Cooled Stator Thermal Barrier

A technology of thermal barrier layer and stator, which is applied in the direction of stator, engine manufacturing, machine/engine, etc., can solve the problems of impossible leading edge area, too large, etc., and achieve the effect of saving coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

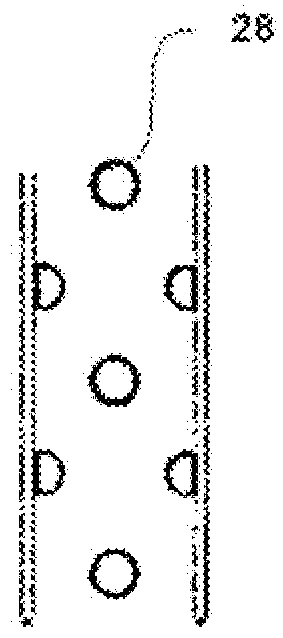

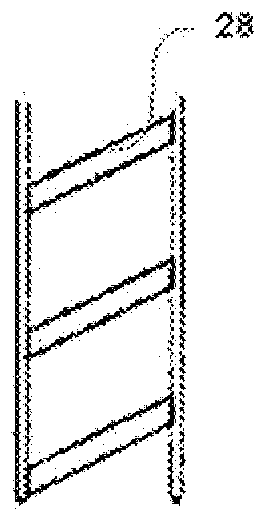

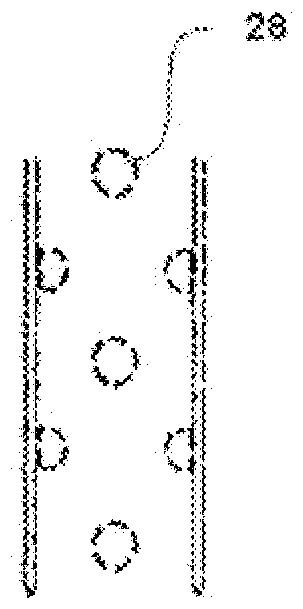

[0052] according to figure 1 , a gas turbine 1 of which only small details are shown here, has a stator 2 and a rotor 3 , each of which is also only partially shown. Sections of the vanes 4 of the stator 2 and of the vane carrier 5 are discernible. The vane 4 is attached to a vane carrier 5 . The stator thermal barrier layer 10 is mounted on the vane carrier 5 . Only one turbine blade 6 of the rotor 3 can be discerned here, which blade is arranged between the two guide vanes 4 . The axis of rotation 9 , around which the rotor 3 rotates during operation of the gas turbine 1 and which defines the axial direction of the gas turbine 1 , is indicated here in dashed lines. Axial in this context therefore means parallel to the axis of rotation 9 , whereas the radial direction is perpendicular to the axis of rotation 9 and the circumferential direction is oriented around the axis of rotation 9 along a circular passage. Thus, the rotor blade 6 is arranged axially between the two gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com