Preparation method of low-molecular-plasticizer-free nontoxic soft PVC (polyvinyl chloride) composite

A technology of plasticizer and compound, applied in the field of preparation of soft PVC compound, can solve problems such as poor compatibility and environmental pollution, and achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0043] (1) Preparation of polyacrylate seed latex

[0044] Add 300.0ml deionized water, 1.0g emulsifier SDS to the four-necked reaction flask equipped with reflux condenser, stirring, thermometer and nitrogen inlet, pass nitrogen at room temperature and stir for 0.5 hours, then start the water bath to heat up, when the system temperature A blend of 38.0 g of seed monomer butyl acrylate (BA) and 2.0 g of 2-ethylhexyl acrylate (EHA) and 0.5 g of cross-linking agent BDDA were added to reach 40°C. When the system temperature reached 65° C., 0.6 g of initiator potassium persulfate was added. At the beginning of the reaction, the system exothermicly increased in temperature. When the temperature of the reaction solution was constant to 70°C, the reaction was kept for 1.5 hours. After the heat preservation finishes, add emulsifier SDS 1.0g, add dropwise the mixed solution (95.0g BA, 5.0g EHA, 1.2gBDDA) of the core layer monomer and the core layer cross-linking agent in the system a...

Embodiment example 2-5

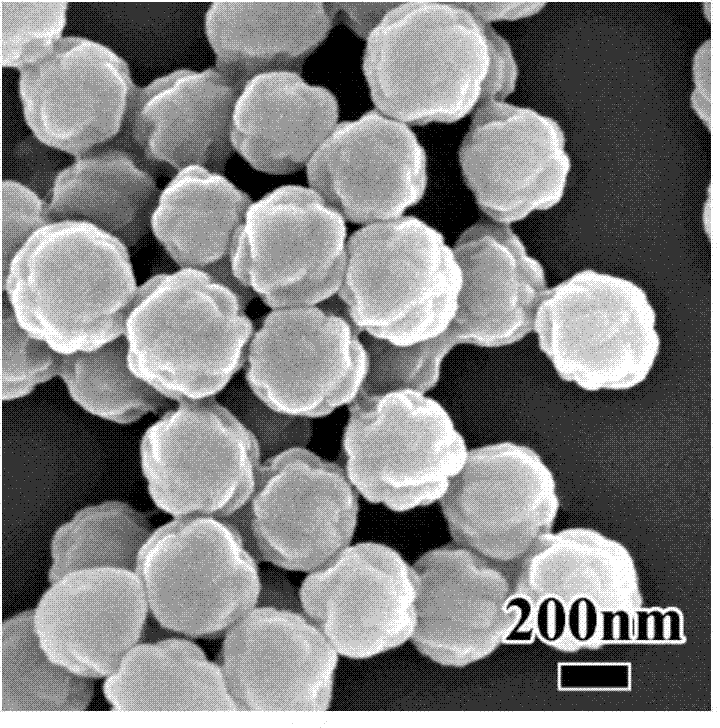

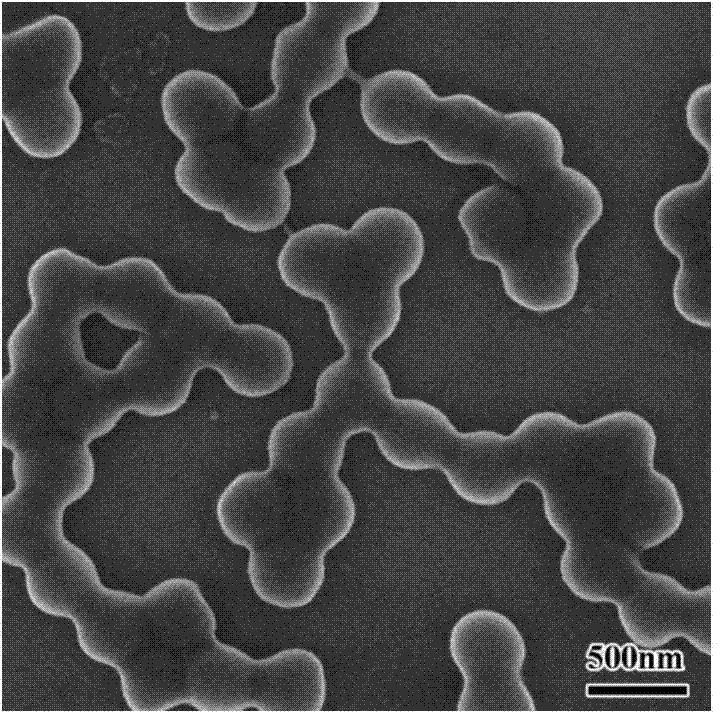

[0057] Change the add-on of methylvinyldiethoxysilane in step (2) to be 0.25g, 0.4g, 0.6g, 0.75g, and all the other implementation processes are the same as implementation case 1, the PVC particles prepared by implementation case 2-5 The SEM photos of the morphology are attached Figure 4-7 .

[0058] attached by figure 1 , 4 , 5, 6, 7 It can be seen that with the increase of the amount of methylvinyldiethoxysilane added, the flower structure on the surface of PVC particles gradually becomes more obvious, and the particles gradually become more uniform.

Embodiment example 6

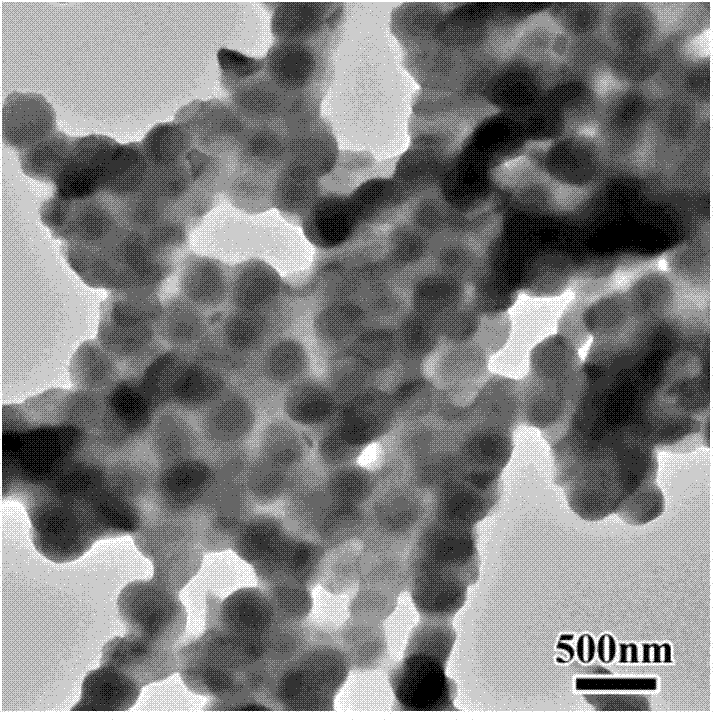

[0060] Change the BA addition in the implementation case 1 step (3) to 7.5g, and all the other implementation processes are the same as the implementation case 1. The SEM photo of the prepared PBA / PVC-sg-PBA composite particles is shown in the attached Figure 8 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap