belongs to the field of robot automation, and relates to a fast robot teaching method and a corresponding robot body transmission structure. The mechanical structure includes a driving motor, a reducer, an electromagnetic clutch, meshing gears, a shaft, a sensor, and an arm. The driving motor is connected to the reducer to obtain a large torque. The output shaft of the reducer is connected to the electromagnetic clutch to form a power stage. The other end of the clutch passes through The gear meshes with the arm body to drive the arm body to rotate to form the load end. When the trajectory of the robot is reproduced and running, the clutch is in the state of engagement, and the rotational power of the motor is transmitted to each arm to achieve the purpose of driving the arm. The clutch can be disconnected when the robot is teaching, so that the robot joints are in a free state without power. Directly move the arm of the robot by hand to move along the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com