Evaporator source, evaporation device and evaporation method

An evaporation source and evaporation technology, which is applied in the field of evaporation devices and evaporation sources, can solve the problems of reduction and waste of organic evaporation materials, yield and device performance, and achieve the effects of avoiding waste and good thickness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

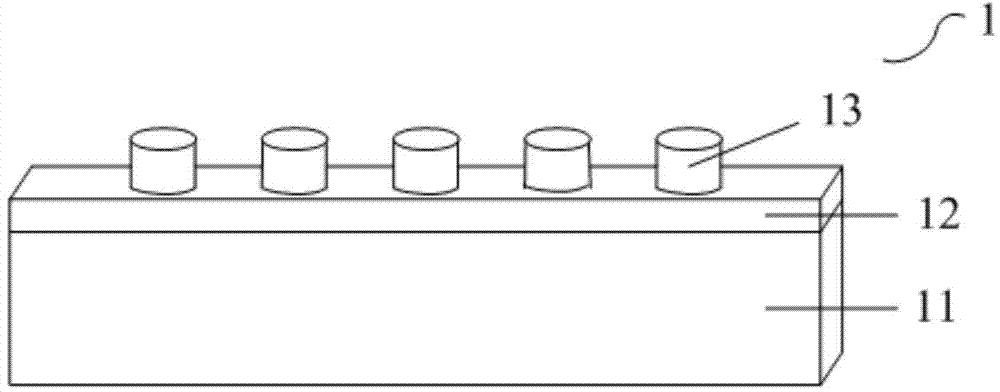

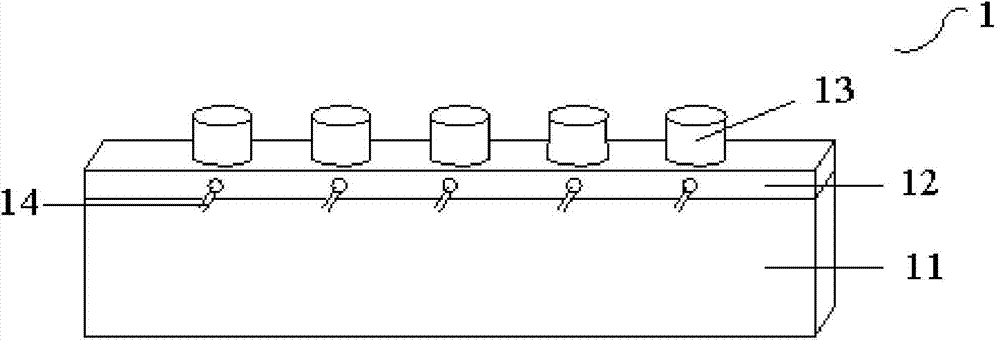

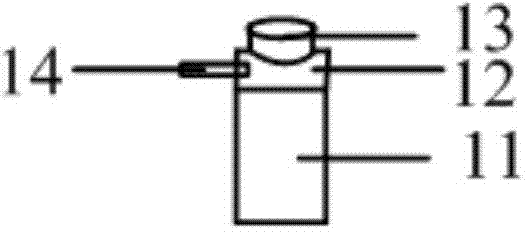

[0030] Such as figure 2 As shown, the present embodiment provides an evaporation source 1, which includes a crucible 11 for generating evaporation gas; a crucible nozzle 13 for ejecting the evaporation gas from the crucible 11; and a plugging heater 14 for The crucible nozzle 13 is heat-treated.

[0031] Preferably, the evaporation source 1 further includes a crucible top cover 12 , the crucible top cover 12 covers the crucible 11 , the crucible nozzle 13 is arranged on the crucible top cover 12 , and the plugging heater 14 is arranged in the crucible top cover 12 .

[0032] That is to say, a crucible top cover 12 can be covered on the crucible 11 that holds and heats the organic evaporation material, and the crucible top cover 12 is provided with a crucible nozzle 13. At this time, the plugging heater 14 can be buried in the crucible top cover The inside of 12 corresponds to the position of the crucible nozzle 13 .

[0033] Wherein, preferably, each crucible nozzle 13 corr...

Embodiment 2

[0038] Such as Figure 4 to Figure 6 As shown, the present embodiment provides a kind of evaporation source, and it has the structure similar to the evaporation source of embodiment 1, and its difference with embodiment 1 is that the plugging heater 14 is arranged on the crucible top cover 12 around the crucible nozzle 13 Location.

[0039] That is to say, the plugging heater 14 is arranged on the surface of the crucible top cover 12 , and the crucible nozzle 13 is enclosed in the plugging heater 14 .

[0040] Preferably, the blockage heater 14 is a ring heater, and the ring heater is composed of a plurality of heating plates arranged on the crucible top cover 12 for heating the crucible nozzle 13, and the heating plates Openings corresponding to the positions of the multiple crucible nozzles 13 are provided for covering the multiple crucible nozzles 13 .

[0041] Such as Figure 4 , Figure 5As shown, the circle heater takes a rectangular circle heater as an example, the ...

Embodiment 3

[0045] Such as Figure 7 As shown, the present embodiment provides an evaporation source, which has a structure similar to that of the evaporation sources of Embodiments 1 and 2, and its difference from Embodiments 1 and 2 is that the evaporation source 1 also includes a driving device 16, which blocks the heater 14 is arranged on the driving device 16, and the driving device 16 is used to drive the blocking heater 14 to move.

[0046] Such as Figure 7 As shown, the driving device 16 is arranged above the crucible 11 , the plugging heater 14 is arranged on the driving device 16 , and the driving device 16 can drive the blocking heater 14 to move. When the organic vapor deposition material to be evaporated was solidified in the crucible nozzle 13, the driving device 16 would drive the blocked heater 14 to move to the blocked crucible nozzle 13, and when arriving above the blocked crucible nozzle 13, the blocked heater 14 would directly The crucible nozzle 13 is heated to eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com