Recording method and ink set

A recording method and ink technology, applied in the direction of copying/marking method, ink, application, etc., can solve the problems of color ink bleeding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

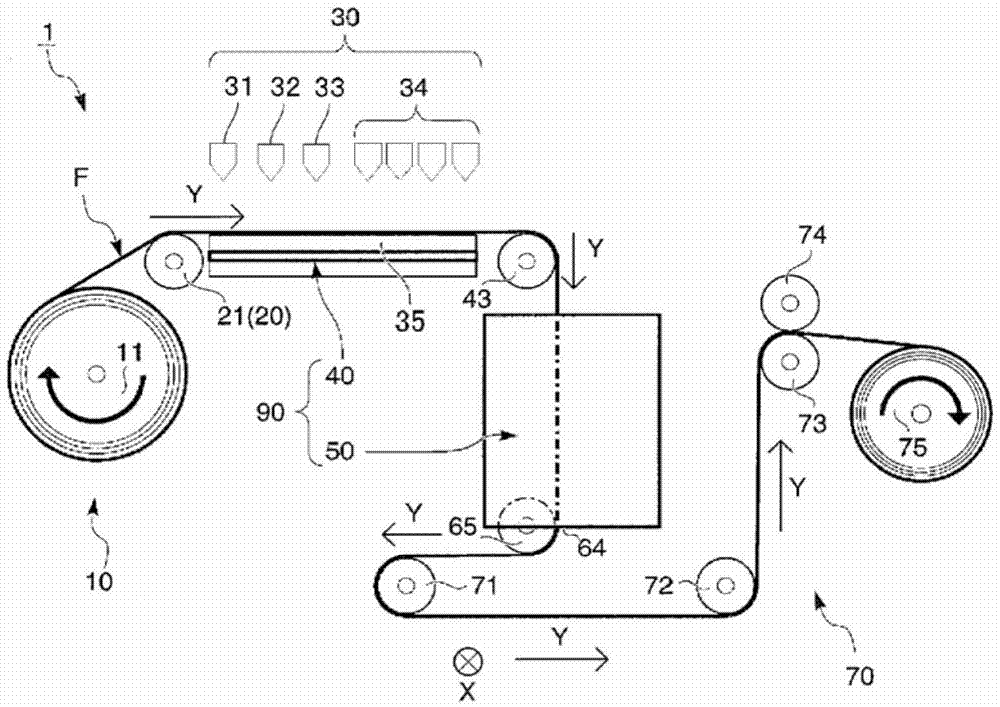

Image

Examples

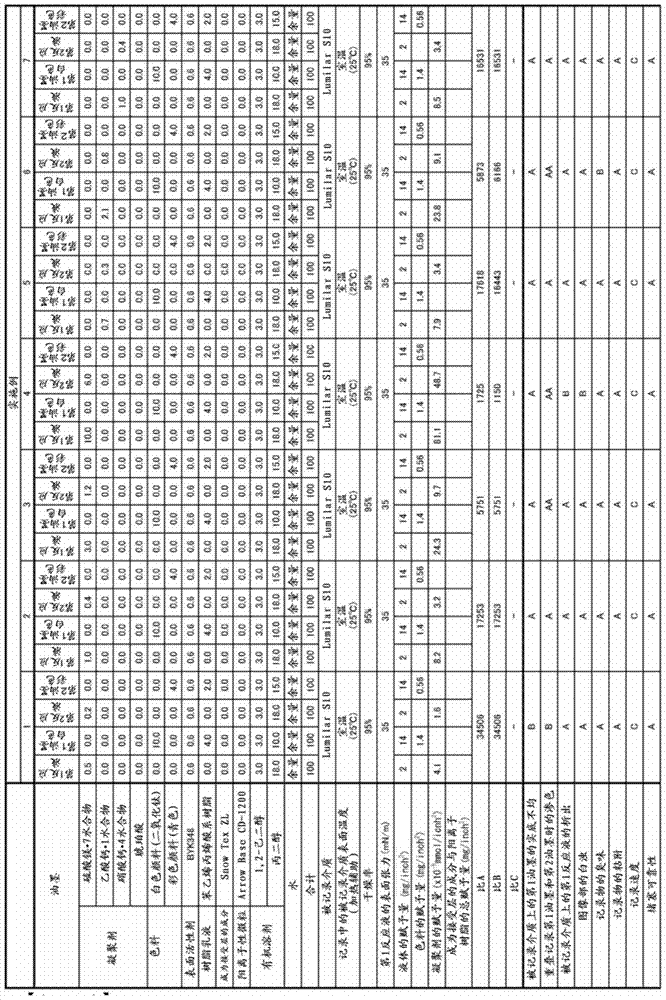

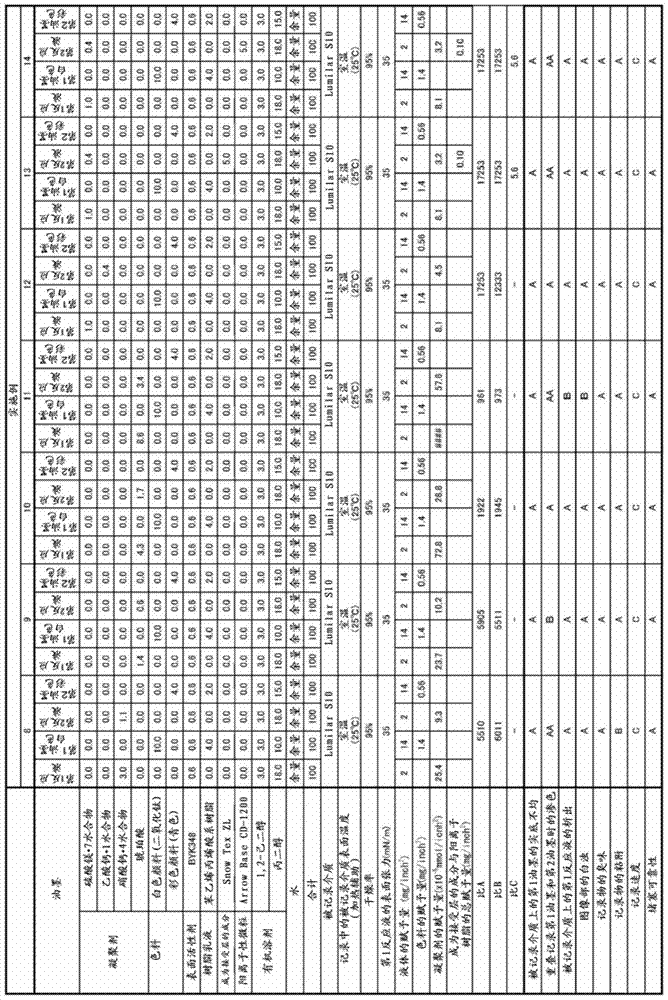

Embodiment 1~20、 comparative example 1~6

[0188] A modified machine using PX-G930 (manufactured by Epson Corporation). The improvement point is that a heater is installed on the pressing plate, which can heat the recording medium. Nozzle spacing is 180dpi. According to the recording conditions shown in Tables 1 to 4, the first reaction liquid, the first ink, the second reaction liquid and the second ink are sequentially ejected from each nozzle by the inkjet method, and respectively adhered to the non-absorbing recording medium made by Toray. A solid ground pattern was formed on PET film "Lumilar S10" (trade name, thickness 100 μm) or NP coated paper (manufactured by Lintec) which is a low non-absorptive recording medium. At this time, pattern 1 obtained by attaching only the first reaction liquid, pattern 2 obtained by overlapping the first reaction liquid and the first ink, and pattern 2 obtained by overlapping the first reaction liquid, the first ink, and the second reaction liquid were formed. pattern 3, and pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com