A control method for a double-station winder

A dual-station winder and control method technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of low winding efficiency, large waste of funds, etc., and achieve stable double-axis winding, stable operation, and conversion coordination. Roll-up convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

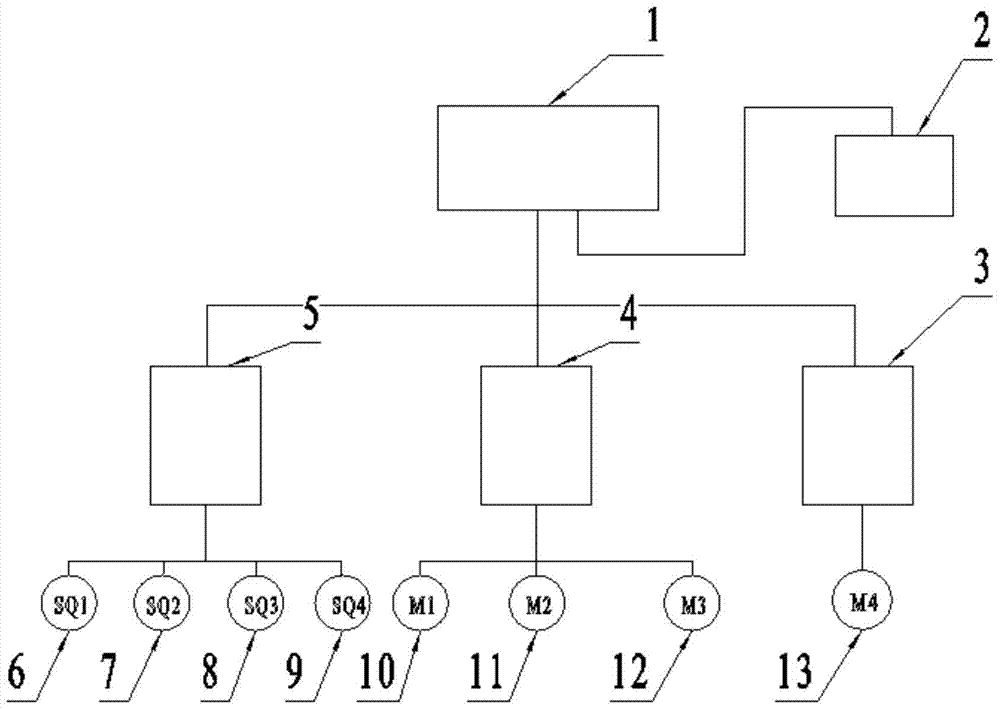

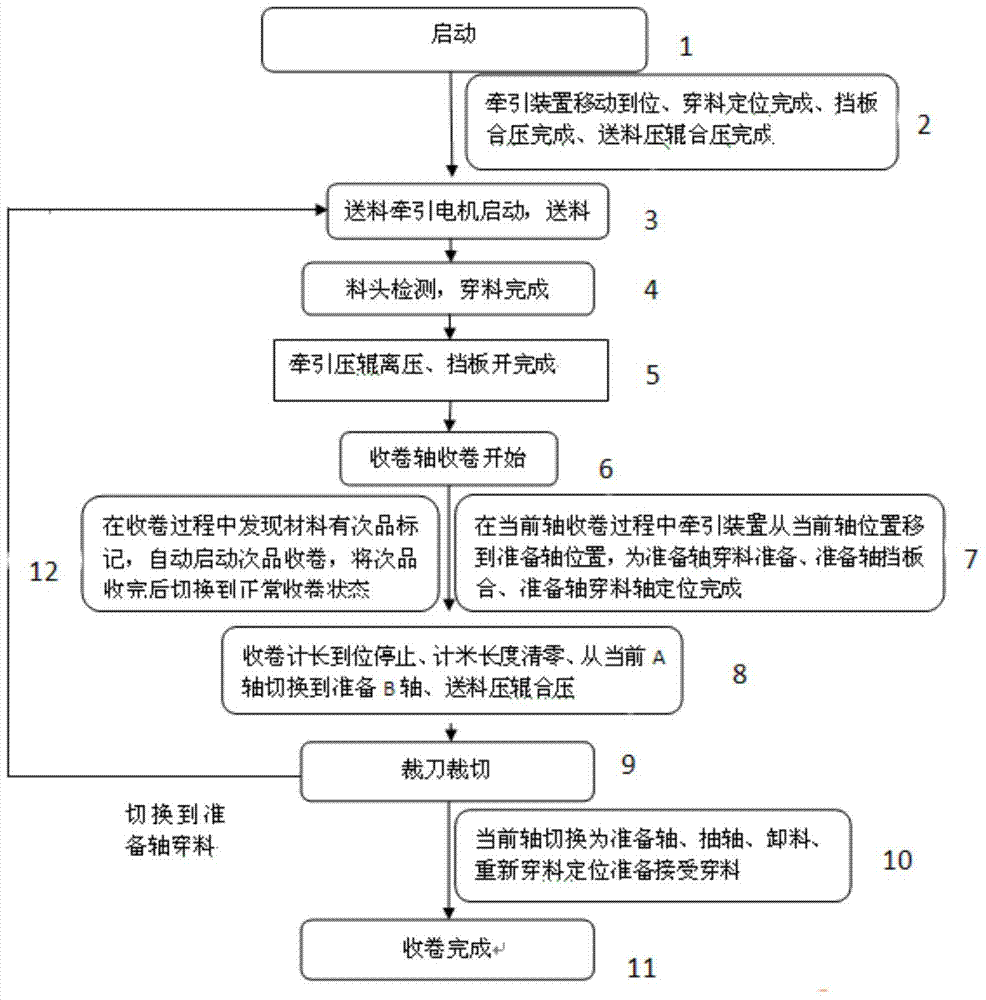

[0021] A double-station winder control method of the present invention is based on a double-station winder control device, such as figure 1 As shown, the structure of the double-station winding machine control device is: including a servo controller 1, the servo controller 1 is respectively connected with a touch screen 2 and a motion control unit 4, and the motion control unit 4 is connected to the A-axis 10 and the B-axis at the same time 11 and the feeding servo motor 12, the servo controller 1 is also connected to the I / O unit 5 and the high-speed counting unit 3, and the I / O unit 5 is connected to the SQ1 photoelectric detection electric eye 6, SQ2 photoelectric detection electric eye 7, SQ3 photoelectric detection electric eye 8, SQ4 photoelectric detection electric eye 9, the high-speed counting unit 3 is connected with the encoder met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com