Pipeline anti-corrosion layer and anti-corrosion pipeline

A technology of anti-corrosion layer and pipeline, which is applied in the direction of pipeline anti-corrosion/rust protection, pipeline protection, pipe/pipe joint/pipe fitting, etc. It can solve the problems of electric corrosion of the pipeline body, affect the anti-corrosion effect, affect the insulation performance, etc., and achieve lightning resistance Or the impact current of the power grid into the ground, improve the anti-corrosion effect, and avoid the effect of concentrated damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

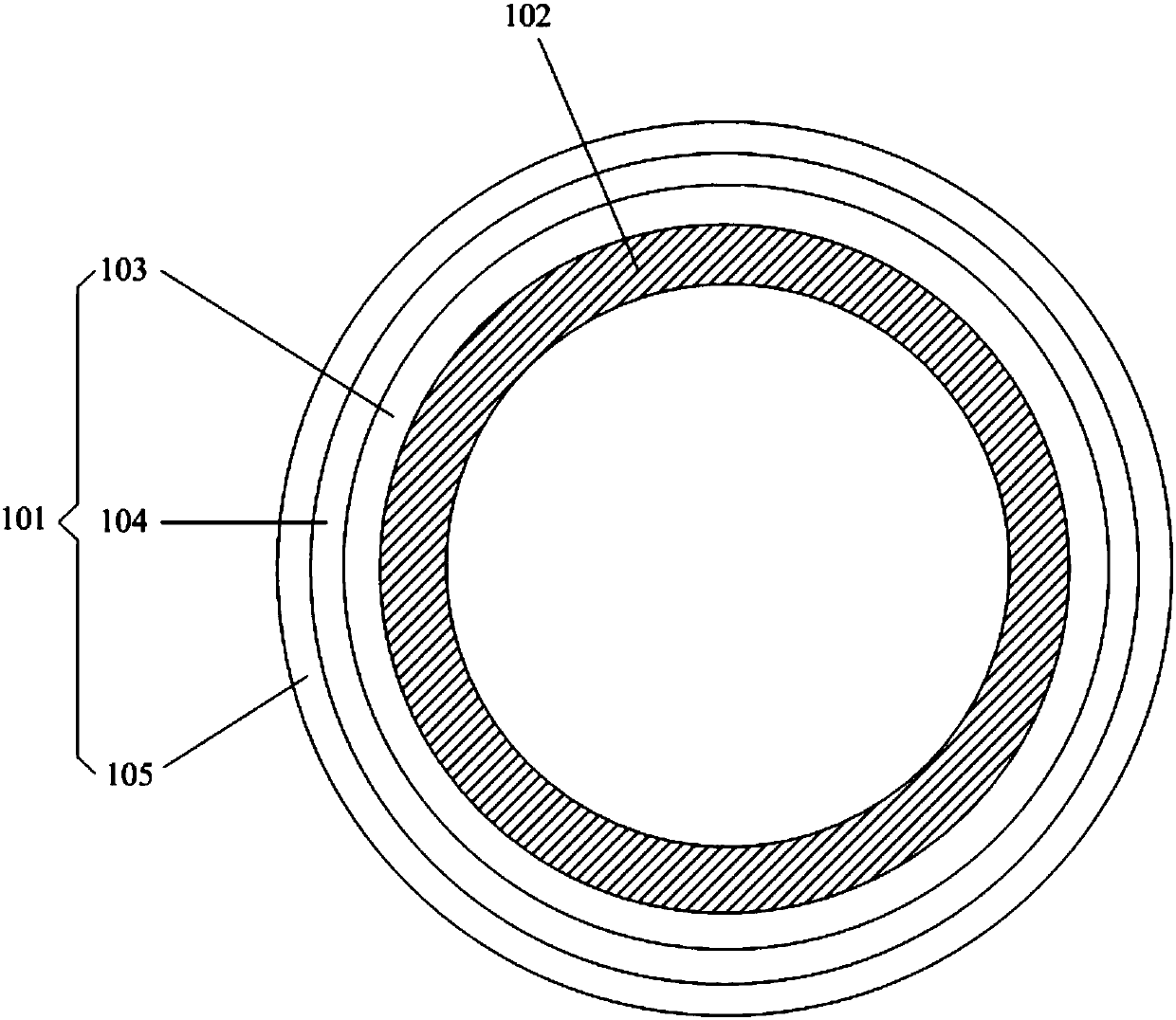

[0026] Please refer to figure 1 , the embodiment of the present invention provides a pipeline anticorrosion layer 101, the pipeline anticorrosion layer 101 is tubular and used to cover the outside of the pipe body 102, the pipeline anticorrosion layer 101 includes an inner semiconductive adhesive layer 103, an insulating layer 104 and The outer semiconductive adhesive layer 105, the inner semiconductive adhesive layer 103, the insulating layer 104 and the outer semiconductive adhesive layer 105 are sequentially arranged from inside to outside along the radial direction of the pipeline anticorrosion layer 101, and the inner semiconductive adhesive layer The conductive adhesive layer 103 and the outer semiconductive adhesive layer 105 are a uniform mixture of adhesive and semiconductive particles, and the inner semiconductive adhesive layer 103 and the outer semiconductive adhesive layer 105 are all bonded to the insulating layer 104. catch.

[0027] Specifically, the inner sem...

Embodiment 2

[0030] This embodiment provides a pipeline anti-corrosion layer, and the only difference from Embodiment 1 is:

[0031] The inner semiconductive adhesive layer is a homogeneous mixture of vinyl copolymer adhesive and carbon nanotubes (15:1 volume ratio), the insulating layer is a polyethylene material layer, and the outer semiconductive adhesive layer is vinyl copolymer adhesive A homogeneous mixture of viscose and titanium oxide (volume ratio 10:1).

[0032] The thickness of the inner semiconductive adhesive layer is 0.2 mm, the thickness of the insulating layer is 3.2 mm, and the thickness of the outer semiconductive adhesive layer is 0.6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com