Guide apparatus of medium speed coal mill vane throat ring

A diversion device and coal grinding technology, which is applied in the field of mechanical components, can solve the problems of reducing the discharge rate of pebble coal, and achieve the effects of reducing the discharge rate, increasing the wind speed, and improving the pulverizing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

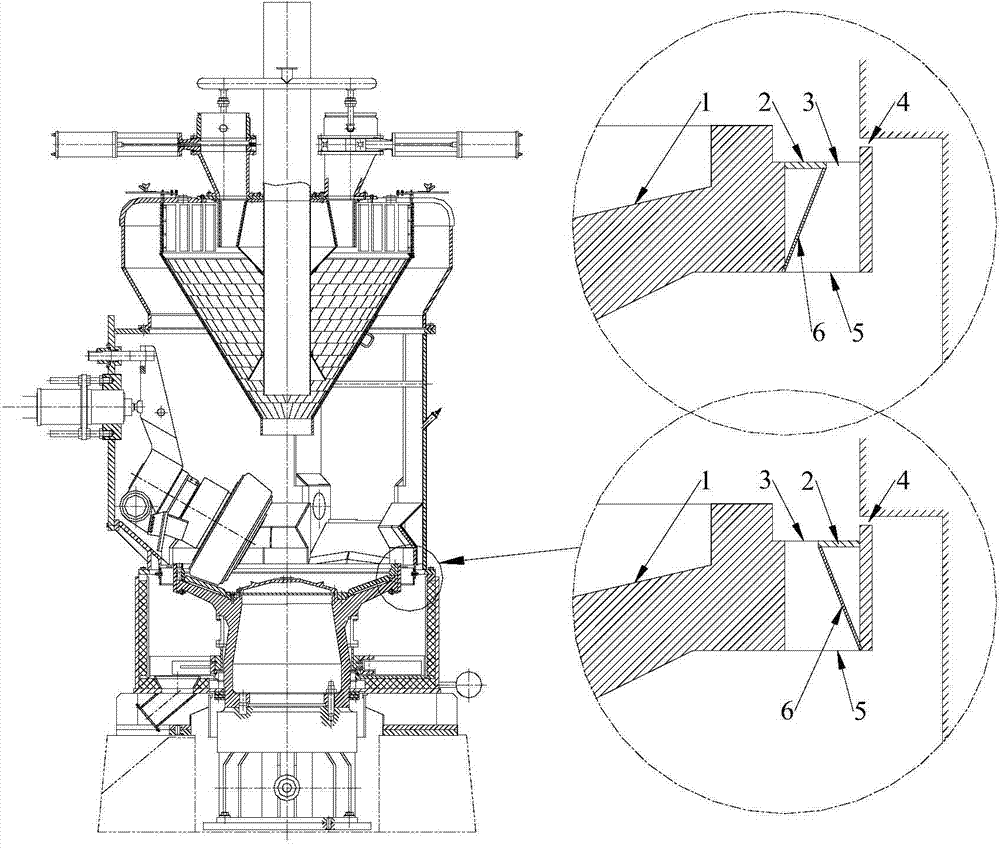

[0018] Such as figure 1 with figure 2 As shown, the deflector device of the medium-speed pulverizer air ring flow guide includes a deflector 6 .

[0019] A deflector 6 is added to the lower part of the existing coal mill wind ring flow ring 2 .

[0020] The upper end of the deflector 6 is fixed on the edge of the throttle ring 2 near the outlet 3 of the air ring, and the lower end is fixed on the edge of the inlet 5 of the air ring near the primary air chamber.

[0021] In order to better cooperate with the wind ring, the deflector 6 has the same upper end with the same circular arc as the wall at the throttle ring 2, and the same lower end with the same circular arc with the wall at the air ring inlet 5.

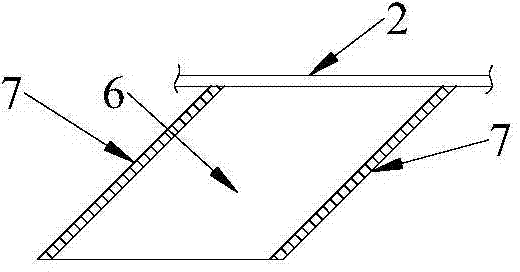

[0022] Such as figure 2 As shown, in order to cooperate with the swirl vanes 7 in the wind ring, the two sides of the deflector 6 should be inclined, and the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com