Fast drying film device

A film sticking device and fast drying technology, applied in layered products, lamination auxiliary operations, lamination and other directions, can solve the problems of harming the health of operators, affecting the quality of the film, reducing the drying efficiency, etc., and achieving high film quality. , The effect of increasing space utilization and increasing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

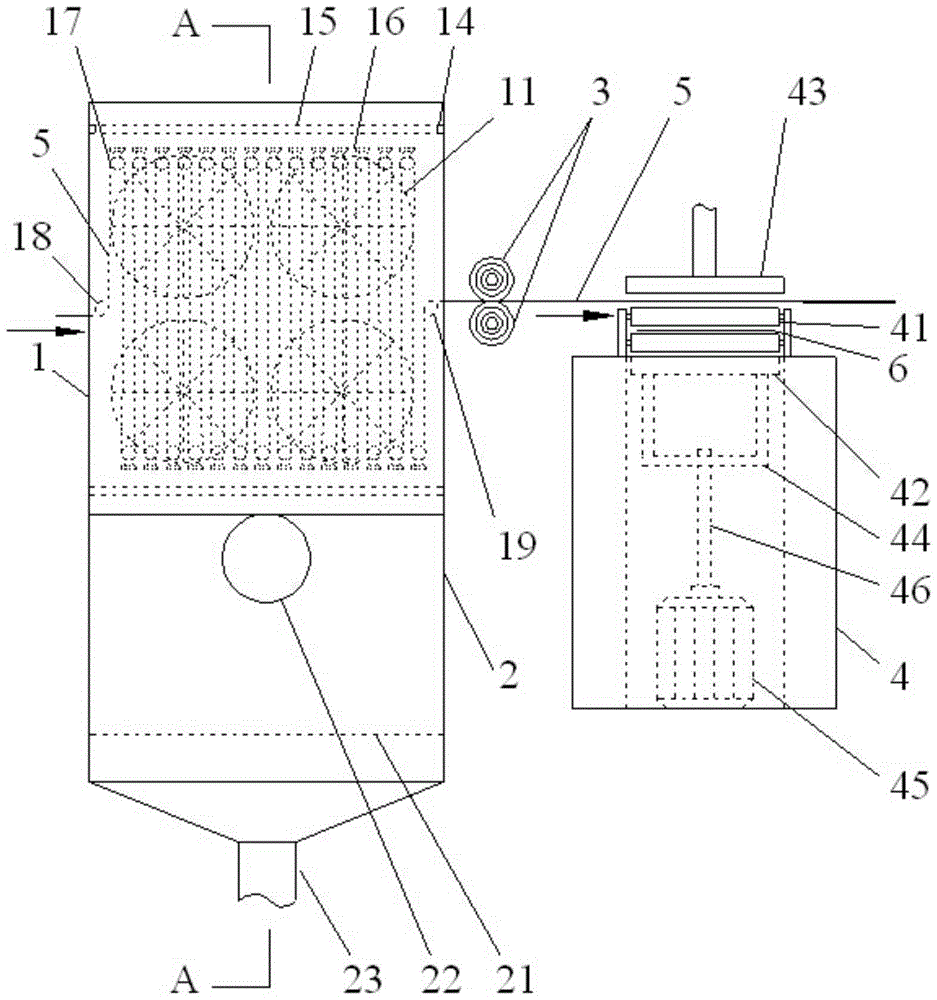

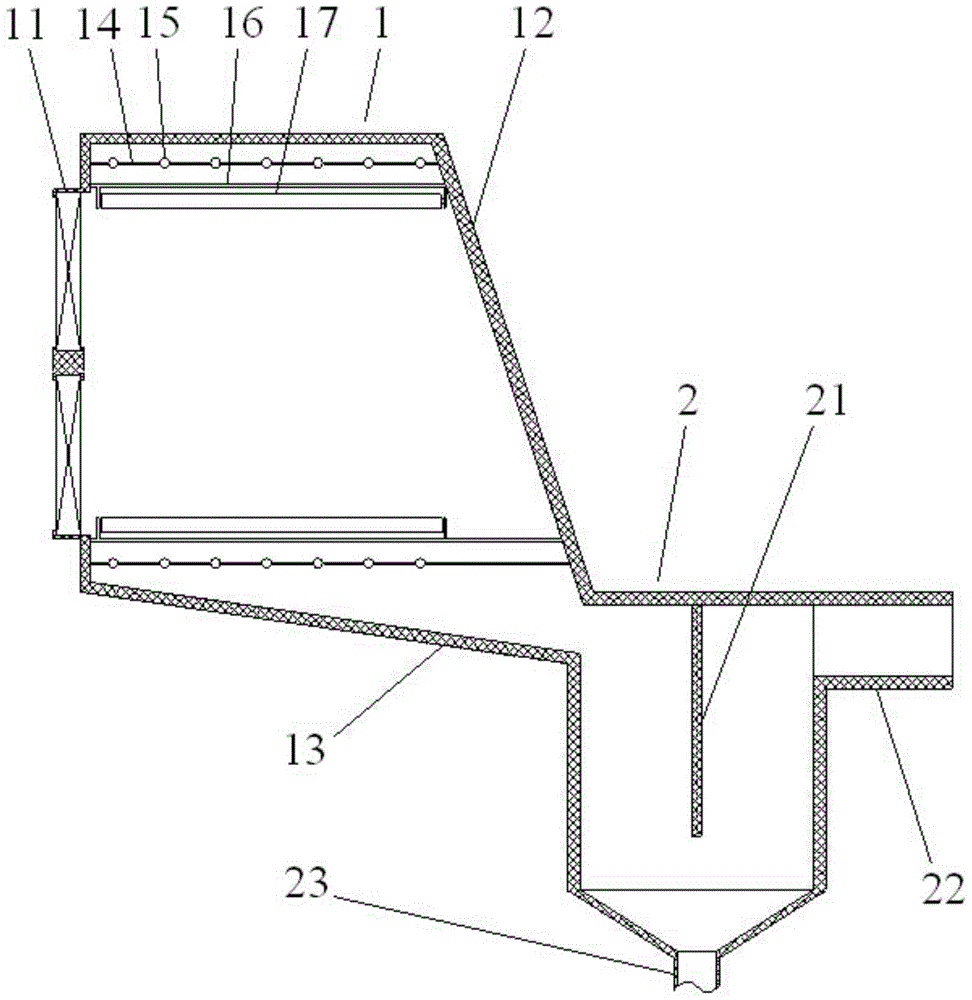

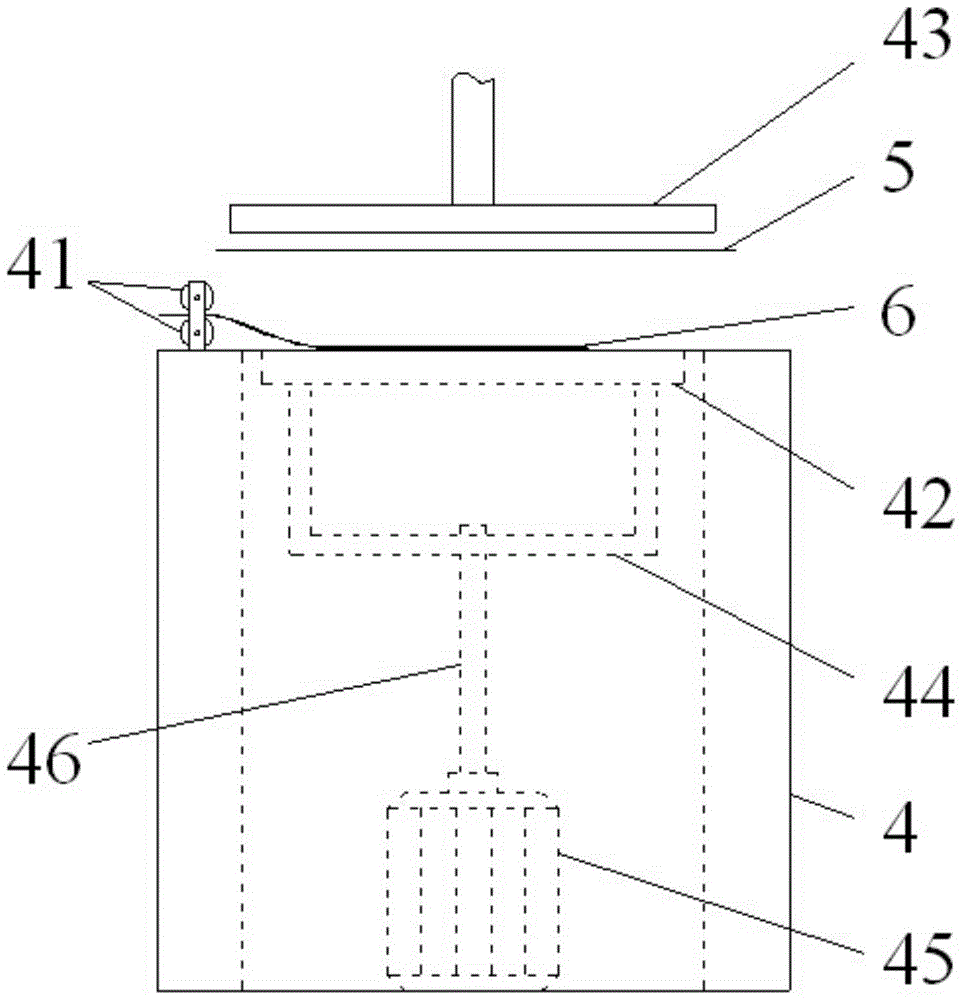

[0019] Such as figure 1 , figure 2 and image 3 As shown, the fast drying film sticking device includes a drying box 1, a waste discharge box 2 and a film sticking machine 4; the drying box 1 and the waste discharge box 2 are integrally connected; The side of the drying box 1 connected to the waste box 2 is set as a condensation plate 12; the bottom surface of the drying box 1 connected to the waste box 2 is set as a deflector 13; The side opposite to the condensing plate 12 is provided with a plurality of fans 11; the top and the bottom of the inside of the drying box 1 are provided with a plurality of guide roller holders 16; the guide roller holder 16 is fixed with a guide Roller 17; a plurality of heating tube fixing brackets 14 are respectively arranged between the guide roller fixing bracket 16 and the top and bottom of the drying cabinet 1; the heating tube fixing bracket 14 is fixed with a heating tube 15; The connection between the waste discharge box 2 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com