A fully automatic betel nut equal slicer

A fully automatic and slicing machine technology, applied in sorting, metal processing, etc., can solve the problems of difficult health control, cutting betel nuts into waste products, and high management costs, so as to improve production efficiency and hygienic quality requirements, and reduce production Cost, the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

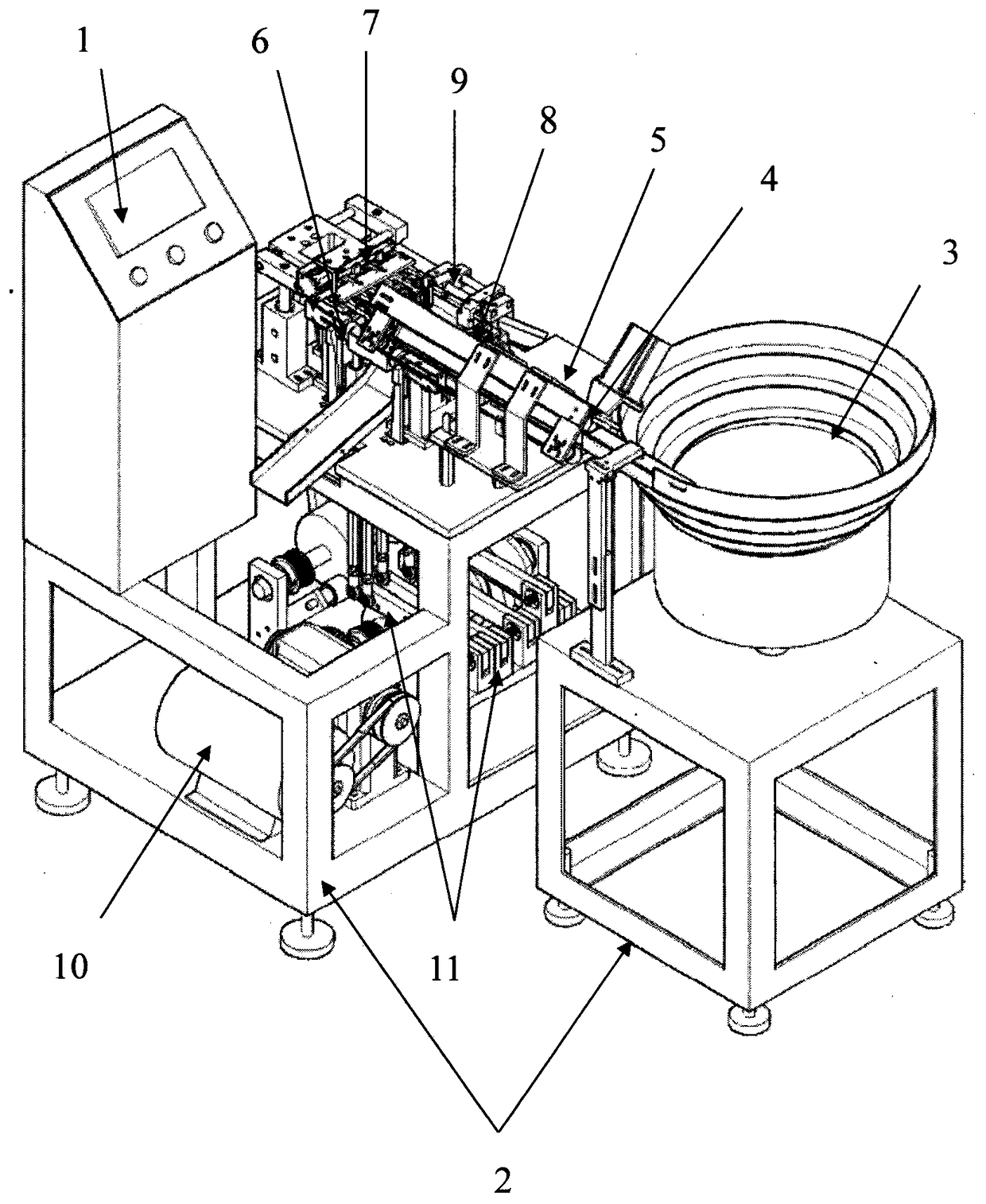

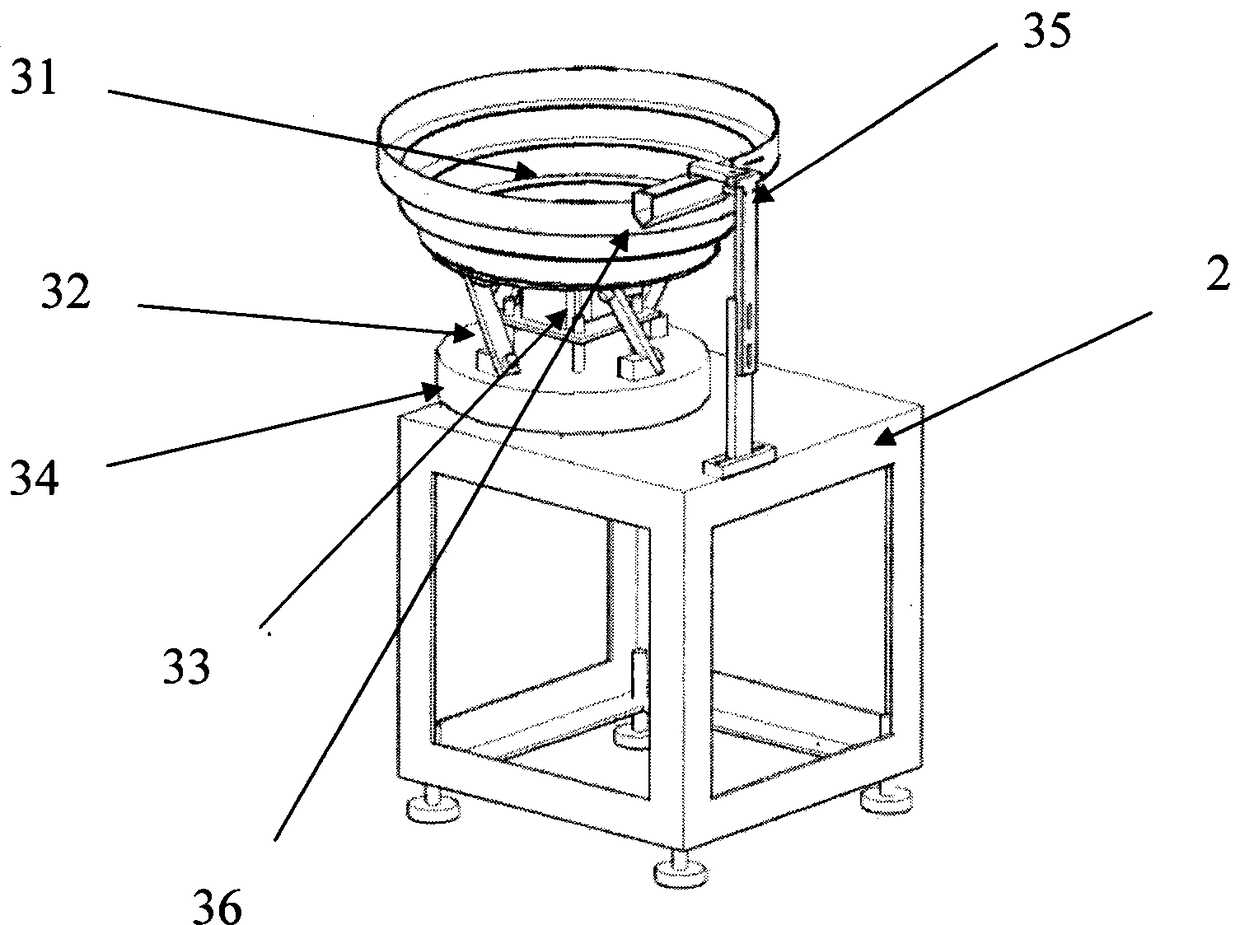

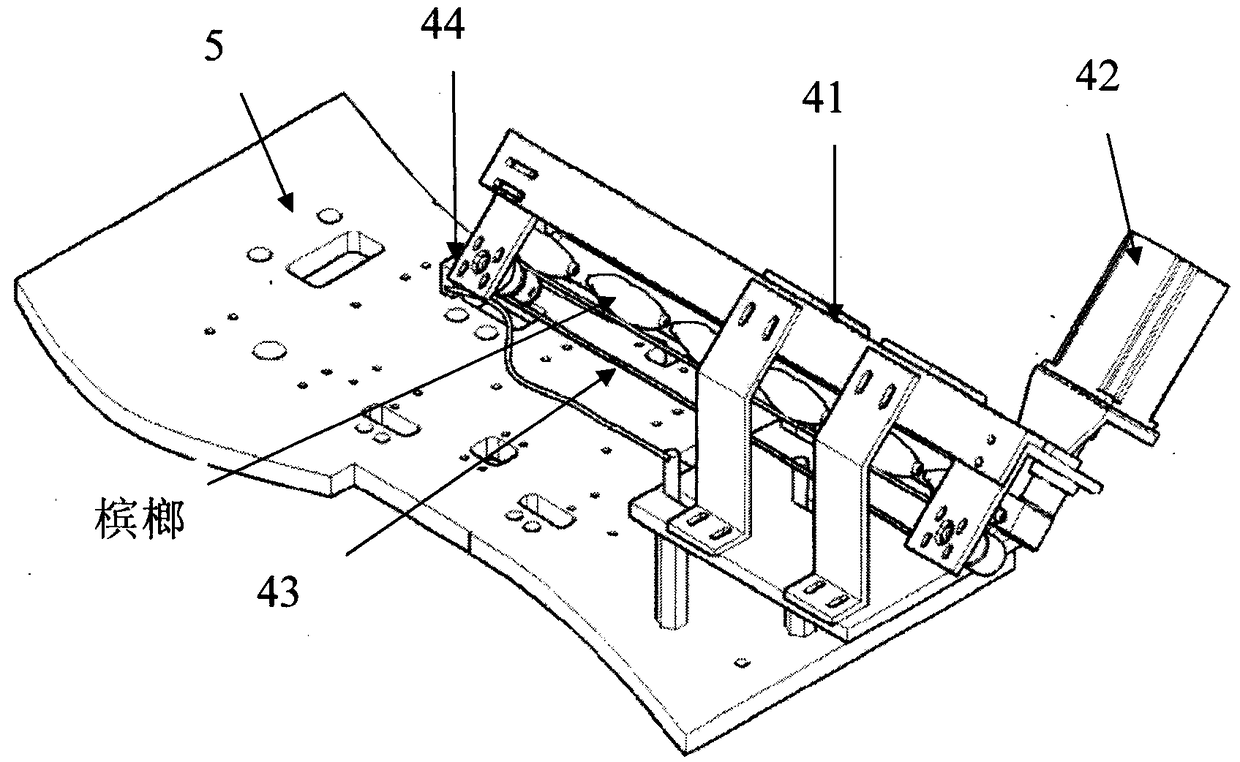

[0031] refer to figure 1 Shown, a kind of full-automatic betel nut equally slicer is characterized in that, mainly comprises two frame assemblies 2 and is installed on the frame assembly and a brake mechanism 10, a transmission mechanism 11, a vibrating row that are arranged and installed successively Material mechanism 3, a transmission mechanism 4, a panel assembly 5, a preliminary positioning mechanism 6, an upper clamp transfer mechanism 7, a lower clamp positioning mechanism 8, a cutting mechanism 9 and a PLC control system 1; The brake mechanism 10, the transmission mechanism 11, the vibrating discharge mechanism 3, the transmission mechanism 4, the preliminary positioning mechanism 6, the upper clamp transfer mechanism 7, and the lower clamp positioning mechanism 8 are respectively connected to the PLC control system 1 circuit; the preliminary positioning mechanism 6. The upper clamp transfer mechanism 7, the lower clamp positioning mechanism 8 and the cutting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com