Manipulator for boxing robot

A manipulator and robot technology, applied in the field of manipulators, can solve the problems of inflexible adjustment control, slow running speed, poor stability, etc., and achieve the effect of efficient and flexible adjustment and control, stable operation and agile action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Although the present invention has been described with reference to specific embodiments, those skilled in the art will be able to make obvious modifications and modifications to the present invention after reading the above description without departing from the intent and essence of the present invention. The present invention intends to include such modifications and modifications within the scope of the claims.

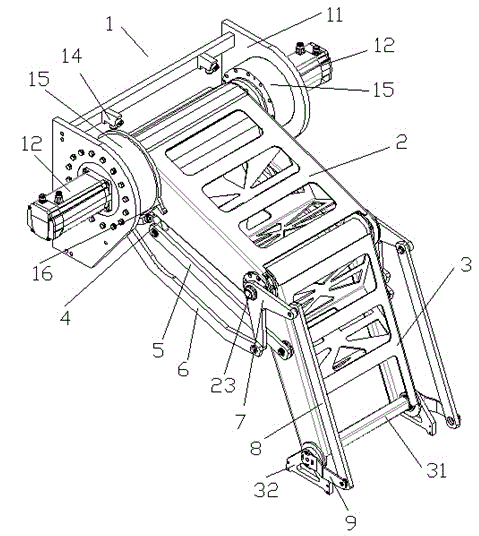

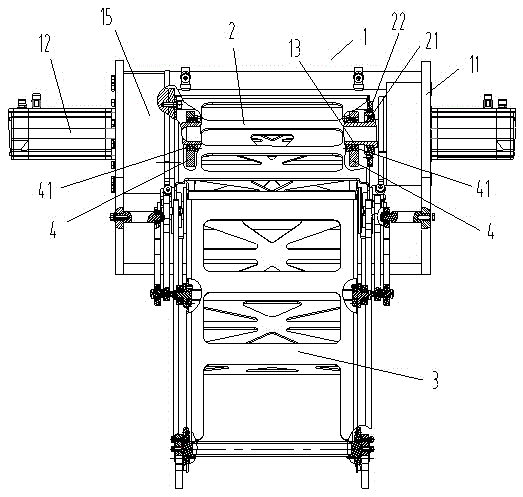

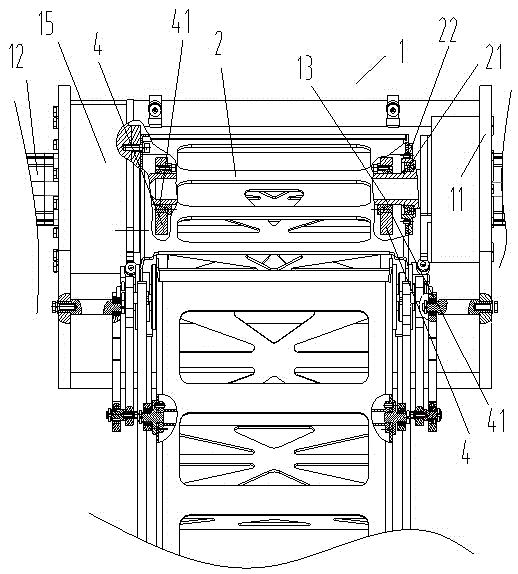

[0026] A manipulator for a box packing robot such as Figure 1 to Figure 5 As shown, it includes a motor assembly 1, a boom 2, a small arm 3, a swing arm 4, a drive rod 5 and a main link 6, and the motor assembly 1 includes a mounting base 11, a motor 12 and a main shaft 13, and the mounting base 11 A limit block 14 is arranged on the rear plate of the base to limit the range of rotation. Motors 12 are respectively installed at both ends of the mounting seat 11. The motors 12 are respectively connected to a reducer 15, and a limit ring is installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com