Alkaline polishing solution for inhibiting galvanic corrosion of copper-ruthenium barrier layer and preparation method thereof

A technology of galvanic corrosion and polishing liquid, applied in polishing compositions, chemical instruments and methods, etc., can solve the problems affecting chip quality rate, yield and reliability, reducing Cu and Ru rates, galvanic corrosion microelectronics technology and other problems, to achieve the effect of solving serious galvanic corrosion problems, reducing current density and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Configure 1000g alkaline polishing liquid:

[0028] Take 100g of deionized water, add 10g β-hydroxyhexylethylenediamine, 1g ethylenediaminetetraacetic acid-tetra-tetrahydroxyethylethylenediamine, 30g O 11 -7((C 10 H 21 -C 6 H 4 -0-CH 2 CH 2 O) 7 -H), 3g H 2 O 2 , 100g of deionized water is diluted with 10g of phosphoric acid as a phosphoric acid regulator, and then 746g of deionized water is added while stirring.

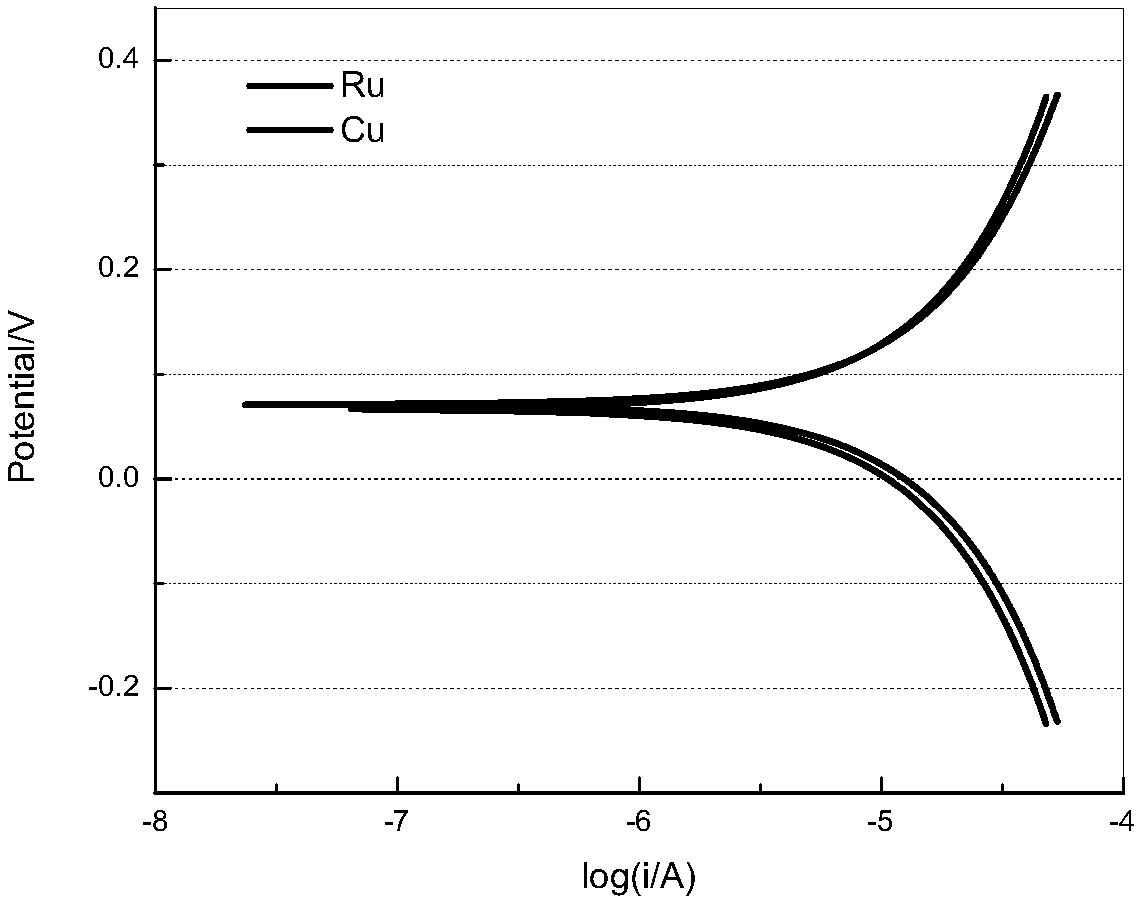

[0029] Such as figure 1 As shown, the potential difference between Ru and Cu is 2.8mv, which effectively suppresses galvanic corrosion between them.

Embodiment 2

[0031] Configure 1000g alkaline polishing liquid:

[0032] Take 100g of deionized water, add 30g β-hydroxyhexylethylenediamine, 1g ethylenediaminetetraacetic acid-tetra-tetrahydroxyethylethylenediamine, 15gO while stirring 11 -10((C 10 H 21 -C 6 H 4 -0-CH 2 CH 2 O) 10 -H), 15g0-20(C 12-18 H 25-37 -C 6 H 4 -0-CH 2 CH 2O ) 70 -H), 3g H 2 O 2 , 100g of deionized water to dilute 15g of phosphoric acid as a phosphoric acid regulator, and then add 721g of deionized water while stirring.

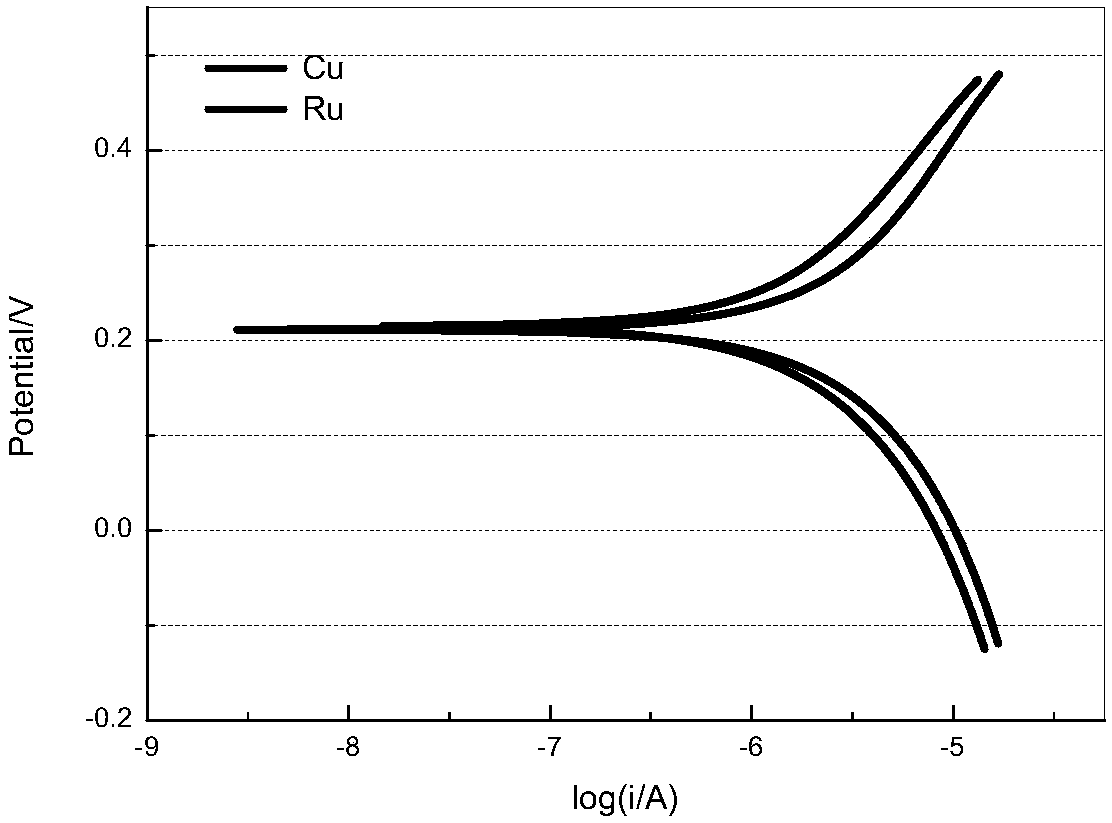

[0033] Such as figure 2 As shown, the potential difference between Ru and Cu is 5.29mv, which effectively inhibits galvanic corrosion between them.

Embodiment 3

[0035] Configure 1000g alkaline polishing liquid:

[0036] Take 100g of deionized water, add 10g β-hydroxyhexylethylenediamine, 3g ethylenediaminetetraacetic acid-tetra-tetrahydroxyethylethylenediamine, 30g fatty alcohol polyoxyethylene ether, 3g H 2 O 2 , 100g of deionized water to dilute 8g of phosphoric acid as a phosphoric acid regulator, and then add 746g of deionized water while stirring.

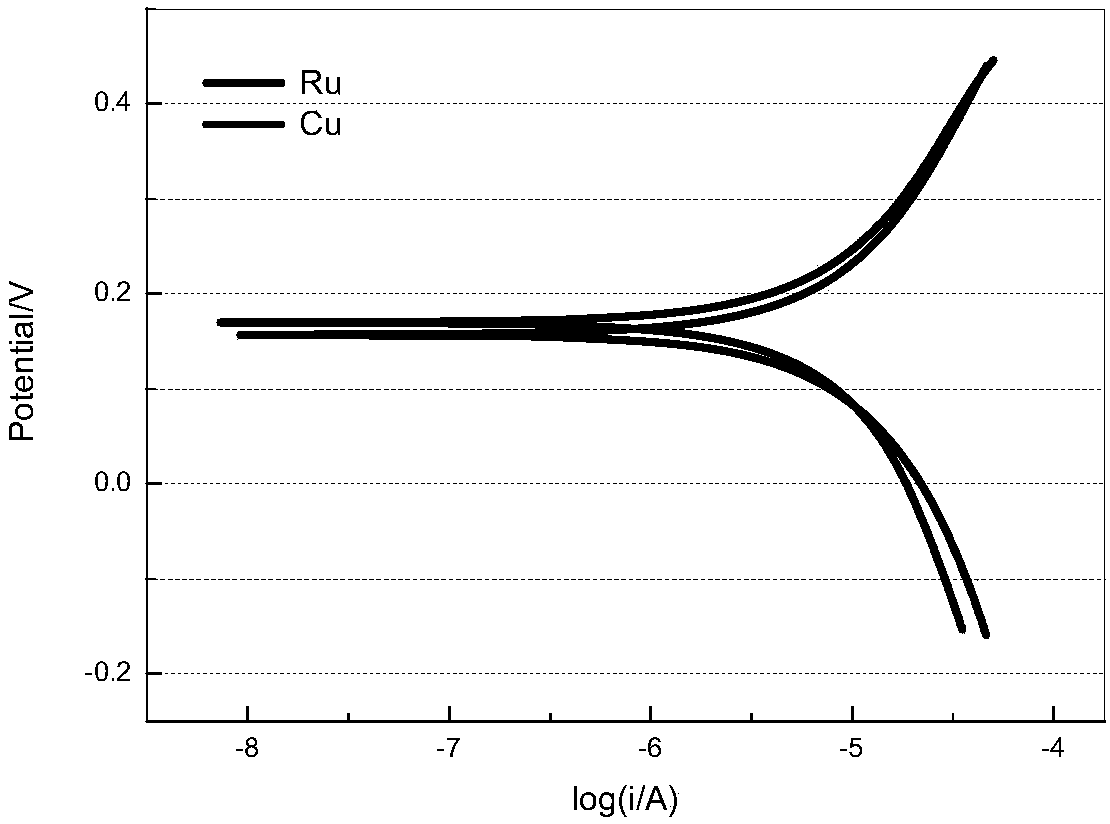

[0037] Such as image 3 As shown, the potential difference between Ru and Cu is 5.94 mv, which is beneficial to suppress the galvanic corrosion between them.

[0038] The process conditions of the polishing liquid application process in the foregoing Examples 1-3 are: the polishing head rotation speed is 87 rpm, the polishing disk rotation speed is 93 rpm, the working pressure is 2 psi, the polishing liquid volume flow rate is 150 v / ml, the polishing time is 6 min, and the polishing temperature is 22±0.5°C.

[0039] The working principle of the above alkaline polishing solution for inhibiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com