Liquid crystal display panel and manufacture method and display device thereof

A technology of a liquid crystal display panel and a manufacturing method, which are applied in the directions of nonlinear optics, instruments, optics, etc., can solve the problems of reduced transmittance, light leakage of the liquid crystal display panel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

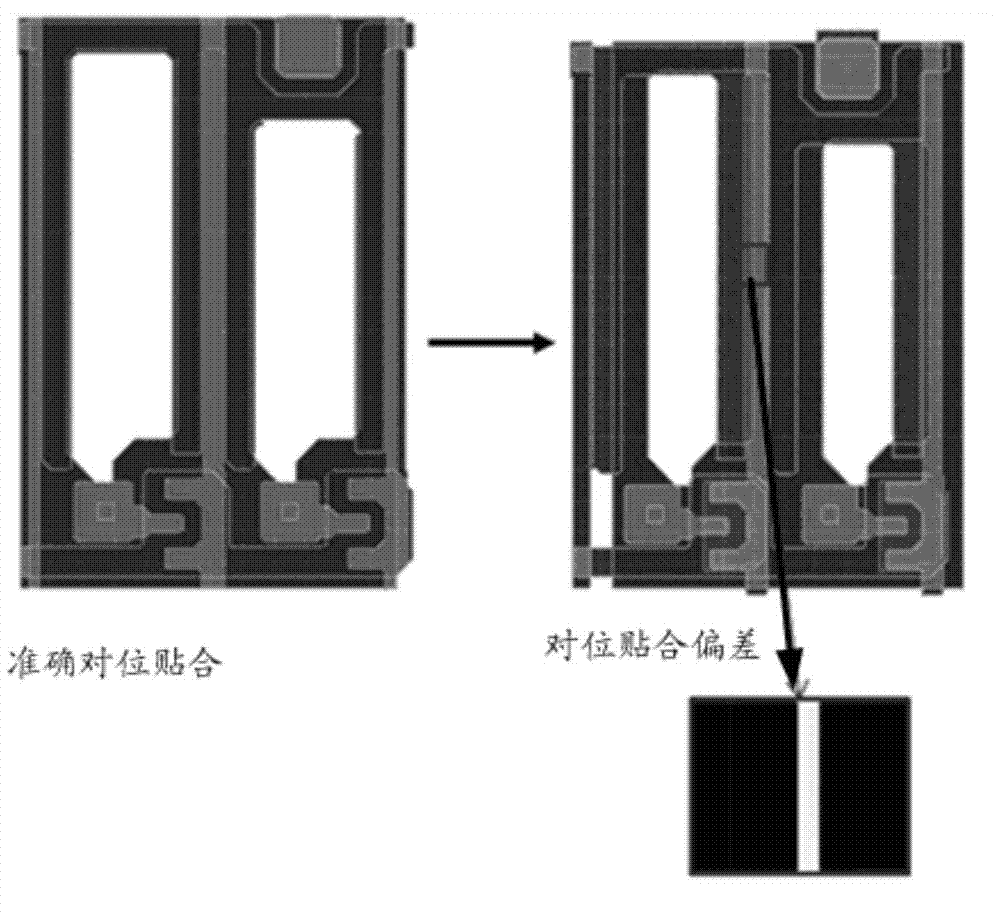

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Liquid crystal display panel in twisted nematic (Twist Nematic, TN) mode

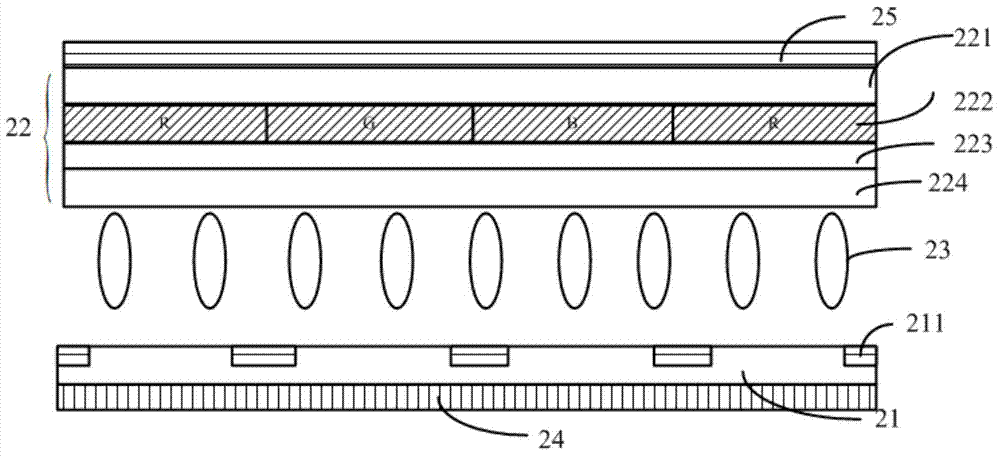

[0044] like figure 2 As shown, it is a schematic structural diagram of a liquid crystal display panel in TN mode provided by an embodiment of the present invention. The liquid crystal display panel mainly includes: an array substrate 21, a color filter substrate 22 arranged oppositely, and a The liquid crystal layer 23 between the color filter substrates 22, the first polarizer 24 arranged on the side of the array substrate 21 away from the color filter substrate 22, the first polarizer 24 arranged in the color filter substrate 22 away from the The second polarizer 25 on one side of the array substrate 21 , the first polarizer 24 is perpendicular to the polarization direction of the second polarizer 25 .

[0045] Wherein, the color filter substrate 22 involved in the embodiment of the present invention is arranged in sequence from far to near to the array substrate 21: a first bas...

Embodiment 2

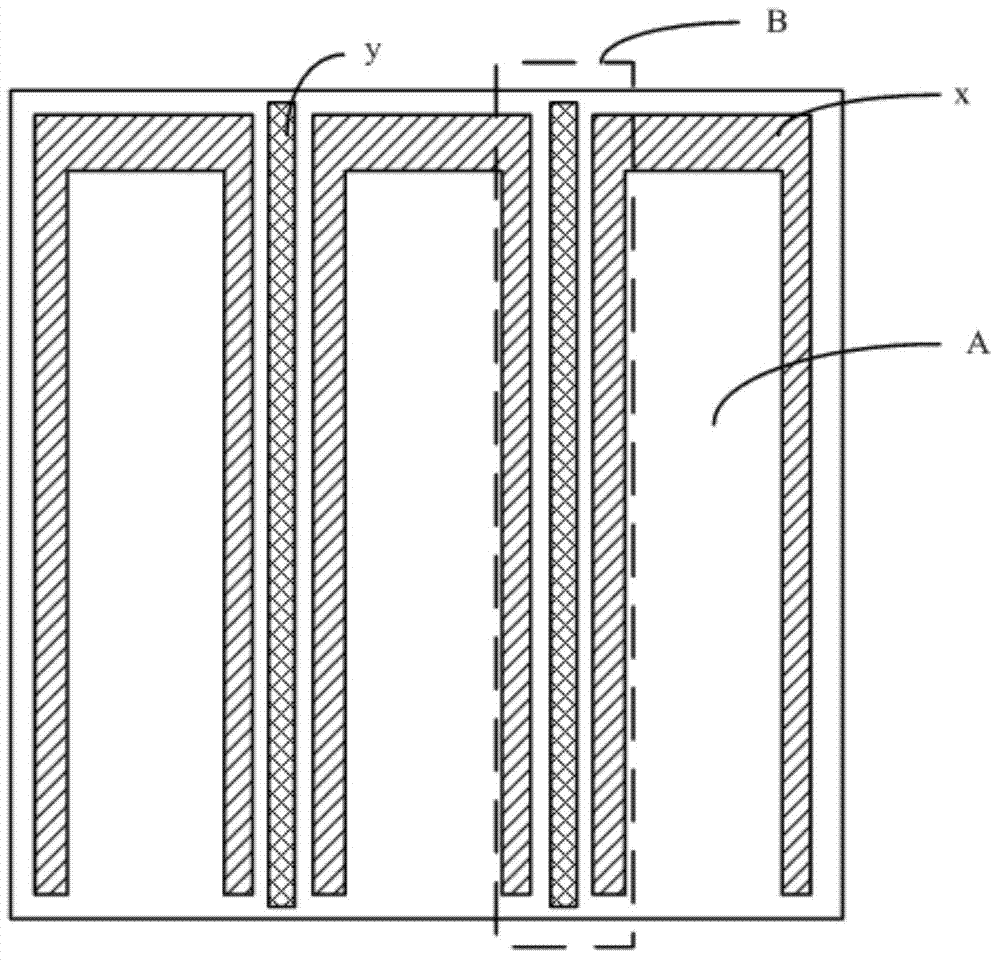

[0067] Embodiment 2: LCD panel in ADS mode

[0068] like Image 6As shown, it is a schematic structural diagram of a liquid crystal display panel in TN mode provided by an embodiment of the present invention. The liquid crystal display panel mainly includes: an array substrate 61, a color filter substrate 62 arranged oppositely, and a The liquid crystal layer 63 between the color filter substrates 62 , the first polarizer 64 arranged on a side of the array substrate 61 away from the color filter substrate 62 , the first polarizer 64 arranged in the color filter substrate 62 away from the The second polarizer 65 on one side of the array substrate 61 , the first polarizer 64 is perpendicular to the polarization direction of the second polarizer 65 .

[0069] Wherein, the color filter substrate 62 involved in the embodiment of the present invention is arranged in sequence from far to near to the array substrate 61: a first transparent electrode 624, a first base 621, a color pho...

Embodiment 3

[0090] An embodiment of the present invention also provides a display device, including any one of the liquid crystal display panels mentioned above. Wherein, the display device may be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com