An inductive micro-current knife breaking detection circuit

A detection circuit and knife breaking technology, applied in the detection field, can solve the problems of low detection sensitivity and high error rate, achieve high detection sensitivity, ensure production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

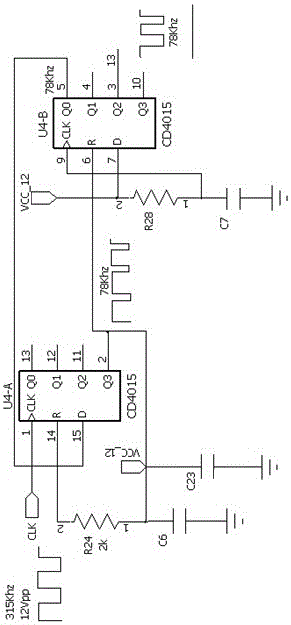

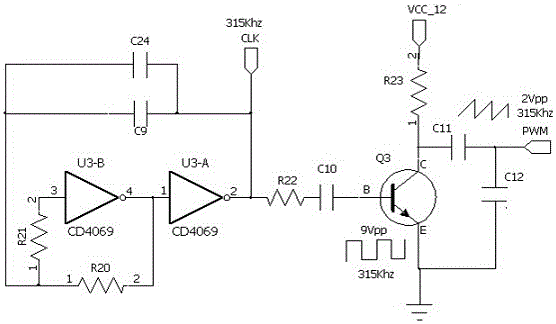

[0018] The circuit of the present invention includes an excitation signal generating circuit, an excitation signal conversion circuit, a signal transmitting circuit, a signal sensing circuit and a signal processing circuit sequentially connected by signals. In addition, it also includes a power supply module for supplying power to each functional module.

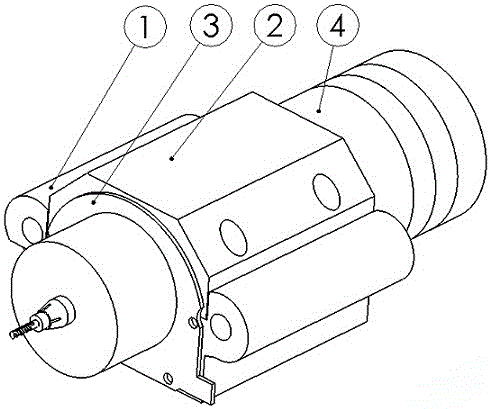

[0019] Among them, the signal transmission circuit and the signal induction circuit adopt magnetic ring coils, and the two sets of coils are sleeved outside the main shaft and fixed on the main shaft base with screws. Such as figure 1 As shown, two groups of coils, one large and one small for transmitting and sensing, form a magnetic ring coil 3, which is set outside the main shaft 4 and fixed on the main shaft seat 1 with screws. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com