A method for the overall lateral movement of the main girder of the mobile formwork

A technology for moving formwork and main girders, which is applied in the erection/assembly of bridges, bridges, bridge construction, etc. It can solve the problems of large mobile formwork, high site requirements, and difficult organization, so as to reduce safety risks and reduce material input. The effect of less and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

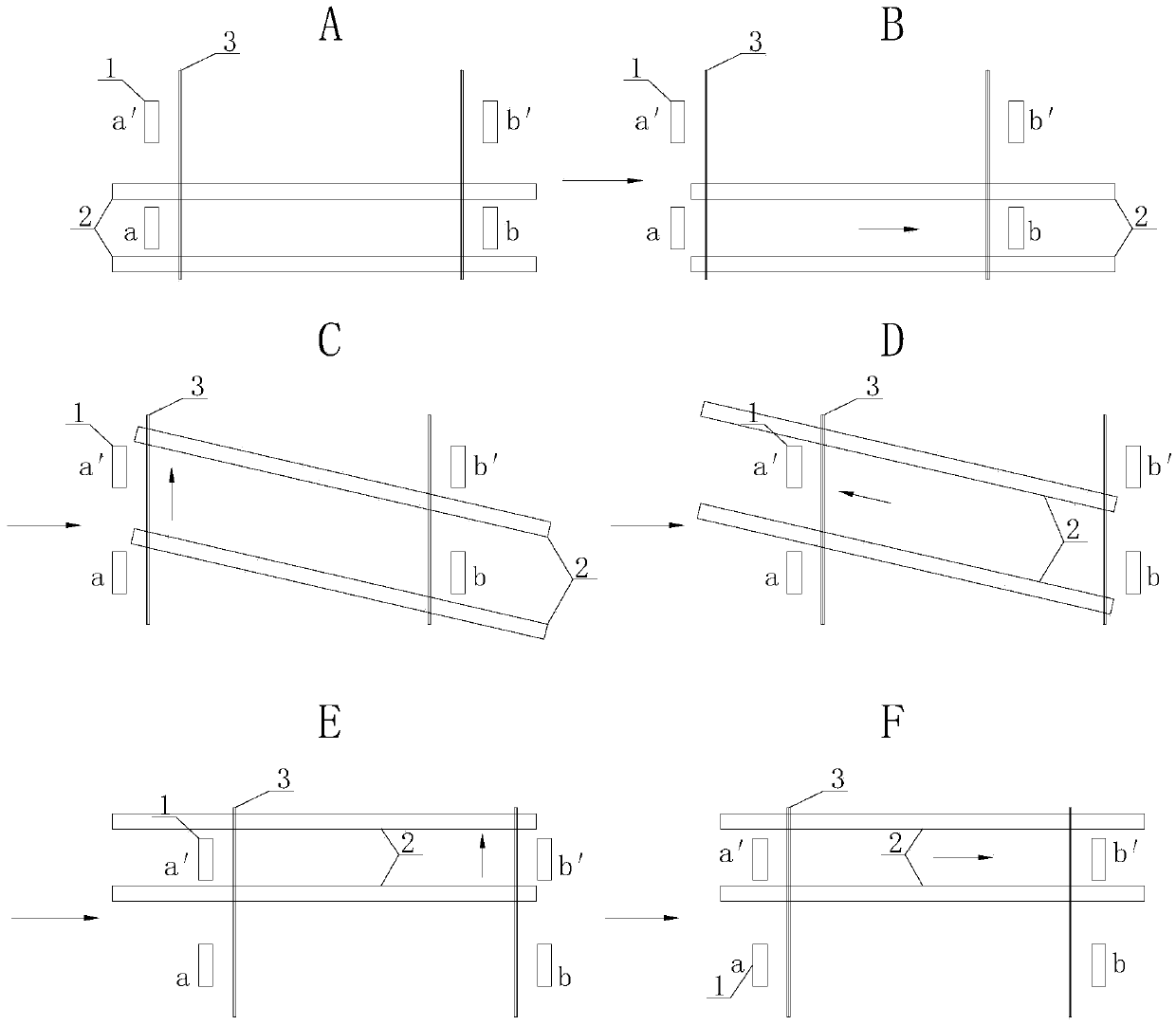

[0043] refer to figure 1 , 2 as shown, figure 1 The sequence of steps is from A to F, the first step: move forward vertically, the second step: move horizontally on one side, the third step: move vertically backward, the fourth step: move horizontally on the other side, the fifth step: move forward vertical shift. A method for the overall lateral movement of the main beam of the mobile formwork, which is used to move the main beam 2 of the mobile formwork spanning adjacent piers a and pier b to the position of pier a' and pier b' of the adjacent width, including in sequence The following steps:

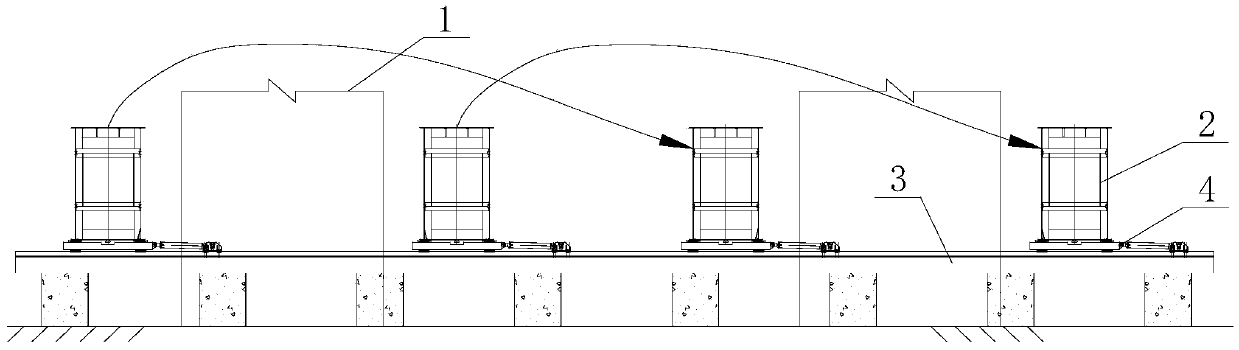

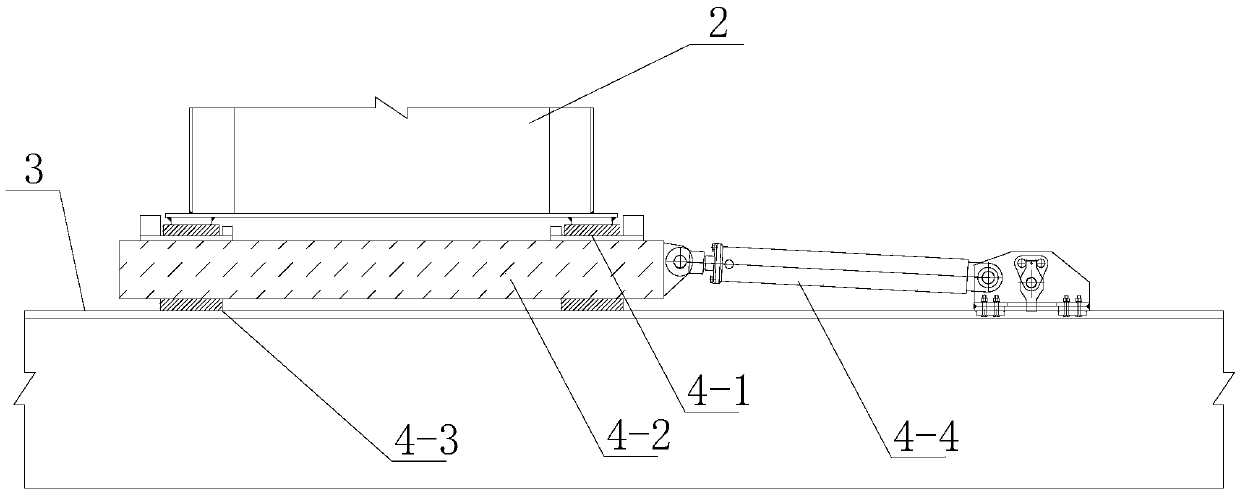

[0044] 1) Set up the traverse device: refer to image 3 , 4 As shown, the traversing device includes at least two parallel traversing rails 3 arranged between pier a and pier b, a slide system on the traversing rail 3, and a pushing device, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com