Preparation method and positioning method for transmission electron microscope sample

A sample and lens technology, applied in the field of transmission electron microscope sample preparation, can solve problems such as poor judgment and inability to guarantee the success rate of sample preparation, and achieve the effect of simple positioning method, low cost, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose and features of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

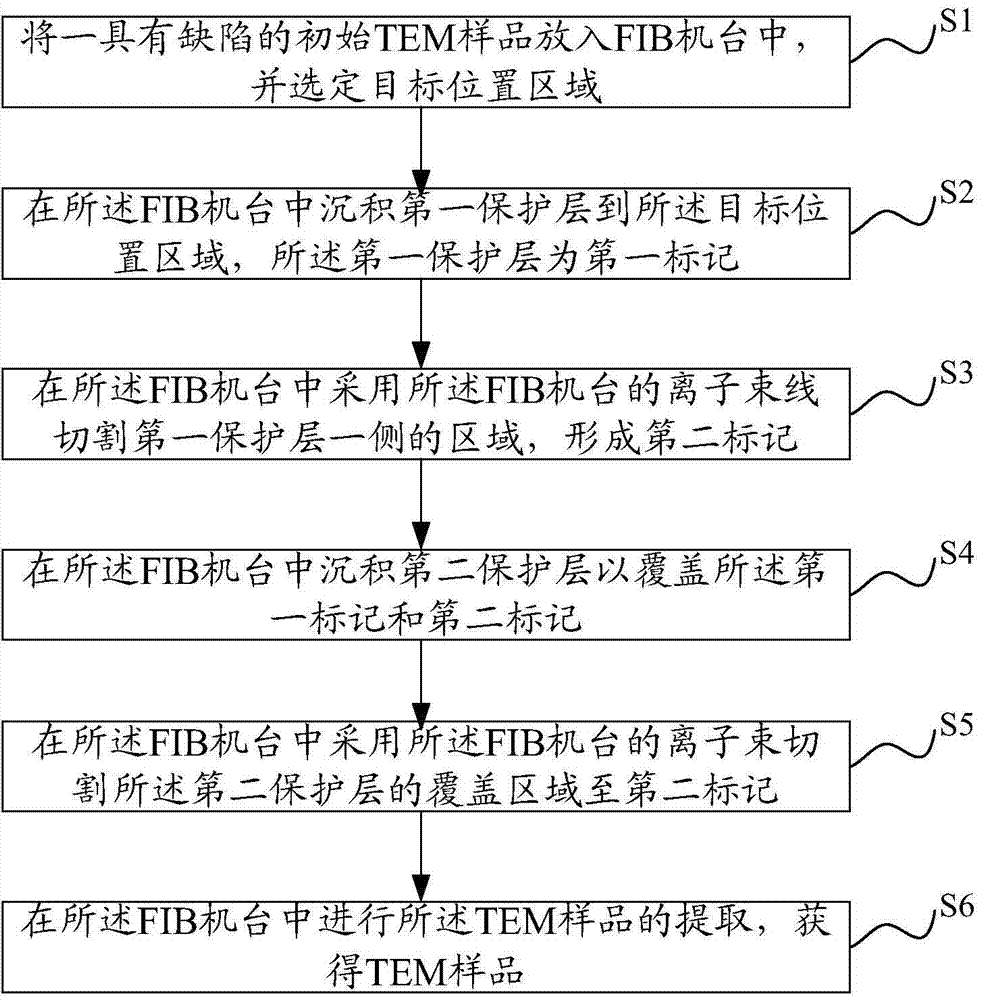

[0035] Please refer to image 3 , the present invention proposes a positioning method of a lens sample, comprising:

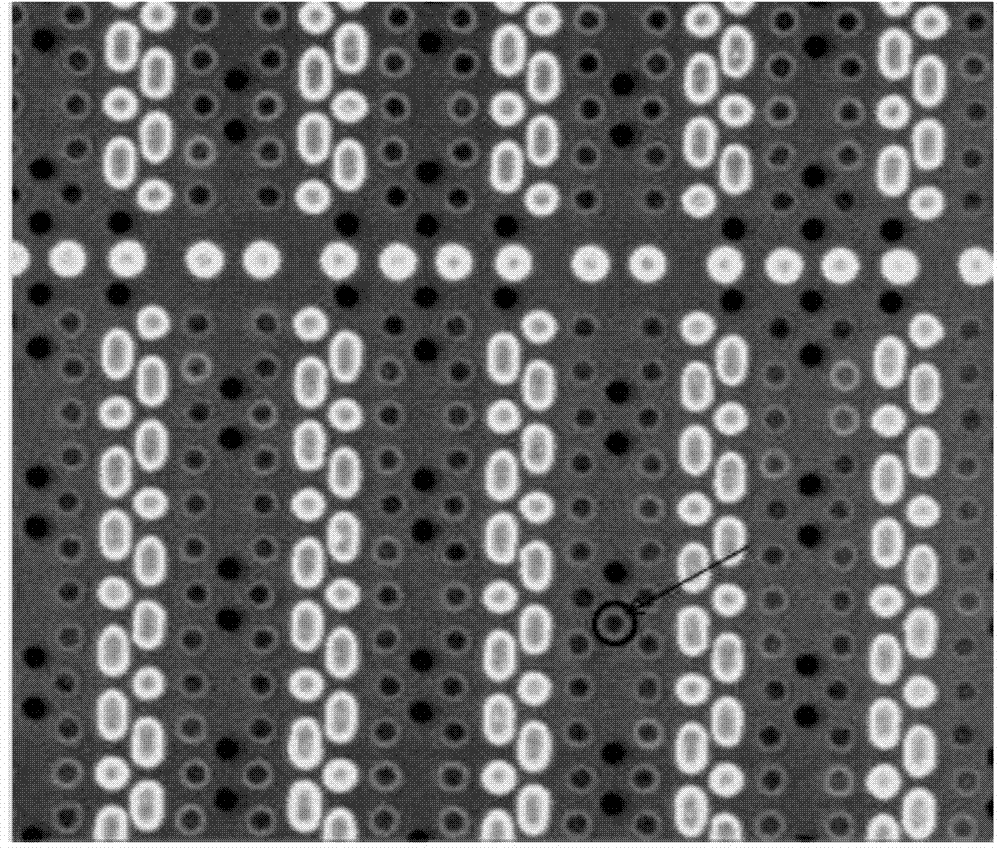

[0036] S1, put an initial TEM sample with defects into the FIB machine, and select the target location area;

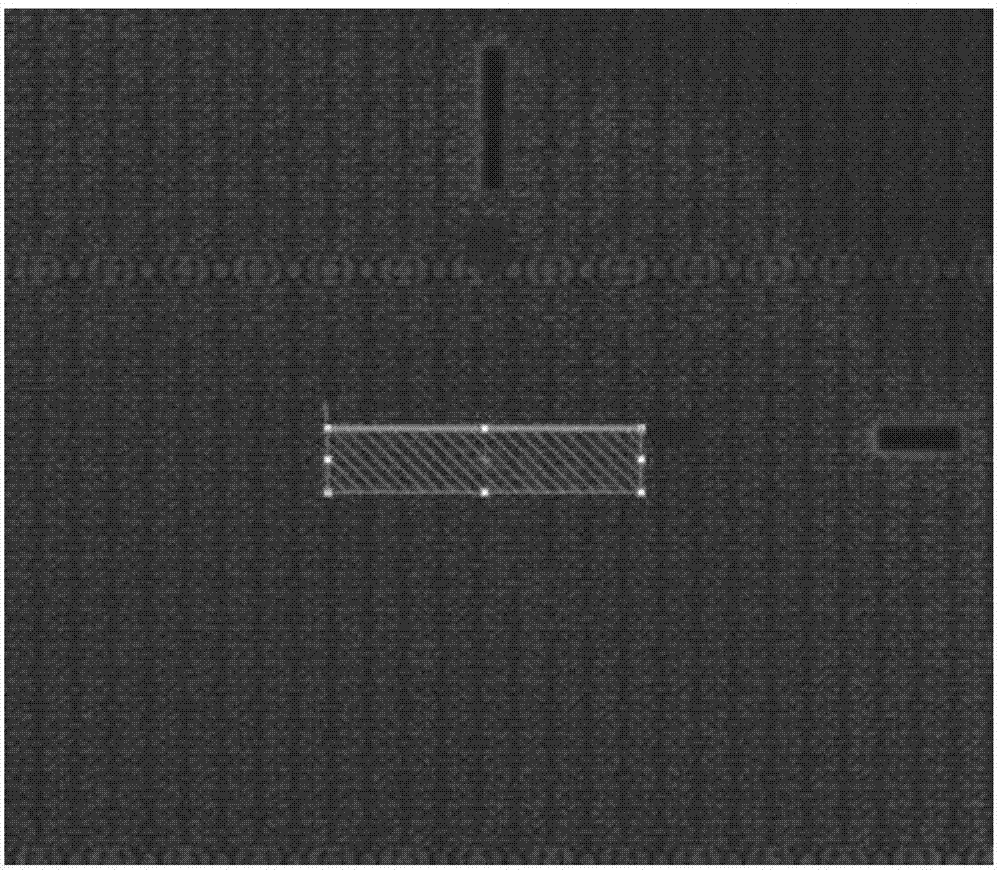

[0037] S2. Depositing a first protective layer on the target position area in the FIB machine, where the first protective layer is a first mark;

[0038] S3, using the ion beam line of the FIB machine to cut an area on one side of the first protective layer in the FIB machine to form a second mark;

[0039] S4, depositing a second protective layer in the FIB machine to cover the first mark a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com