Channel dividing conveying device for conical flask

A technology for conveying equipment and conical flasks, which can be used in conveyors, conveyor objects, packaging, etc., and can solve problems such as easy dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

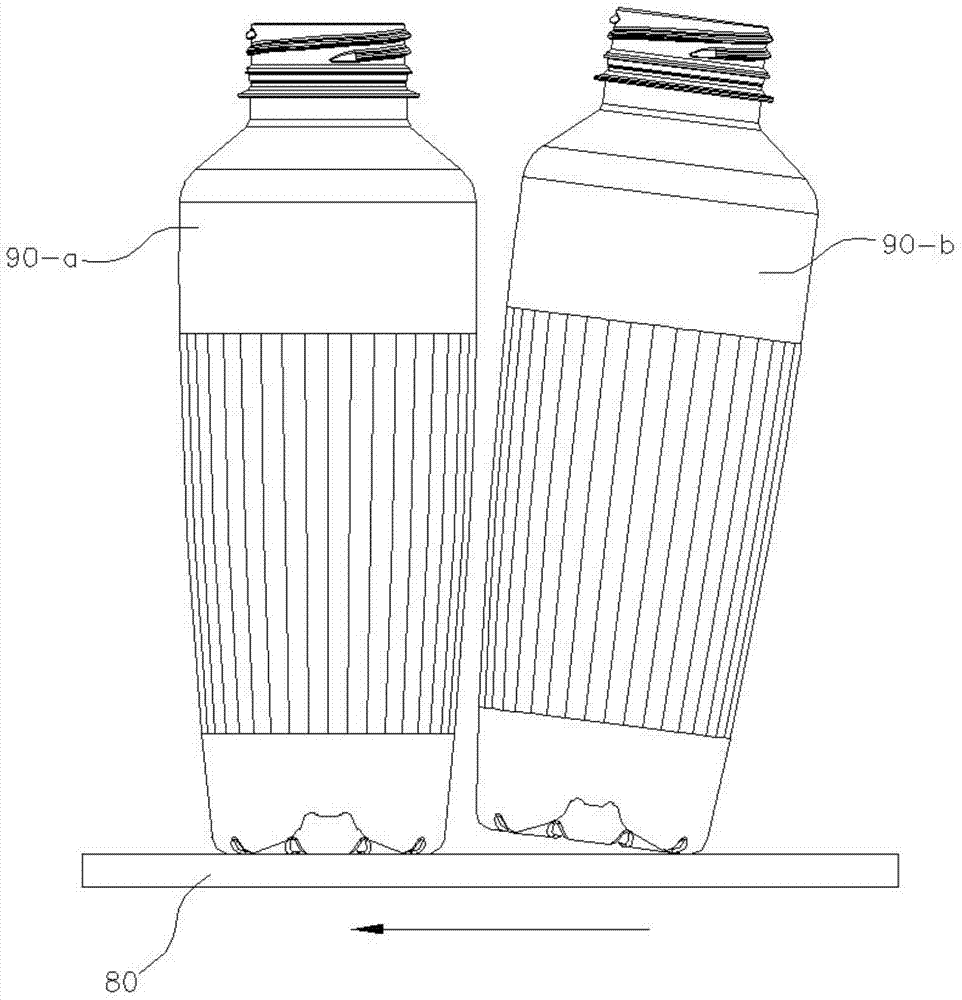

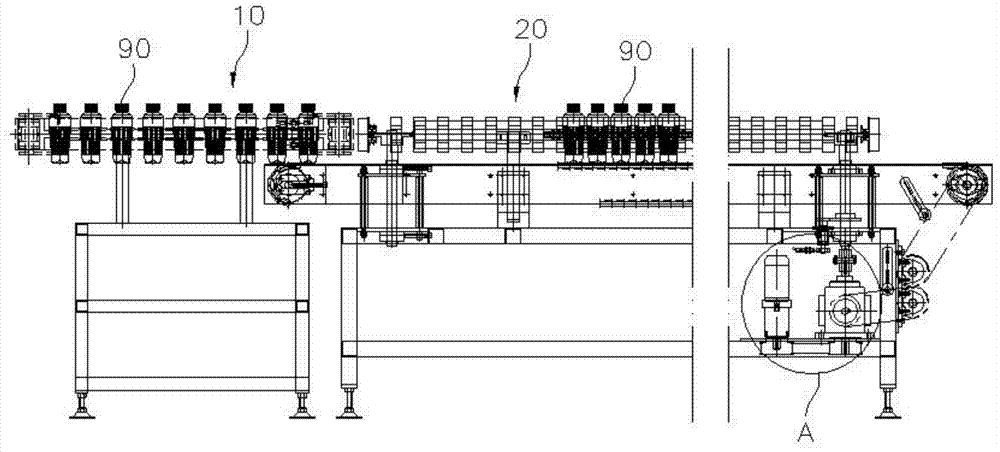

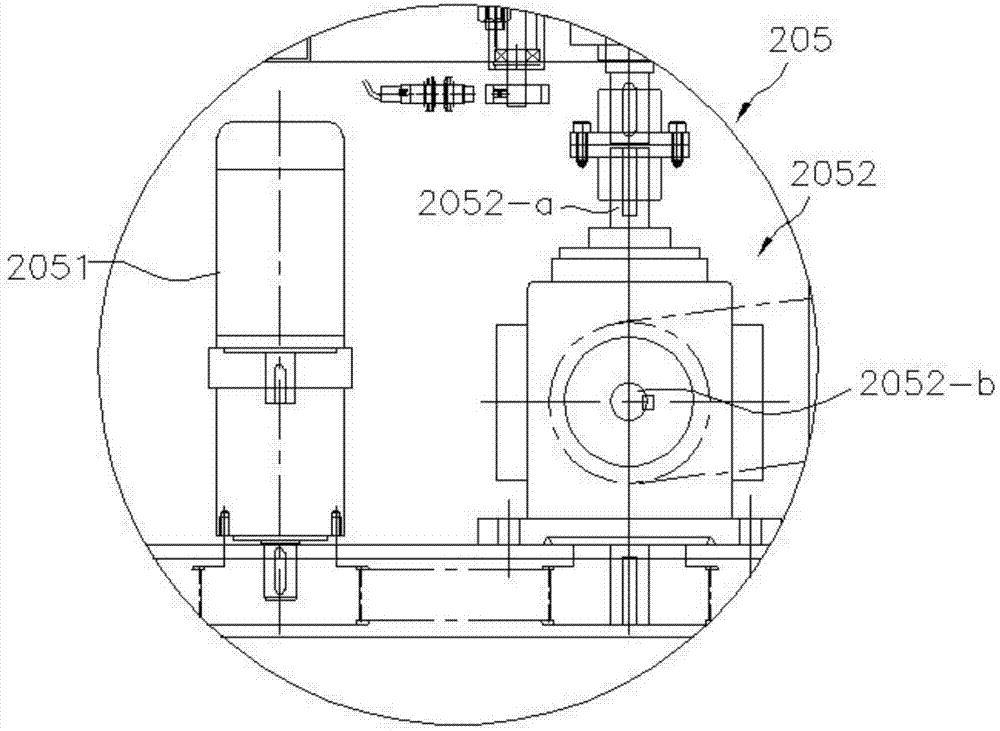

[0037] combine figure 2 , Figure 4 , Figure 5 , an Erlenmeyer flask lane-separating conveying equipment, comprising a linear conveying device 10, a lane-dividing conveying mechanism 20, and a lane-dividing device 30.

[0038] combine Image 6 , Figure 7 , the linear conveying device 10 includes a linear conveying unit 11, a horizontal conveying base plate 12, the linear conveying unit 11 includes a conveyor belt 111, a pair of rollers 112 for driving the conveyor belt, and a motor 113 for driving the rollers 112 to rotate, The pair of rollers 112 are vertically pivoted on the horizontal conveying bottom plate 12, the number of the linear conveying units 11 is two, and the two linear conveying units 11 are arranged side by side on the horizontal conveying bottom plate 12, the two The gap between the linear conveying units 11 is equal to the maximum outer diameter of the Erlenmeyer flask 90 .

[0039] Such as Figure 4 As shown, the lane-dividing conveying mechanism 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com