Kelp knot tying machine and knot tying method

A kelp knotting machine and kelp technology are applied in applications, food preparation, food science, etc. It can solve the problems of low knotting success rate, low knotting efficiency, and nail peeling, and achieve simple and fast maintenance and improve knotting efficiency. , promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

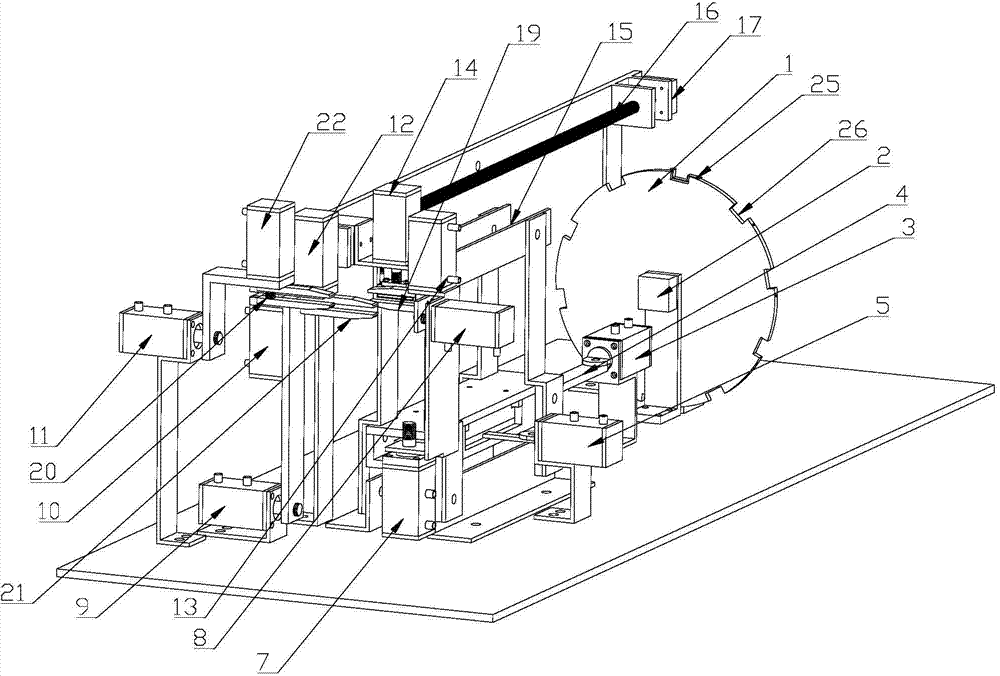

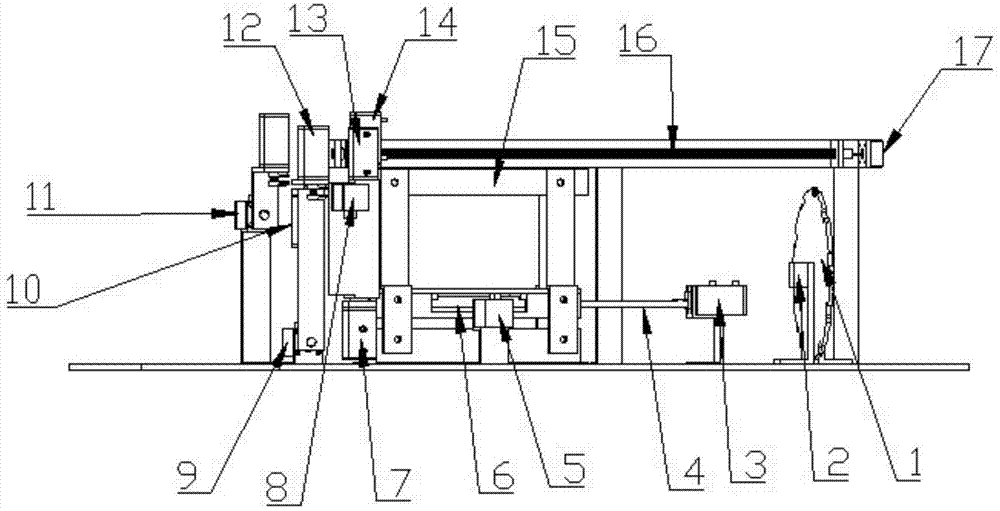

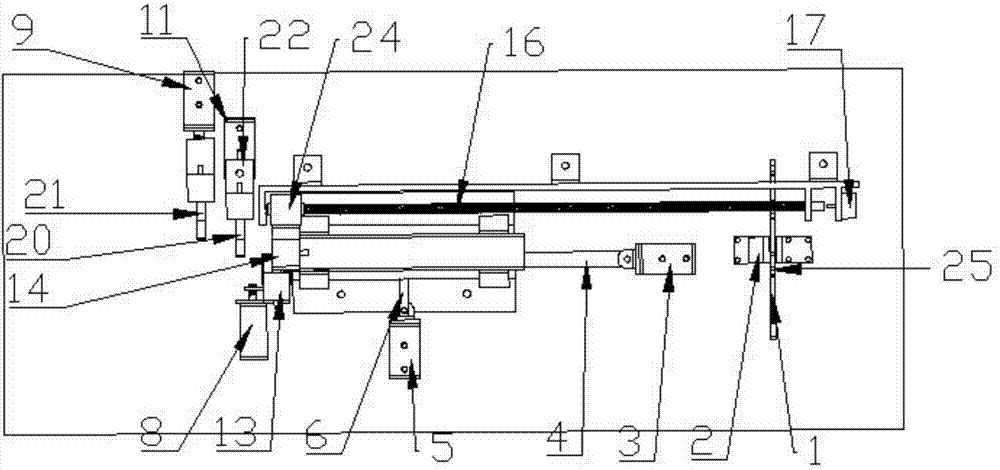

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] The kelp knotting machine includes a frame, a PLC control system and a pneumatic control system. The frame is equipped with a feeding device, a material conveying device, a knotting device and a cutting device:

[0037] Feeding device, the feeding device includes a bracket installed on the frame of the kelp knotting machine through the bracket, a feeding disc 1 is installed on the bracket, and the feeding disc 1 is connected with a stepping motor 2, and the stepping motor 2 drives the upper The material disc 1 rotates; there is a notch 26 along the circumferential edge of the feeding disc 1, and an elastic pressing piece 25 is installed at the notch 26; The circumference of the notch is pushed down by the elastic pressing piece 25 at the notch 26, fixed, and it is transported to the designated height position by the feeding disc 1.

[0038] The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com