Compression ignition engine and low-pressure low-temperature ignition and exhaust pollution elimination method

A technology for engines and compressed air, which is applied to combustion engines, internal combustion piston engines, engine components, etc., and can solve problems such as white smoke and black smoke from compression ignition engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

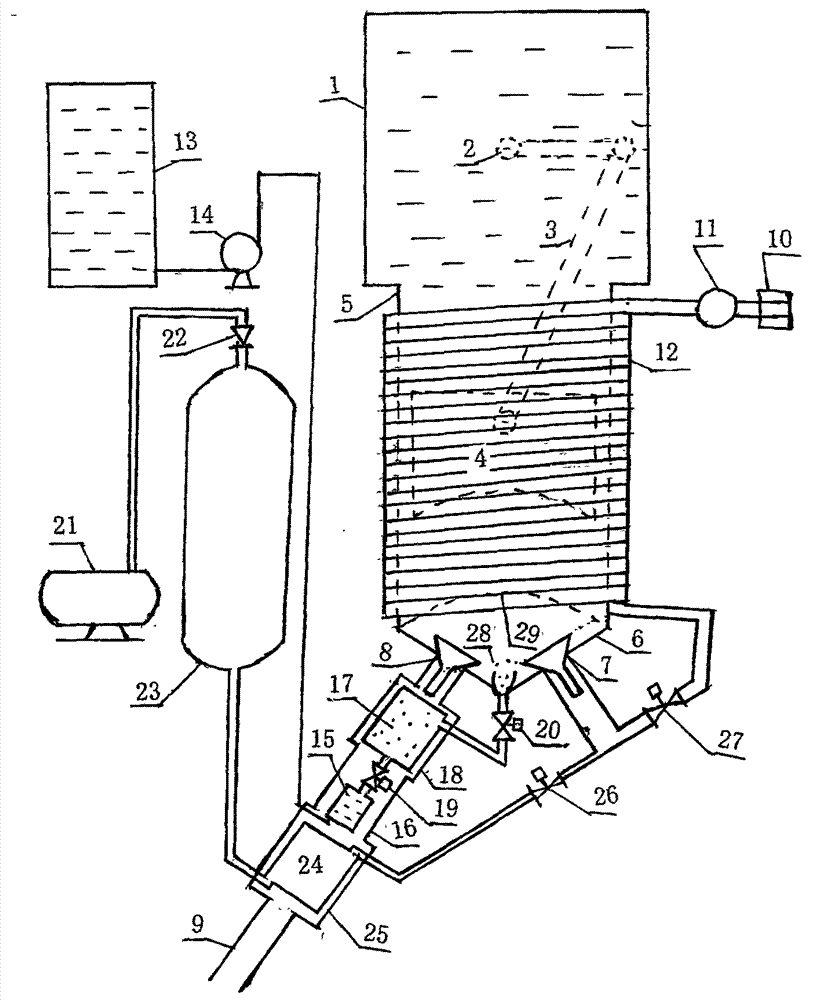

[0011] figure 1 Shown, a compression ignition engine. The compression ignition engine structure mainly includes: crankcase 1, crankshaft 2, crank 3, piston 4, cylinder 5, cylinder head 6, intake valve 7, exhaust valve 8, exhaust pipe 9, air filter 10, supercharger Fan 11, cylinder air-cooled coil 12, fuel tank 13, fuel pump 14. The crankcase 1 is lubricated with organic oil, and the cylinder 5 is covered with a cylinder air-cooled coil 12. After passing through the air filter 10, the air is blown into the cylinder air-cooling coil 12 by the booster fan 11, and then enters the intake pipe after passing through an electromagnetic air valve 27 and a tee, and finally enters the cylinder 5 through the opened intake valve 7. The compressed air extruded by the air compressor 21 enters the compressed air storage tank 23 after passing through the check valve 22 . The compressed air storage tank 23 is equipped with a pressure sensor. The compressed air coming out from the compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com