OLED (organic light emitting display) device

A technology for display devices and pixels, applied in the field of OLED display devices, can solve the problems of deterioration of light-emitting properties of organic light-emitting layers, loss of electric field light-emitting properties, short-circuiting of electrodes, etc., to avoid short-circuiting of cathode and anode, improving display effect, and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

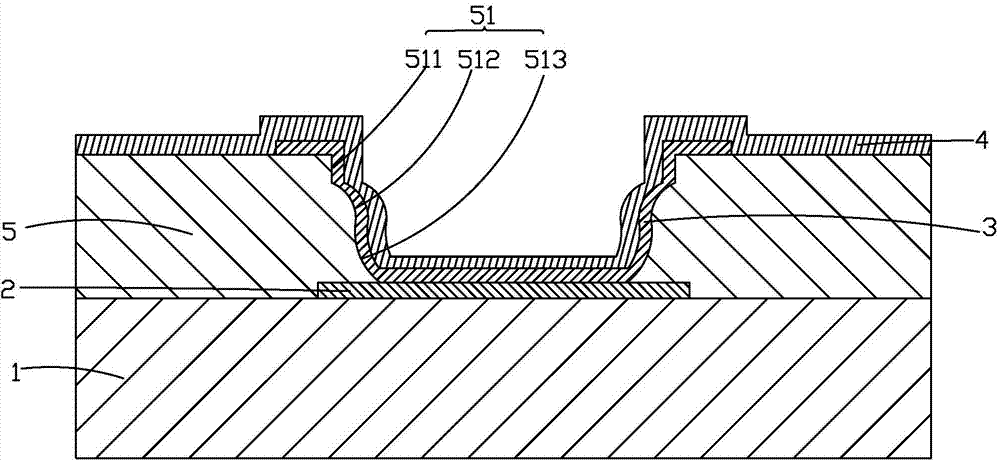

[0029] see figure 1 , the present invention provides an OLED display device, comprising:

[0030] Substrate 1;

[0031] A plurality of pixel areas arranged in an array on the substrate 1, each pixel area includes a pixel electrode 2, an organic light-emitting layer 3, and a common electrode 4 sequentially stacked on the substrate 1;

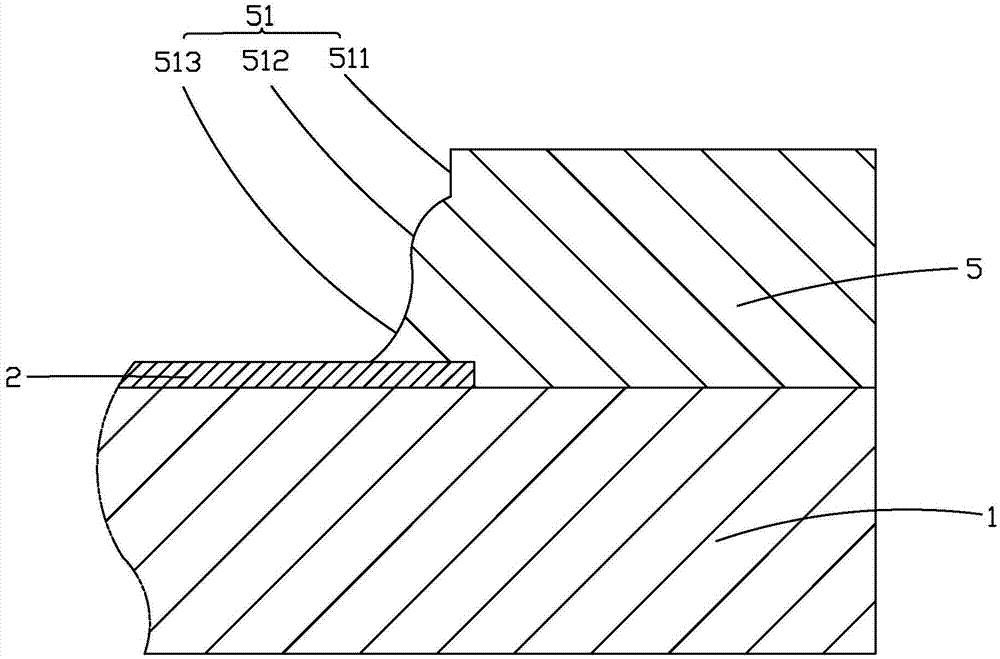

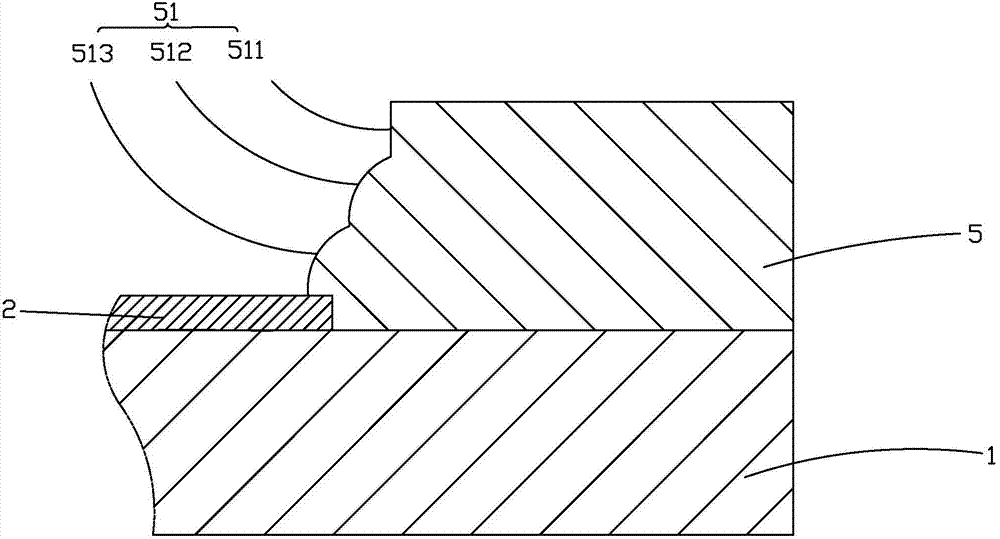

[0032] And a pixel isolation layer 5 with a plurality of openings, the pixel isolation layer 5 isolates each pixel area from other pixel areas, the openings are surrounded by side walls 51 of the pixel isolation layer, and each opening corresponds to a pixel area .

[0033] Wherein, the pixel electrode 2 and the organic light-emitting layer 3 are located in the opening, and the organic light-emitting layer 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com