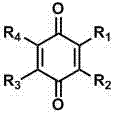

Separation / purification method of p-benzoquinone compound

A purification method, p-benzoquinone technology, applied in the field of separation/purification of p-benzoquinone compounds, can solve problems affecting product quality, large quinone-containing wastewater, carbonization and coking, etc., and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: The step is carried out according to Example 1 of the Chinese patent entitled "A Preparation Method of p-Benzoquinone Compound" (Application No.: 201410443854.7, submitted on September 3, 2014).

[0027] Step 2: Add 8.6 g of benzenetrifluoromethane (equivalent to 10% of the mass of the mixture) to the reaction mixture obtained in Step 1, stir at room temperature for 30 minutes, and then let it stand overnight. P-benzoquinone is precipitated and filtered to obtain P-benzoquinone 1.2g, yield 32%.

Embodiment 2-4

[0029] project Amount (g) Yield (%) 1. 15 38 2. 30 55 3. 45 63

Embodiment 5-8

[0031] project temperature( o c) Yield (%) 1. 50 35 2. 10 65 3. -30 72 4. -50 73

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com