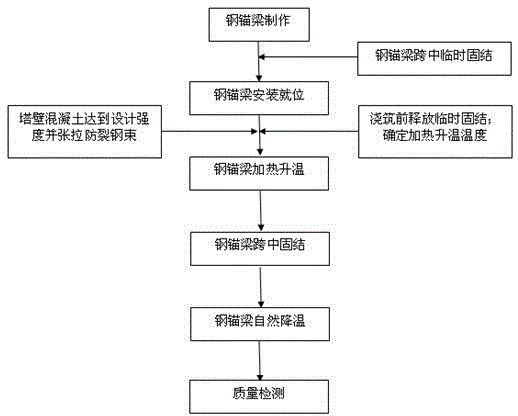

Method for exerting pre-stress to bracket-free steel anchor beam in electrically-heating mode

A steel anchor beam and prestressing technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low stiffness, small horizontal component force ratio of stay cables, and inability to reflect the effect of steel anchor beams, etc., to achieve Improve the effect of structural stress, simple equipment operation, and clear force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

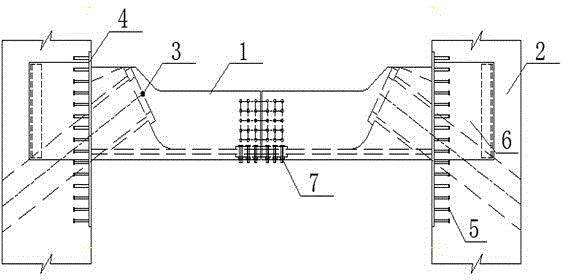

[0056] The main bridge of a certain bridge is a prestressed concrete cable-stayed bridge with five spans, two towers and two cable planes. The span of the main span is 360m. The standard section length of the main girder of the main bridge is 6m. , the design adopts a anchorage form of a corbelless steel anchor beam cable tower, such as figure 2 shown. The steel anchor beam of No. 3 main tower section No. 28 with the largest horizontal component force of the stay cables is selected, and Q345D steel is used. The maximum cable force of the stay cable J28 on the river side is 6146kN in the completed bridge state, and the maximum cable force of the stay cable A28 on the bank side is 6764kN, the stay cables are designed according to the asymmetric load. The middle span of the No. 28 section steel anchor beam is an open box section with an area of 86920mm 2 , the horizontal angles of stay cables J28 and A28 are 31.042 and 31.493 respectively, and the distance between anchor poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com