Non-contact automatic gas sample retention device

A non-contact, fully automatic technology, applied in the direction of sampling devices, etc., can solve the problems of heating gas or air bag safety accidents, inaccurate verification and analysis results, and large labor costs, so as to save labor costs and improve production safety sex, the effect of eliminating mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

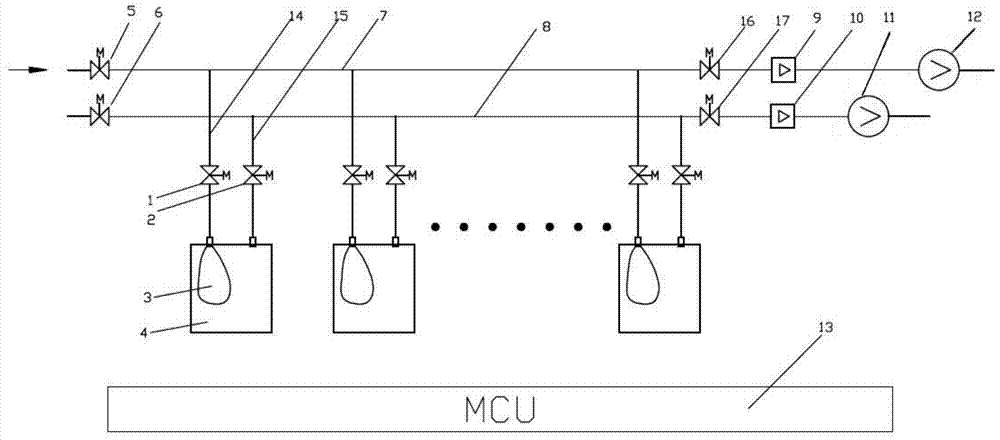

[0035] Example: Combine figure 1 Shown is a specific embodiment of the non-contact fully automatic gas sample retention device of the present invention, which has sampling pipes 7 and air pipelines 8 arranged in parallel, wherein:

[0036]The sampling pipe 7 is provided with a sample gas valve 5, an evacuation flowmeter 9 and an air pump 12 in sequence, and the sampling pipe 7 between the sample gas valve 5 and the evacuation flowmeter 9 is provided with an air bag connection area, which A plurality of gas bags 3 are connected through the sample gas branch pipe 14, and each sample gas branch pipe 14 is provided with a communication valve 1. And described air pipeline 8 is provided with air valve 6, sampling flowmeter 10 and sampling air pump 11 successively, and is provided with vacuum box connection area on air pipeline 8 between air valve 6 and sampling flowmeter 10, its There are several vacuum boxes 4 corresponding to the aforementioned airbags 3 one by one connected thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com