Aircraft airfoil surface structure

An aircraft and airfoil technology, applied in the aerospace field, can solve problems such as poor mechanical properties, and achieve the effects of good load-bearing performance, improved stability and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

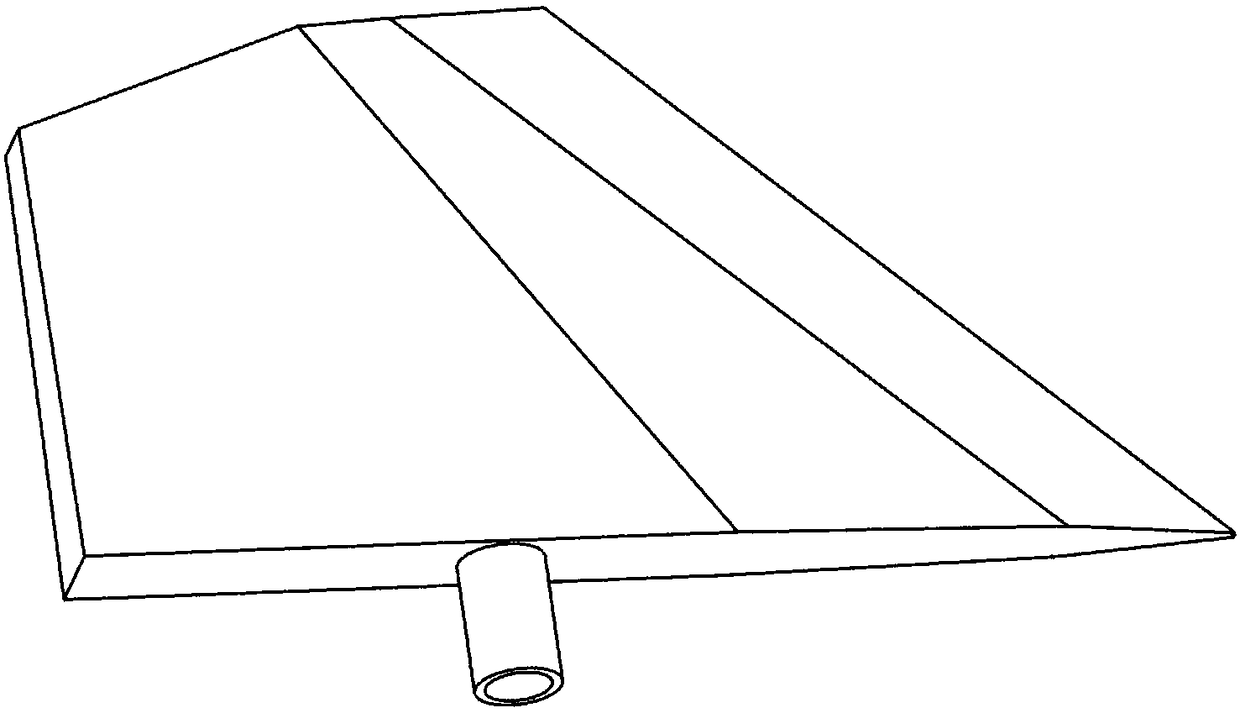

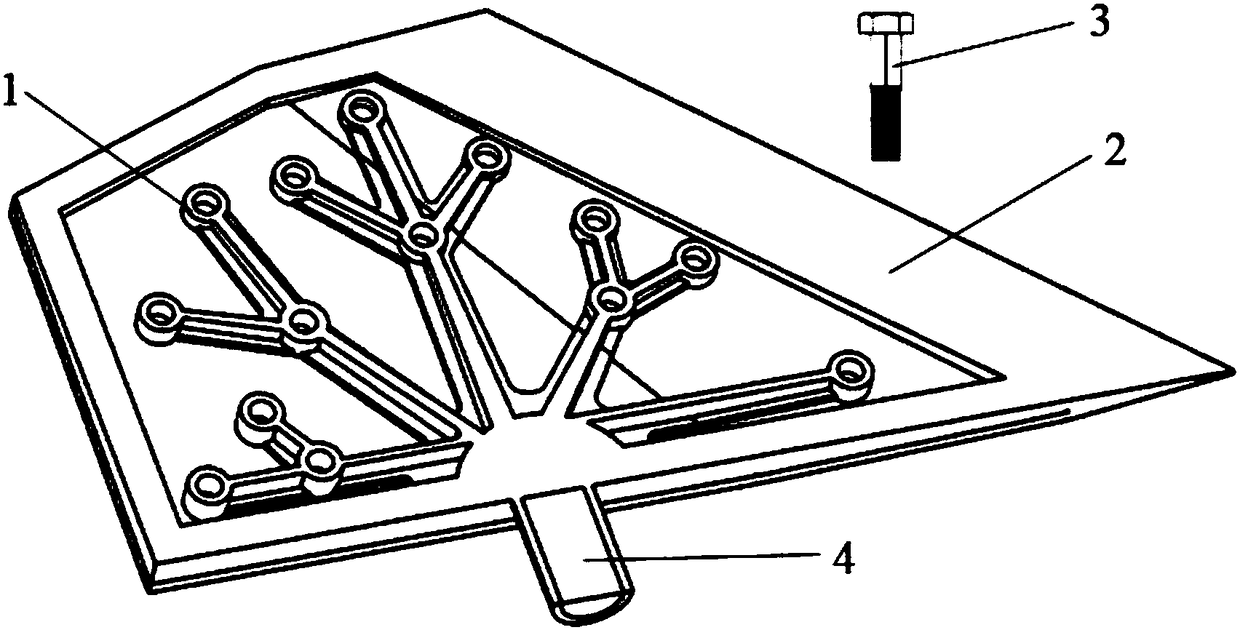

[0026] The airfoil structure of the aircraft of the present invention is used in the empennage part of the hypersonic aircraft, and acts as a control surface during the flight of the aircraft to realize the maneuvering flight of the aircraft. figure 1 is the overall schematic diagram of the airfoil structure, figure 2 yes figure 1 A schematic cross-sectional view of the airfoil structure shown.

[0027] The airfoil structure of a hypersonic vehicle adopts a tree-shaped metal inner core and a composite material skin, and its characteristics include an inner core 1 , a skin 2 , bolts 3 , and a rudder shaft 4 . The inner core 1 adopts a tree-like I-beam structure and is made of GH4099 superalloy; the inner core 1 is provided with bolt holes at the branches and ends of the tree-like structure; the skin 2 is made of C / SiC composite material Manufactured and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com