Asphalt mixing station fuel oil consumption rate display system and control method thereof

A fuel consumption rate and display system technology, applied in measuring devices, instruments, roads, etc., can solve the problems of not being able to complete the fuel consumption rate test in real time, and inconvenient to understand the fuel digestion situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

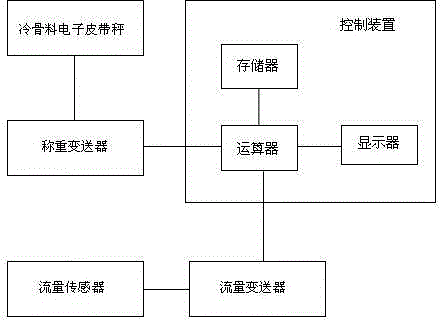

[0027] Embodiment 1: When the fuel consumption rate display system of the asphalt mixing plant is used to display the instantaneous fuel consumption rate, the control method includes the following specific steps.

[0028] Step 1: Start the asphalt mixing plant.

[0029] Step 2: The cold aggregate electronic belt scale collects the cold aggregate flow data at the feed end of the drying drum.

[0030] Step 3: The weighing transmitter reads the aggregate flow data collected by the cold aggregate electronic belt scale and digitizes it, and sends the digitized aggregate weight data information to the control device.

[0031] Step 4: The flow sensor collects the fuel flow data at the fuel injector of the burner.

[0032] Step 5: The flow transmitter reads and quantifies the fuel flow data collected by the flow sensor, and sends the quantified fuel flow information to the memory of the control device for storage.

[0033] Step 6: The calculator in the control device will receive fu...

Embodiment 2

[0035] Embodiment 2: When the fuel consumption rate display system of this asphalt mixing plant is used to display the average fuel consumption rate, the control method includes the following specific steps:

[0036] Step a: Start the asphalt mixing plant.

[0037] Step b: The cold aggregate electronic belt scale collects the flow data of the cold aggregate at the feed end of the drying drum.

[0038] Step c: The weighing transmitter reads the aggregate flow data collected by the cold aggregate electronic belt scale and digitizes it, and sends the digitized aggregate weight data to the memory of the control device for storage.

[0039] Step d: The flow sensor collects fuel flow data at the fuel injector of the burner.

[0040] Step e: The flow transmitter reads and quantifies the fuel flow data collected by the flow sensor, and sends the quantified fuel flow information to a memory for storage.

[0041] Step f: The arithmetic unit in the control device accumulates the receiv...

Embodiment 3

[0043] Embodiment 3: When the fuel consumption rate display system of this asphalt mixing plant is used to display the accumulated fuel consumption, the control method includes the following specific steps:

[0044] Step I: Start the asphalt mixing plant.

[0045] Step II: The flow sensor collects the fuel flow data at the fuel injector of the burner.

[0046] Step III: The flow transmitter reads and quantifies the fuel flow data collected by the flow sensor, and sends the quantified fuel flow information to the memory for storage.

[0047] Step IV: The arithmetic unit receives the quantized fuel flow data, judges and accumulates them, obtains the accumulated fuel consumption, and sends it to the memory for storage.

[0048] Step V: The display of the control device sends an instruction to display the accumulated fuel consumption, and the calculator sends the accumulated fuel consumption to the display for display.

[0049] In the above-mentioned embodiment, the described co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com