An organic-based ceramic slurry suitable for tape casting

A technology of ceramic slurry and casting process, applied in the field of ceramic slurry, can solve the problems of lack of fluidity and sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0107] The contriver surprisingly finds that the mixed dispersant (castor oil, glycerol, and trioleic acid glyceride, its mass ratio is (1~1.2):(0.9~1.1):1) of the specific amount combination of the present invention, specific The combination of mixed solvent (10-16 parts by weight of ethanol, 8-12 parts by weight of butanone;) and specific plasticizer (dibutyl phthalate) can be combined with other components to obtain fluidity and An organic-based ceramic slurry suitable for tape casting with excellent sinterability.

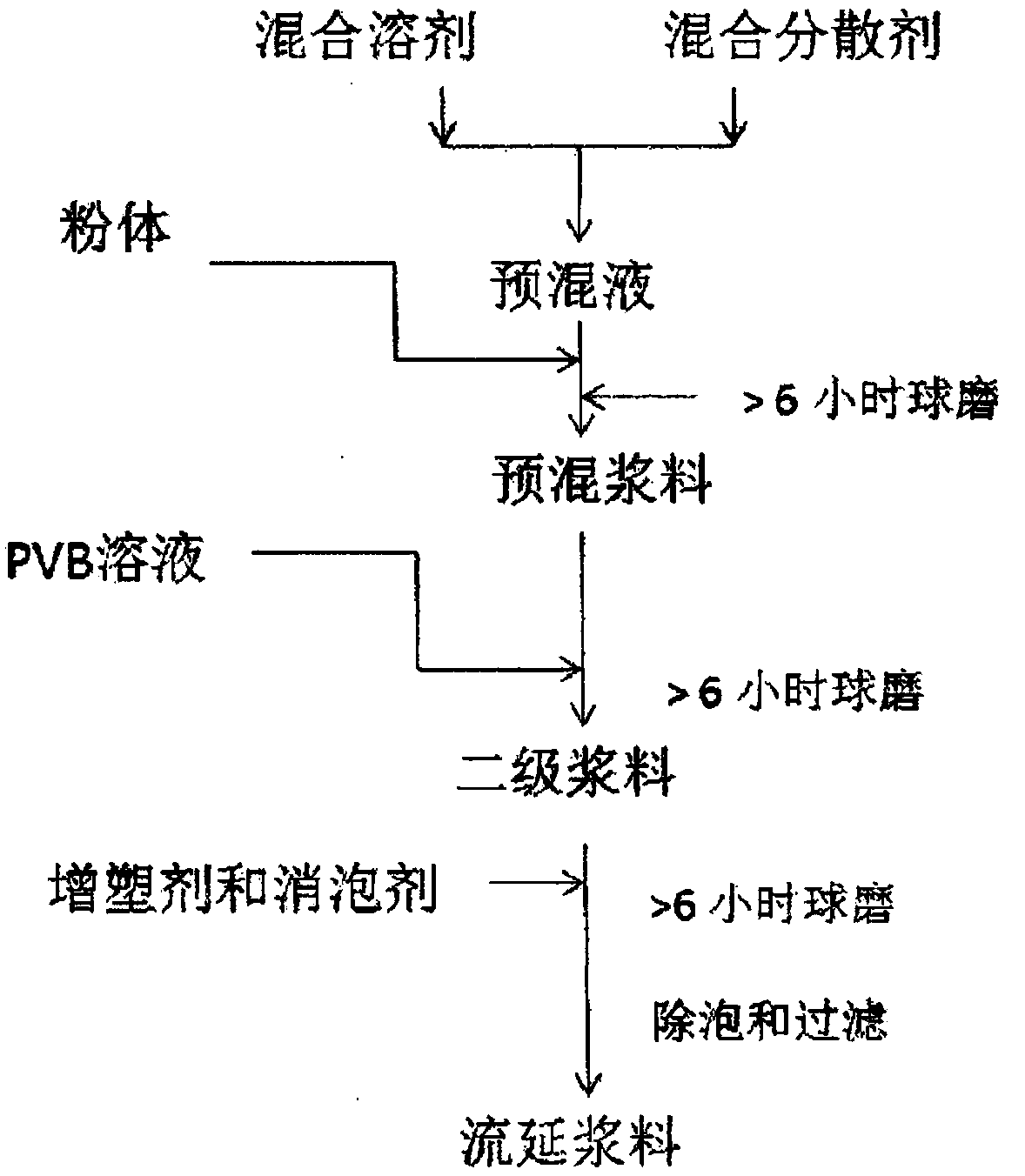

[0108] Preparation

[0109] The present invention provides a kind of preparation method of described ceramic slurry, is characterized in that, comprises the steps:

[0110] Provide the solid phase ceramic material and liquid phase components;

[0111] Wherein the mixed solvent is premixed with the mixed dispersant to obtain a premixed liquid;

[0112] The premixed liquid is mixed with the solid-phase ceramic material, and the premixed slurry is obtained af...

Embodiment 1

[0134] Get 200g fused silica powder (equivalent to 50 parts by weight), add 60g alcohol (15 parts by weight), 40g butanone (10 parts by weight), 2.5g castor oil, 2.1g glycerol and 2.0g triolein (dispersion The sum of the agents is 1.65 parts by weight). After ball milling for 12 hours (one night), 50 g of PVB solution was added, and its concentration was 25 g of PVB (6.25 parts by weight). 100 g of alcohol-butanone mixed solvent was added. After ball milling for 8 hours, 20 g of dibutyl phthalate (5 parts by weight of plasticizer) was added, and the milling was continued for 6 hours, then 2 g of tributyl phosphate was added for defoaming (0.5 parts by weight), and mixed for 4 hours. During casting, it is found that the fluidity of the slurry is good, the thickness of the film (cast sheet) is controllable, and the cast sheet is not easy to be crushed, which is beneficial to subsequent processing.

Embodiment 2

[0136] Take 140g dielectric glass powder (TC-3; Beixu Electronic Glass Co., Ltd.) and 60g (grams) fused silica powder (50 parts by weight); add 55g alcohol (13.75 parts by weight), 35g butanone (8.75 parts by weight), 2.5 g castor oil, 2.2g glycerol and 2g triolein (1.675 parts by weight), ball milled for 10 hours, then added 50gPVB solution (25gPVB / 125g solution) (equivalent to 2.5 parts by weight of binder), ball milled and mixed for 6 hours , then add 20g dibutyl phthalate (5 parts by weight plasticizer), mix for 4 hours, finally add 2g defoamer (0.5 parts by weight), mix for 4 hours, and make a cast sheet of 220 μm after casting , uniform thickness, good flexibility (break resistance) and tensile strength, in line with the general LTCC process requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com