Injection molding mechanical arm mold anomaly detection method based on LMDO (Local Multilayered Difference Operator)

An anomaly detection and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of poor robustness to light changes and insufficient real-time performance, and achieve the effects of simple implementation, enhanced real-time performance and robustness, and solution to system false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

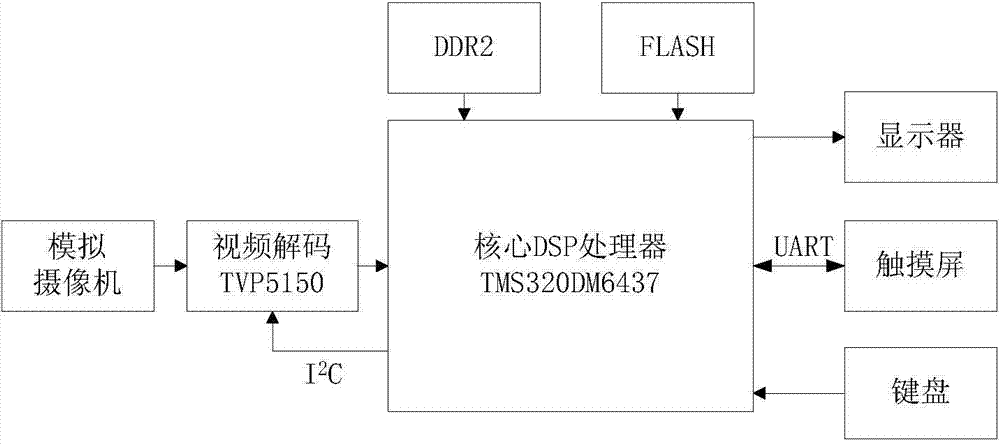

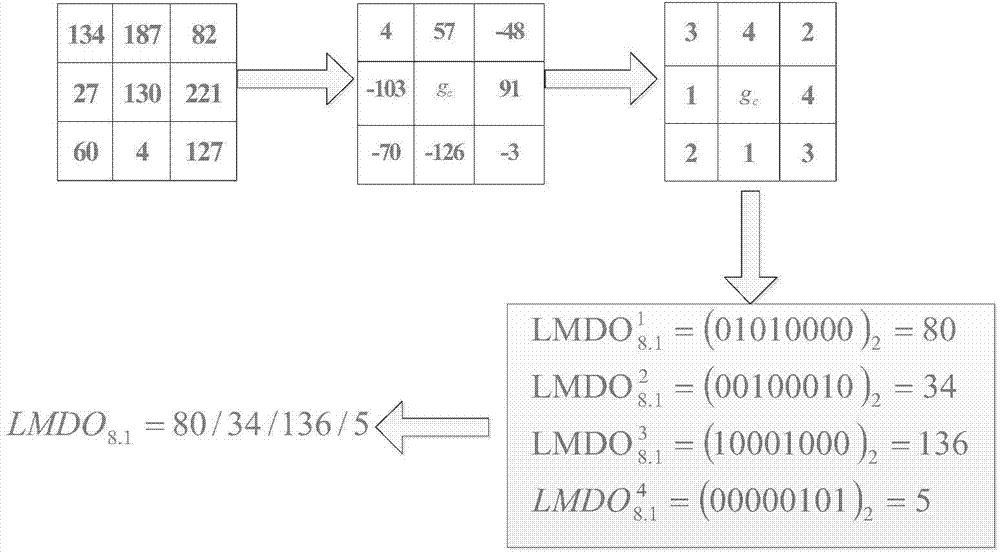

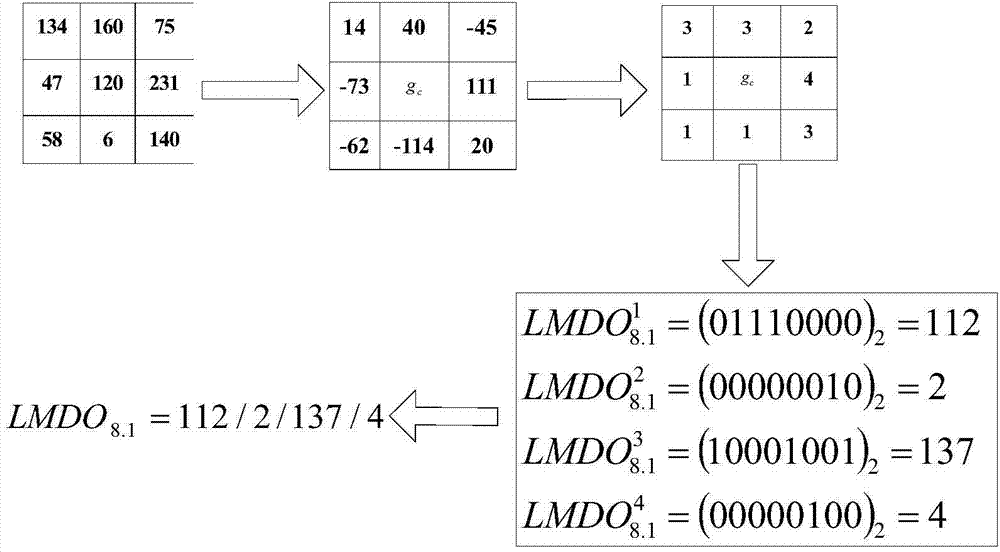

[0036] refer to Figure 1 to Figure 6 , a kind of injection molding manipulator mold anomaly detection method based on LMDO, described anomaly detection method comprises following process:

[0037] 1) Collect the standard template image when the injection molding machine is in place, and perform preprocessing as the subsequent differential background image;

[0038] 2) Wait for the working status information of the injection molding machine. When it is detected that the injection molding machine is running to the mold opening position, the camera continuously captures images of the cavity surface of the mold, extracts the average image of several images, and preprocesses the average image. Prepare for subsequent image processing as the subsequent difference foreground image;

[0039] 3) Execute the LMDO-based anomaly detection algorithm on the difference foreground i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com