Fully-reflective material and preparation method thereof as well as fully-reflective fabric

A reflective material and total reflective technology, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as low economic benefits, inability to achieve total reflective, reflective material detachment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

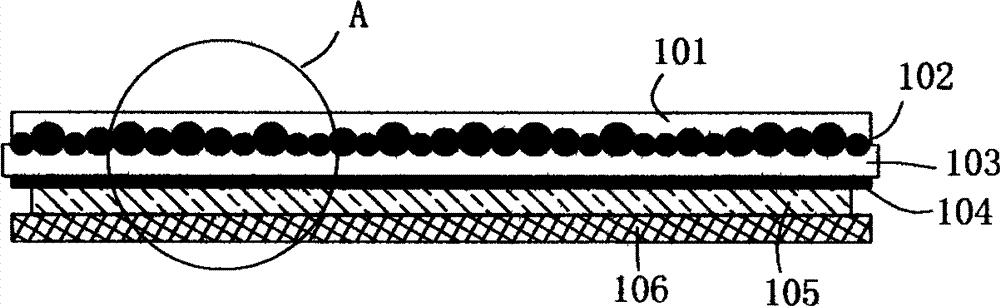

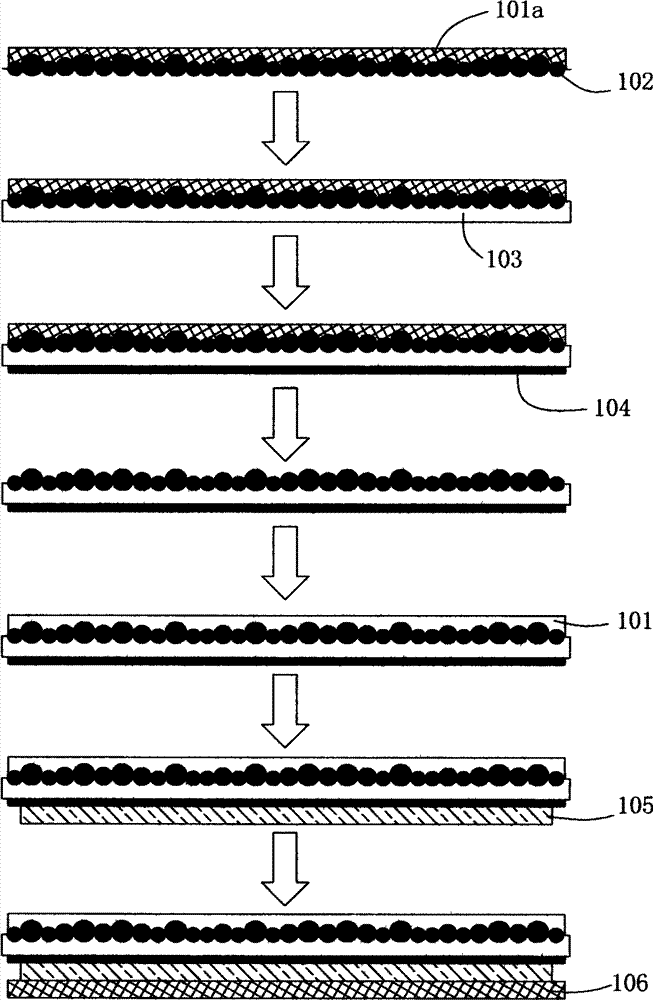

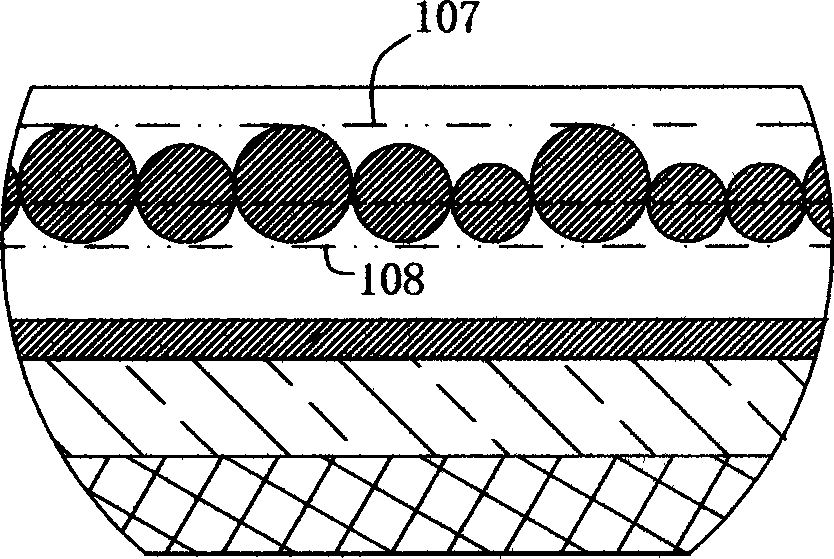

[0033] refer to figure 1 , image 3 , the first embodiment of the present invention is a kind of total reflective cloth, comprising a kind of total reflective material, and this total reflective material comprises glass bead layer 102, also comprises resin layer 103, and described glass bead layer 102 is made of several bonded to resin layer 103 surface, and partially embedded in the glass beads inside the resin layer 103, the glass beads include glass beads with the largest diameter, glass beads with the smallest diameter, and glass beads with diameters between the largest and the smallest; refer again image 3 , in the thickness direction of the total reflective material, the plurality of glass beads are aligned to one side of the resin layer, in image 3 The double-dashed reference line 107 shows the uneven side of the glass bead layer 102, and the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com