Dynamic wave system used for treating combustion flue gas of electronic waste material

A technology for burning flue gas and electronic waste, applied in the field of dynamic wave system, can solve the problems of increasing flue gas discharge resistance, maintenance difficulties, increasing gas-liquid contact time, etc., and achieves a remarkable purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

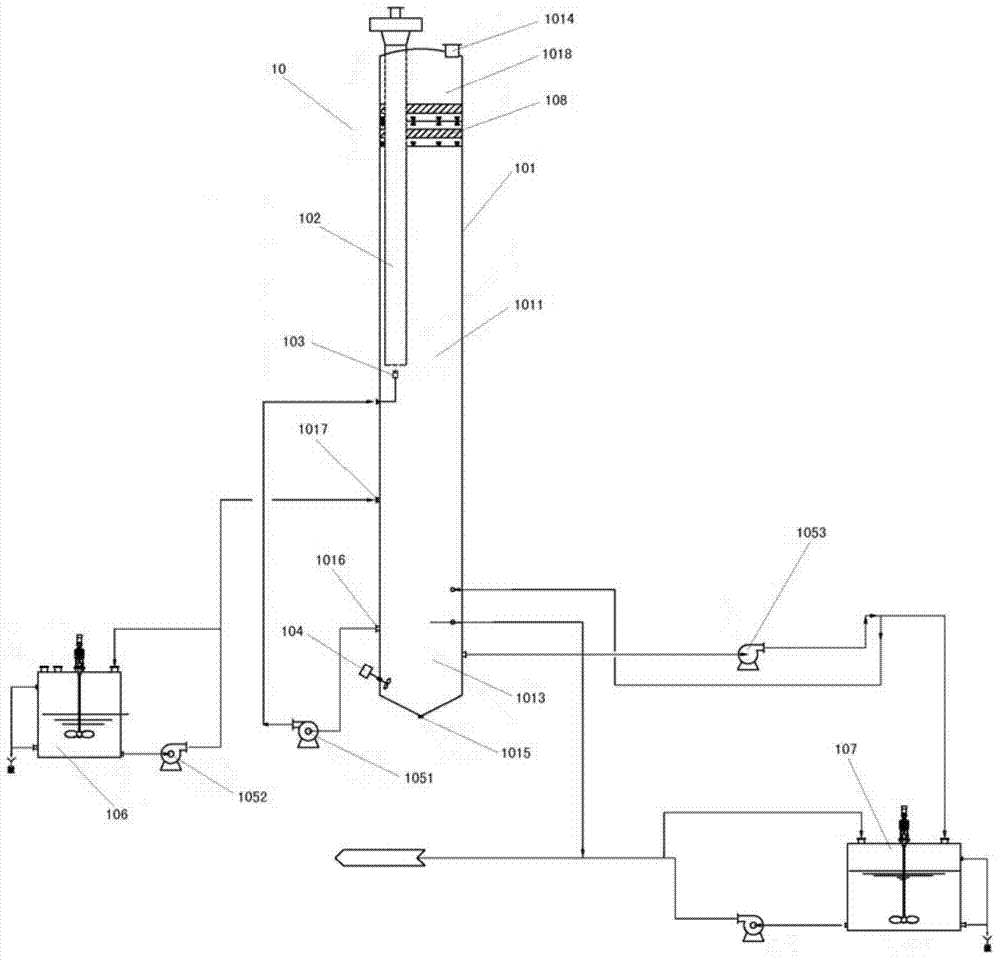

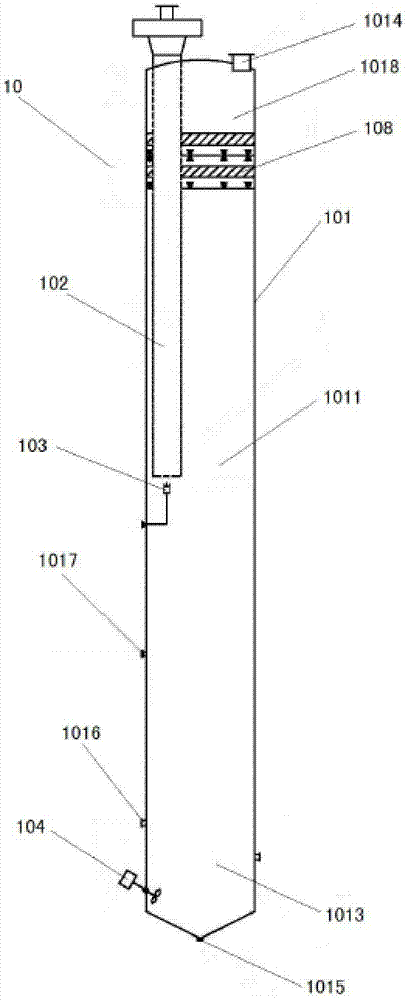

[0020] The following describes a power wave system 10 for treating combustion flue gas of electronic waste according to an embodiment of the present invention with reference to the accompanying drawings. Such as figure 1 and figure 2 As shown, the kinetic wave system 10 for treating electronic waste combustion flue gas according to the embodiment of the present invention includes a reaction tower 101 , a reverse spray pipe 102 and a liquid inlet nozzle 103 for spraying absorption liquid upward.

[0021] There is a gas-liquid separation section 1011 inside the reaction tower 101 , and a purified flue gas outlet 1014 communicating with the gas-liquid separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com