Flexible masonry filler wall and concrete structure connecting structure

A concrete structure and flexible connection technology, applied to walls, building components, building structures, etc., can solve the problems of inconvenient pouring of structural columns, inconvenient layout of doors, windows and openings, etc., so as to save project cost, reduce the effect of earthquake action, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

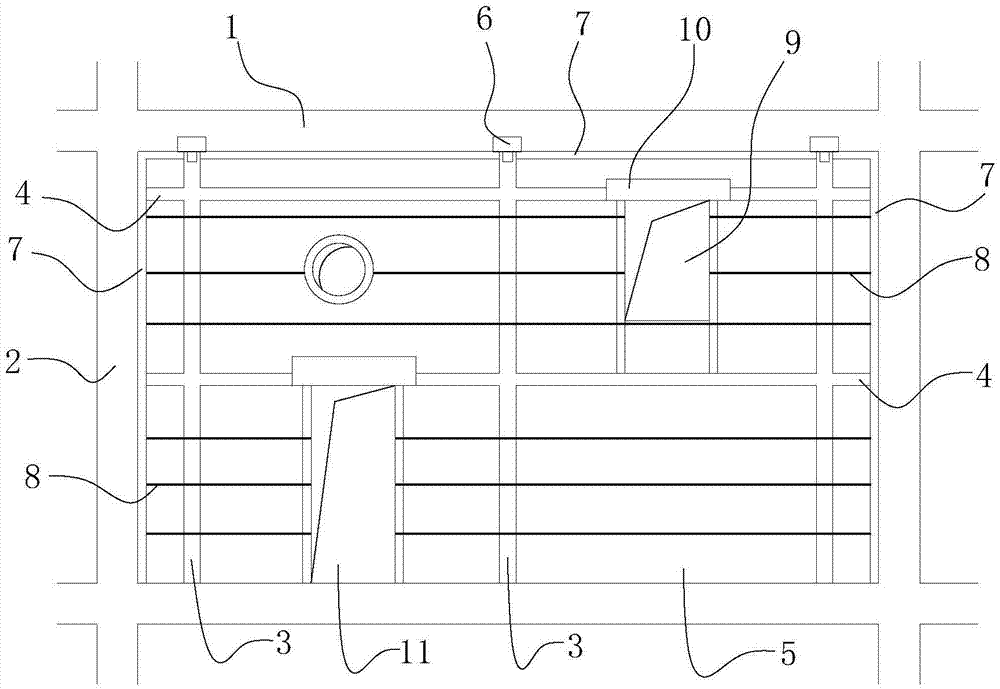

[0043] The application of the flexible connection structure between the masonry filling wall and the concrete structure in the main structure when the size of the door and window opening is ≤2100mm and the wall thickness is 200mm or 250mm. like figure 1 Shown is a schematic diagram of the flexible connection between the masonry infill wall and the concrete structure. The size of the door and window openings is ≤ 2100mm.

[0044] When the size of the door and window opening is ≤2100mm, such as figure 1 As shown in , select the appropriate masonry material for the infill wall according to the functional requirements of the building, and adjust the thickness value h of the masonry infill wall 5 and the opening ratio of the door and window openings on the wall to make the masonry height of the infill wall in Within the allowable height range shown in Table 1; then according to the seismic fortification intensity and basic wind pressure value of the building location, select the c...

Embodiment 2

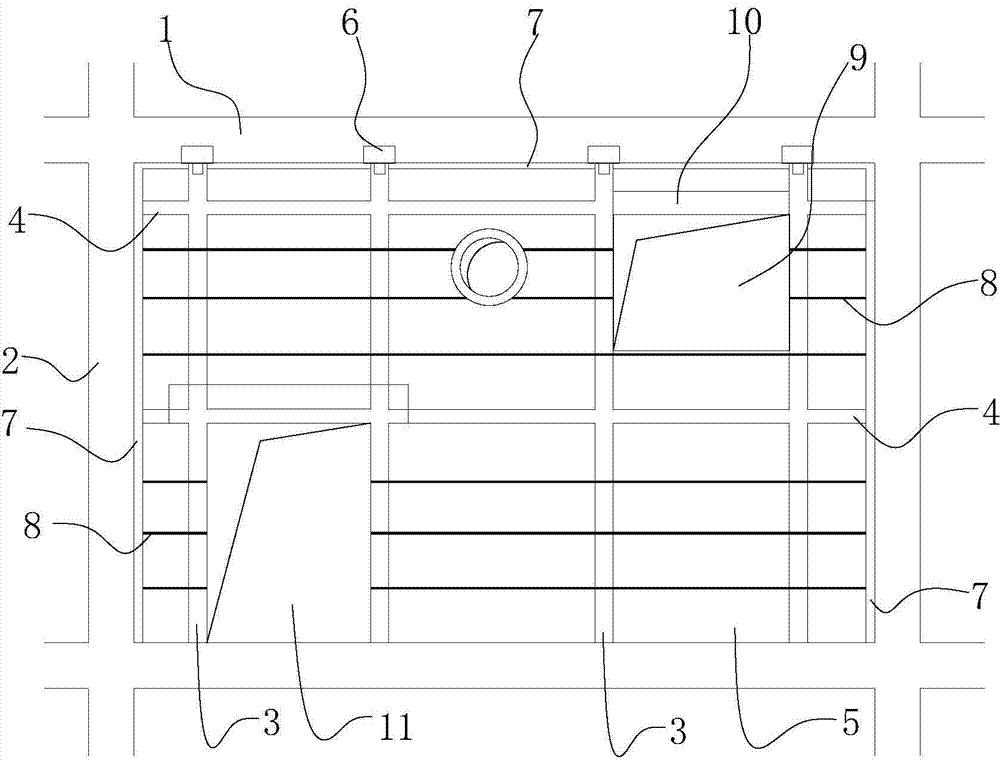

[0083] When the size of the door and window openings is greater than 2100mm, such as figure 2 As shown in the figure: the structural column 3 is set directly on both sides of the door and window opening. The structural method of the structural column 3 and the masonry infill wall 5 is the same as that of the door and window opening size ≤ 2100mm, and the connection between the masonry infill wall 5 and the main structure at other positions is exactly the same as that of the main structure. The size of door and window openings is less than or equal to 2100mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com