Mold inner surface electroplating production line and electroplating method

A technology of electroplating production line and crystallizer, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of large labor consumption, and the bottom end is nearly half of the size when the upper end is plated to the required size, and the waste of plating solution is large. Solve waste and environmental pollution, reduce labor intensity of workers, and solve the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] specific implementation plan

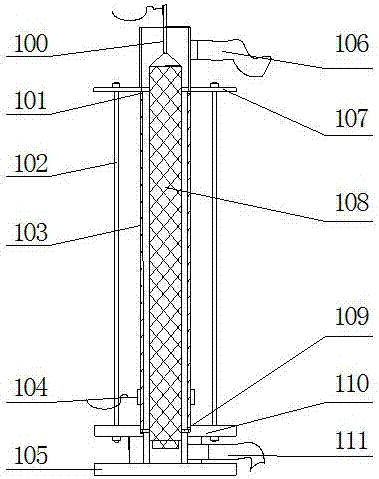

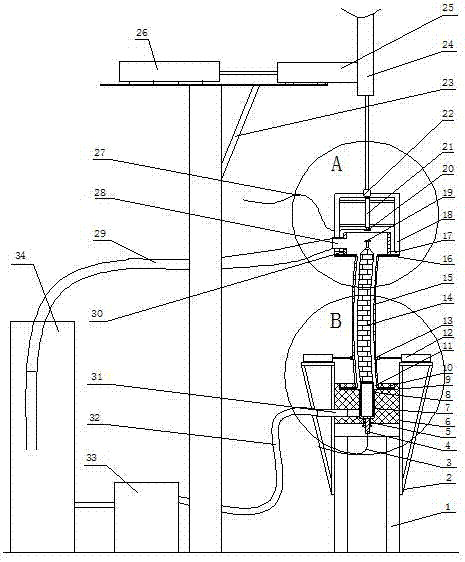

[0048] The production line of the present invention is mainly an improvement to the installation structure of the plating equipment in the crystallizer, such as figure 2 Shown is an installation structure for the inner surface electroplating equipment of the copper tube crystallizer.

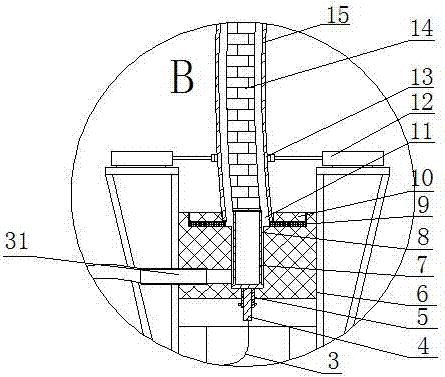

[0049] Such as figure 2 , image 3 As shown, a fixed base 6 is provided on the frame 1 , and a lower gasket 9 is arranged on the fixed base 6 . The lower gasket 9 is placed in the crystallizer positioning frame 11 provided in the center of the fixed base 6 . The copper tube crystallizer 15 is placed upright on the lower sealing gasket 9, and the lower sealing gasket pressing plate 10 is pressed against the lower sealing gasket 9 to increase the sealing effect and keep the position of the copper tube crystallizer 15 fixed. The cross-sectional shape of the fixed base 6 and the cross-sectional shape of the copper tube crystallizer 15 are both square. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com