Smoke generator assembling method

A smoke generator and assembly method technology, applied in tobacco, smoker supplies, applications, etc., can solve the problems of complex assembly process, waste, and affect the uniformity of heating, etc., to achieve simple structure assembly, high production efficiency, and reduce defects rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

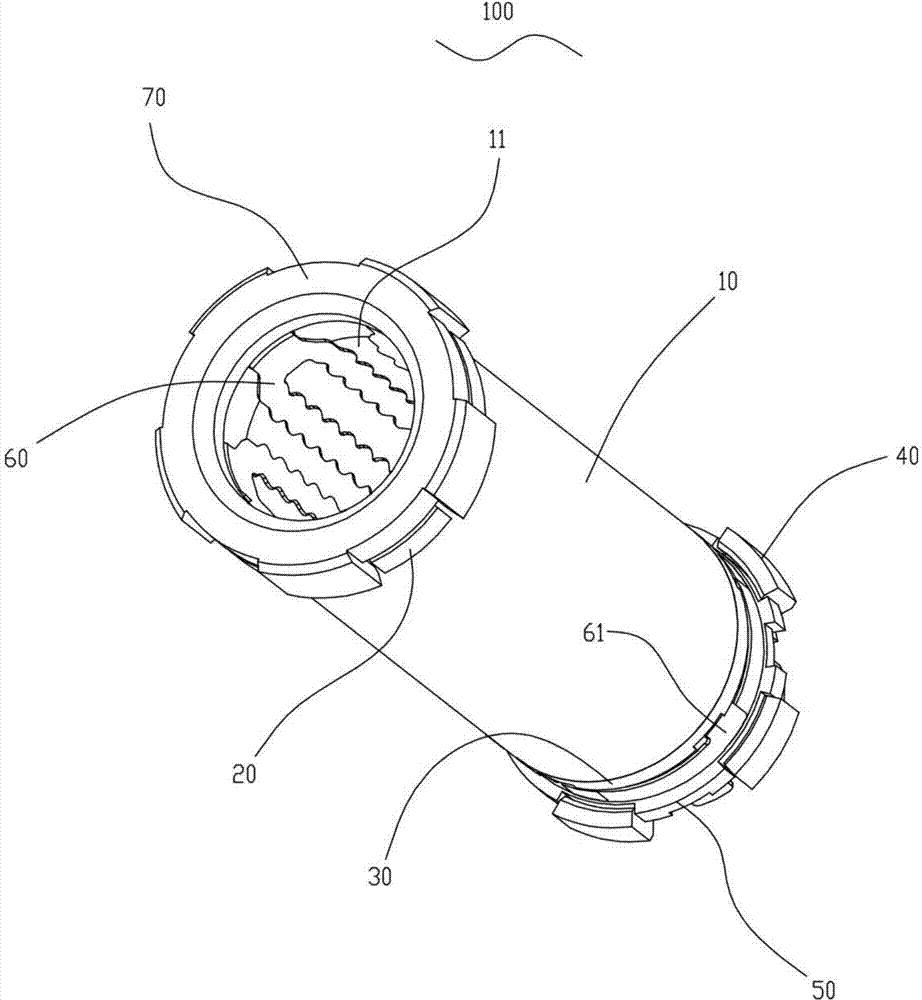

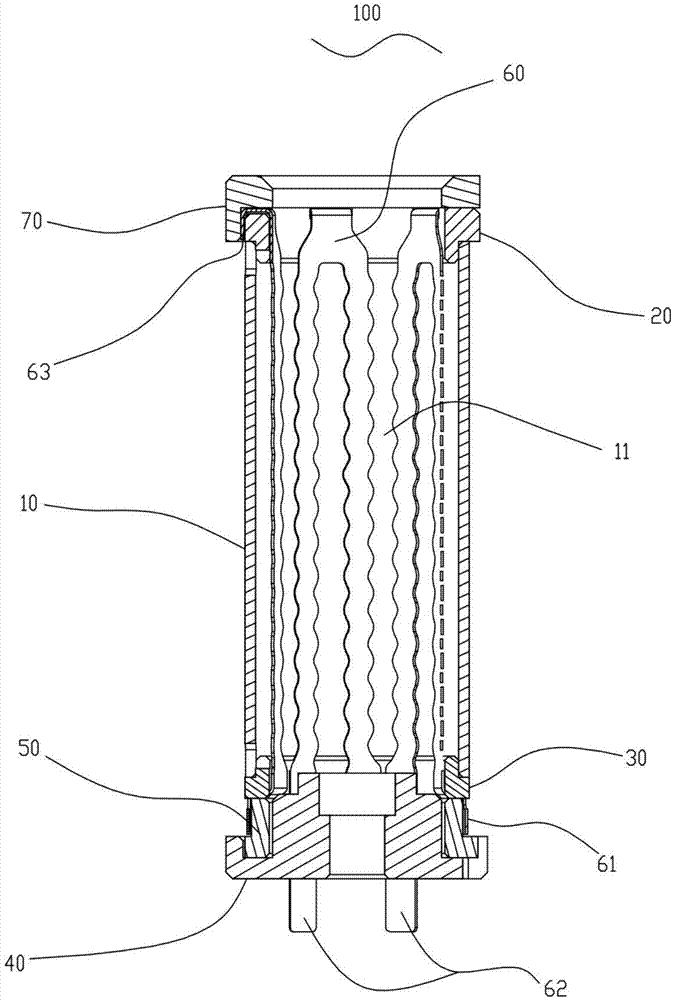

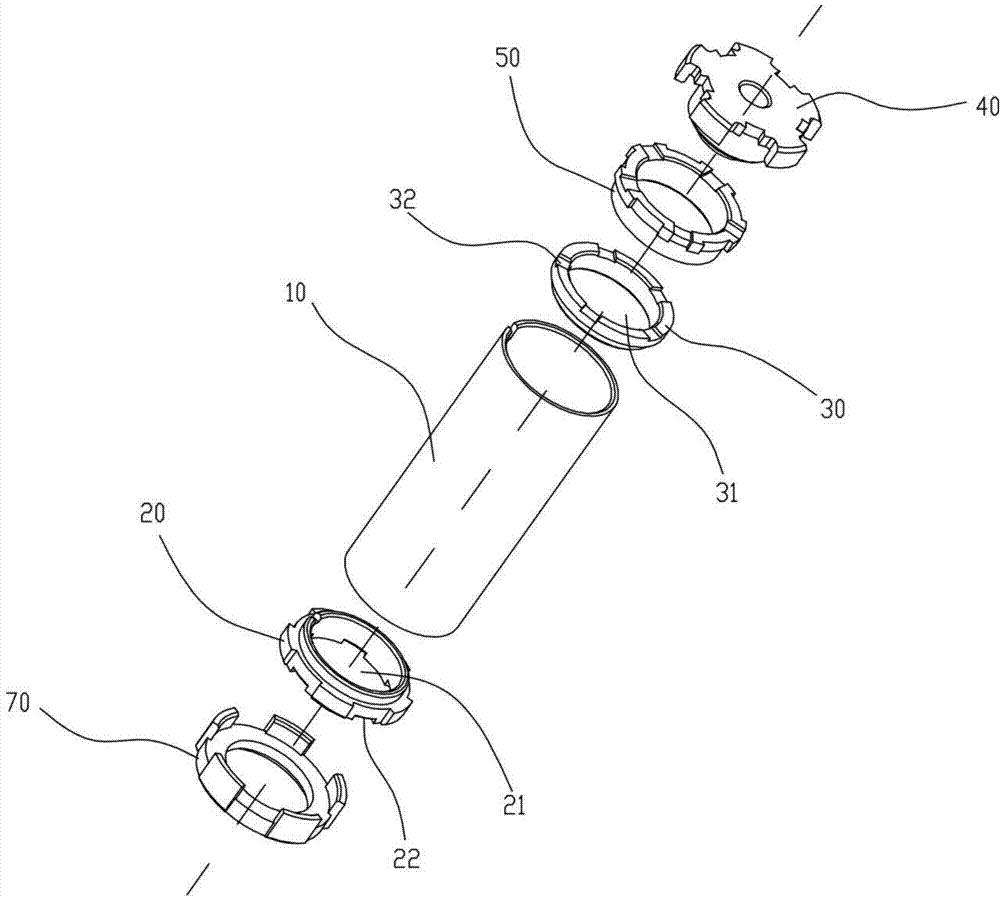

[0044] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses a smoke generator 100 for combining with a power supply 200 to form a smoke suction device (such as Figure 10 ), which includes a support tube 10 made of a heat-resistant material, a plurality of heating elements 60 with a first end 63 and a second end 64 arranged in the support tube, a first bracket 20 with an air outlet 21 and a The second bracket 30 of the air inlet 31, the first bracket 20 and the second bracket 30 are arranged at both ends of the support pipe 10, and the first bracket and the second bracket are all provided with a plurality of positioning parts, and the plurality of the The first ends of the heating elements are all erected on the first bracket and bent on the positioning part of the first bracket, and the second ends are all erected on the second bracket and bent at the positioning part of the second bracket. In part, the heating element 60 surrounds a cavity 11 suita...

Embodiment 2

[0062] Described assembly method comprises the following steps:

[0063] a. Fix the first bracket 20 and the second bracket 30 at both ends of the support tube 10;

[0064] b. Sleeve the support tube 10 obtained in step a on an assembly rod 91 suitable for passing through the support tube 10;

[0065] c. Insert the first end 63 of the heating element 60 along the end of the second bracket 30 from the gap between the support tube 10 and the assembly rod 91 until the first end 63 of the heating element 60 protruding from the end of the first bracket 20;

[0066]d. Bending the two ends of the heating element 60 on the positioning parts of the first bracket 20 and the second bracket 30 respectively, so as to fix the heating element 60;

[0067] e. Fix each heating element 60 on the first bracket 20 and the second bracket 30 along the circumferential direction of the support tube 10 in sequence, so that a plurality of heating elements 60 surround a cavity suitable for filling sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com