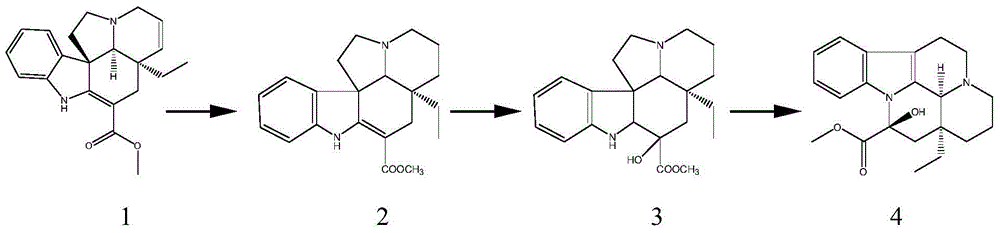

A kind of semi-synthetic method prepares the production technology of vincamine

A production process and vincamine technology, which is applied in the field of chemical synthesis process, can solve the problems of long route, high production equipment requirements and high cost, and achieve the effects of simple process, safe environment and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example provides a kind of preparation method of vincamine, concrete implementation is as follows:

[0027] 1) Weigh 5.0kg of Tabonin hydrochloride and put it into a 100L stainless steel reactor, add 50L of 75% ethanol, stir at room temperature until Tabonin hydrochloride is completely dissolved, then add 250g of Raney nickel into the reactor, and feed hydrogen , Stir after 0.5h, and control the hydrogen pressure at 1.1atm, and react at room temperature for 8h. After the reaction was completed, nitrogen gas was introduced for 10 minutes, the catalyst Raney nickel was removed by filtration, and the crude product of vinfermin was concentrated to obtain the crude product, which was then crystallized with ethyl acetate-ethanol to obtain 4.8 kg of vinfermin hydrochloride with a purity greater than 99.0%.

[0028] 2) Put the vinformin hydrochloride prepared in step 1) into a 100L stainless steel reaction kettle, add 60L of acetic acid aqueous solution with pH=4.5, stir a...

Embodiment 2

[0031] This example provides a kind of preparation method of vincamine, concrete implementation is as follows:

[0032] 1) Weigh 5.0kg of bonin salt of sulphate and put it into a 100L stainless steel reaction kettle, add 100L of 40% methanol, stir at room temperature until the bonin salt of sulphate is completely dissolved, then add 50g of nickel boride, and pass in hydrogen for 0.5h Stir afterward, and control the hydrogen pressure at 1.1 atm, and react for 12 hours. After the reaction was completed, nitrogen gas was introduced for 10 minutes, the catalyst nickel boride was removed by filtration, concentrated to obtain the crude product of vinbromin, and then crystallized with ethyl acetate-ethanol to obtain 4.0 kg of vinbromin sulfate with a purity greater than 99.0%.

[0033] 2) Put the vinbromin sulfate obtained in step 1) in a 100L stainless steel reaction kettle, add 80L of acetic acid aqueous solution with pH=5, stir and dissolve at room temperature, then fill it with n...

Embodiment 3

[0036] This example provides a kind of preparation method of vincamine, concrete implementation is as follows:

[0037] 1) Weigh 5.0kg of Tabonin hydrochloride and put it into a 100L stainless steel reaction kettle, add 80L of 95% ethanol, stir at room temperature until Tabonin hydrochloride is completely dissolved, then add 500g of PdCO 3, feed hydrogen, stir after 0.5h, and control the hydrogen pressure 1.1atm, react for 8h, after the reaction is completed, feed nitrogen for 10min, filter to remove the catalyst PdCO 3 , concentrated to obtain the crude product of Changchun Fermin, and then crystallized with ethyl acetate-ethanol to obtain 4.6kg of Vinchun Fermin hydrochloride with a purity greater than 99.0%;

[0038] 2) Put the vinbromin hydrochloride obtained in step 1) in a 100L stainless steel reaction kettle, add 50L of acetic acid aqueous solution with pH=4, stir and dissolve at room temperature, then fill with nitrogen protection, and react at room temperature for abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com