A method for detecting the quality of the inner wall of a pcb via hole

A detection method and quality technology, applied in measuring devices, material analysis through optical means, image data processing, etc., can solve problems such as the inability to guarantee the quality of PCB products and the inability to detect the inner wall of the hole, so as to improve the stability of product performance, Guarantee product quality and realize the effect of improving profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

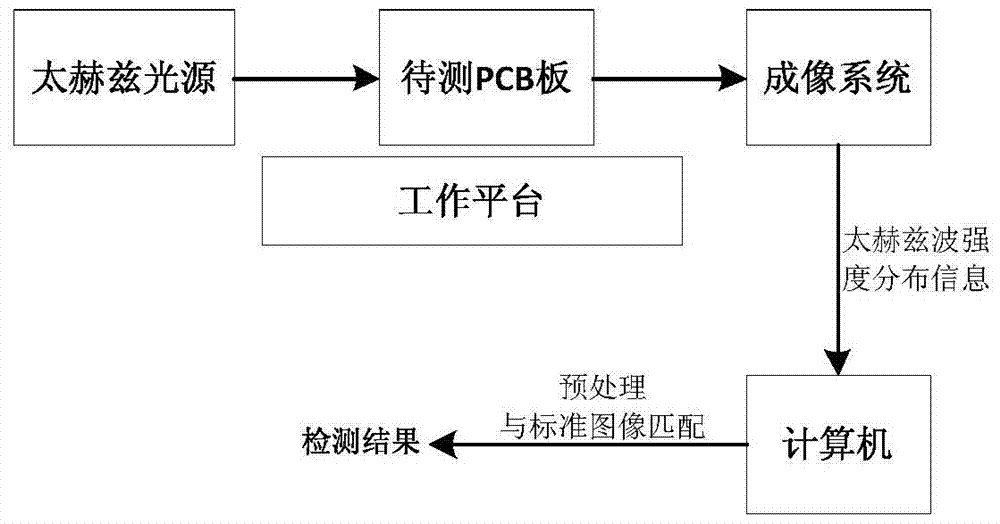

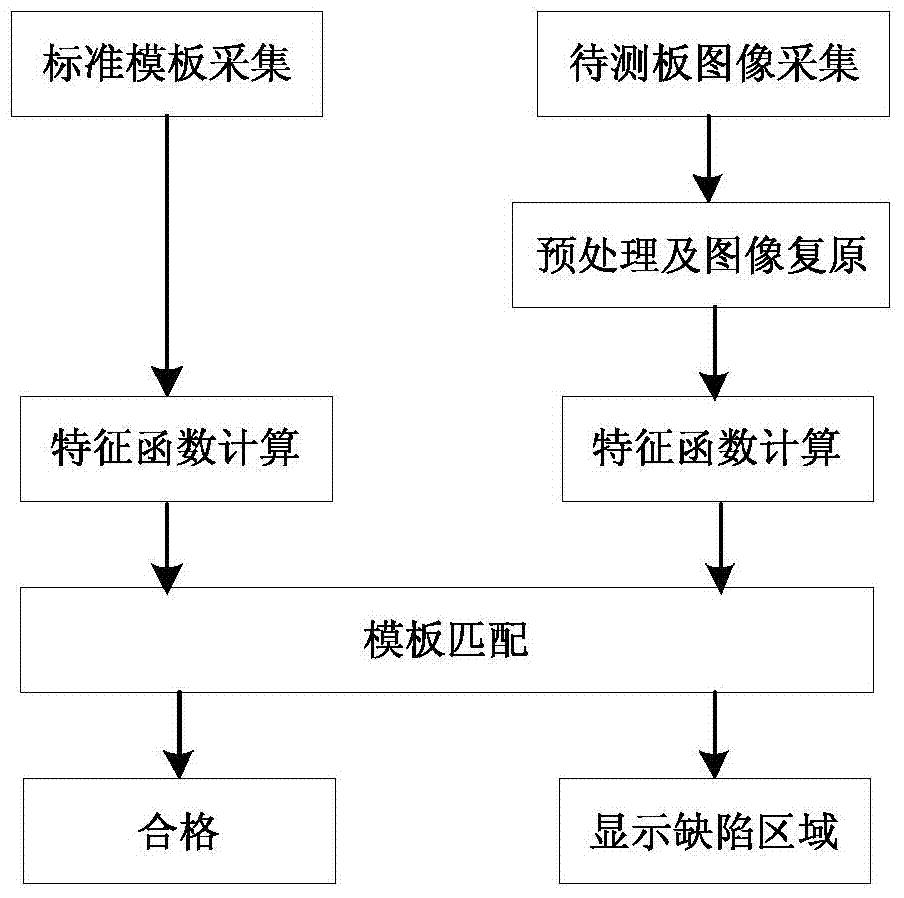

[0052] refer to Figure 1 ~ Figure 3 , a kind of detection method of PCB through-hole inner wall quality, described detection method comprises the steps:

[0053] Step 101: Obtain the PCB to be tested and a standard template;

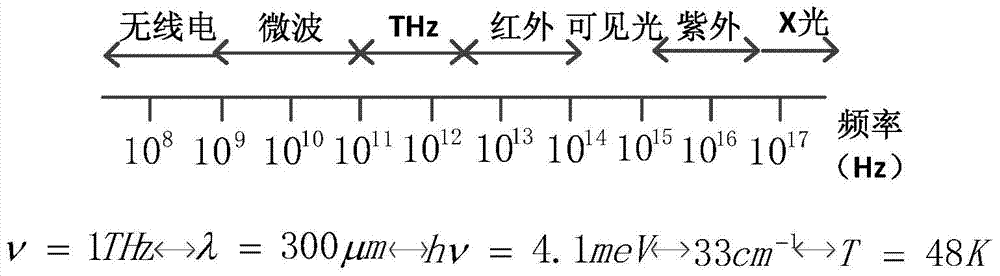

[0054] Step 102: Using terahertz wave imaging technology to collect the original image of the PCB to be tested and the original image of the standard template;

[0055] Step 103: Perform thresholding and denoising processing on the original image of the PCB to be tested and the original image of the standard template to obtain the restored image to be tested and the restored image of the standard template;

[0056] Step 104: Calculate the characteristic functions of the restored image of the standard template and the restored image to be tested respectively, and obtain the center and aperture information of the via hole. The process is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com