Nuclear power CB20 module integral splicing transportation platform

A CB20, transportation platform technology, applied in construction, building structure, construction material processing, etc., can solve the problems of difficult construction, thin tank wall structure, and humid air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

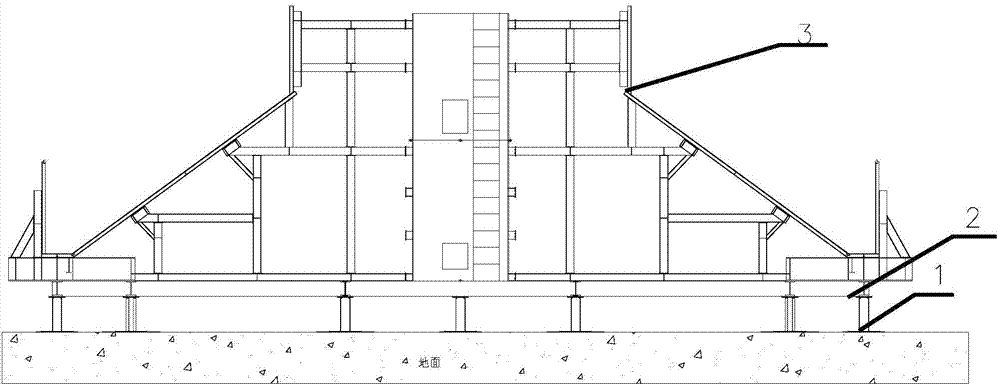

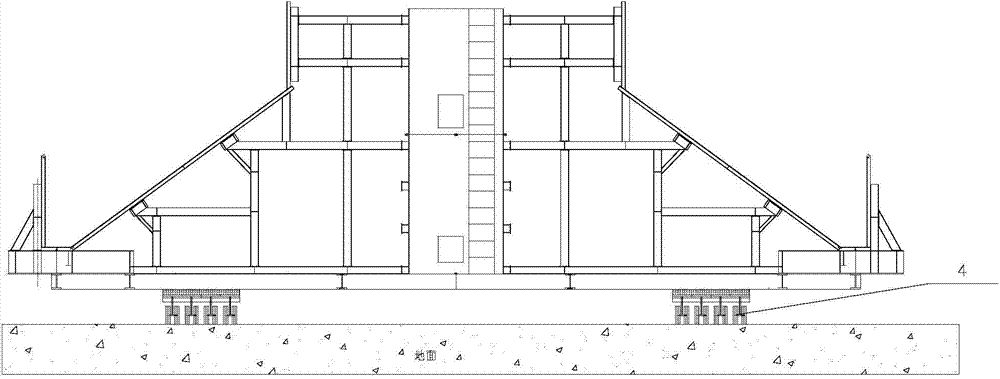

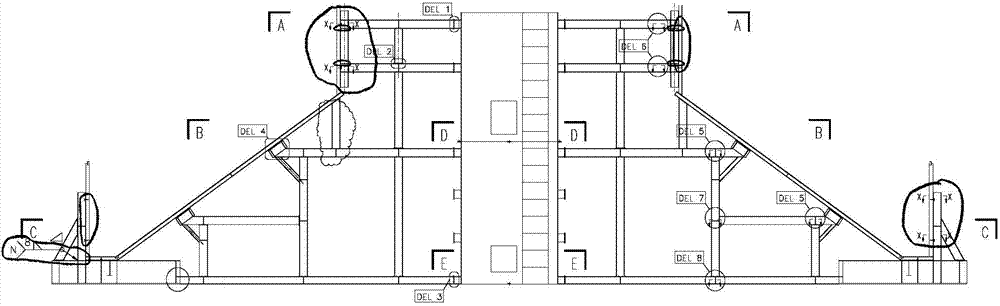

[0050] refer to Figure 1 to Figure 9 , the nuclear power CB20 module overall assembled transport platform, including the bottom detachable column support 1, the middle part of the assembled transport platform body 2 and the uppermost module support tire frame 3, the assembled transport platform body 2 is used The support module supports the tire frame 3, and when the CB20 module is transported as a whole, the assembled transport platform body 2 is transported together with the CB20 module;

[0051] The supporting column 1 is composed of a steel column bottom plate fixedly connected from bottom to top, a double I-beam and a steel column top plate. The steel column bottom plate is detachably fixed on the concrete floor. The top plate of the column is connected with the 2 bolts of the assembled transportation platform body;

[0052] The assembled transportation platform body 2 includes main beams 21 and secondary beams 22, the main beams 21 are arranged horizontally and vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com