Form bag concrete construction support and construction method

A technology of mold bag concrete and construction method, which is applied in earthwork drilling, foundation structure engineering, wellbore lining, etc., can solve problems such as construction difficulties, and achieve the effects of great promotion value, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

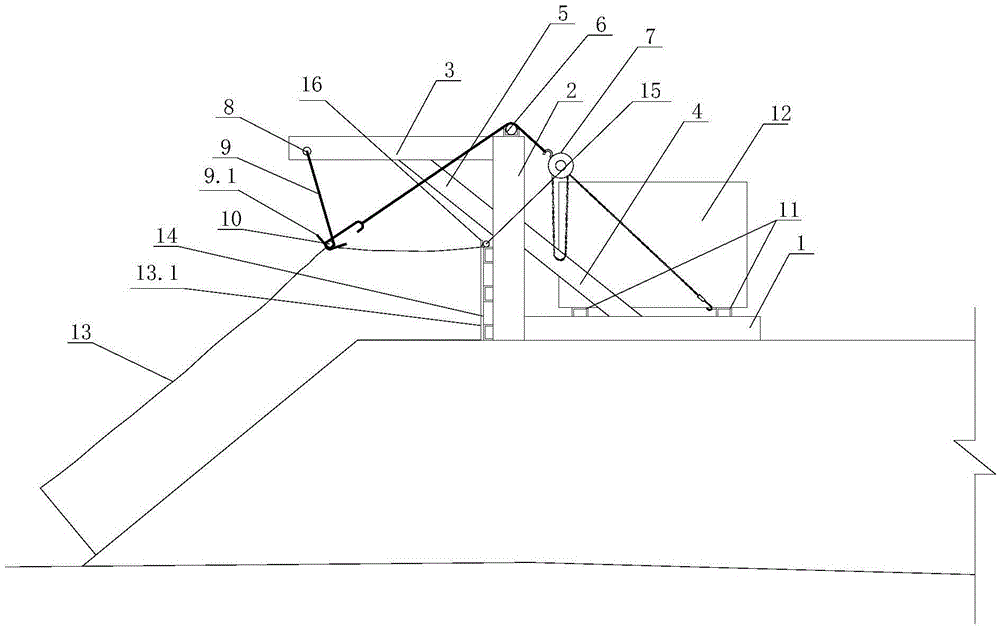

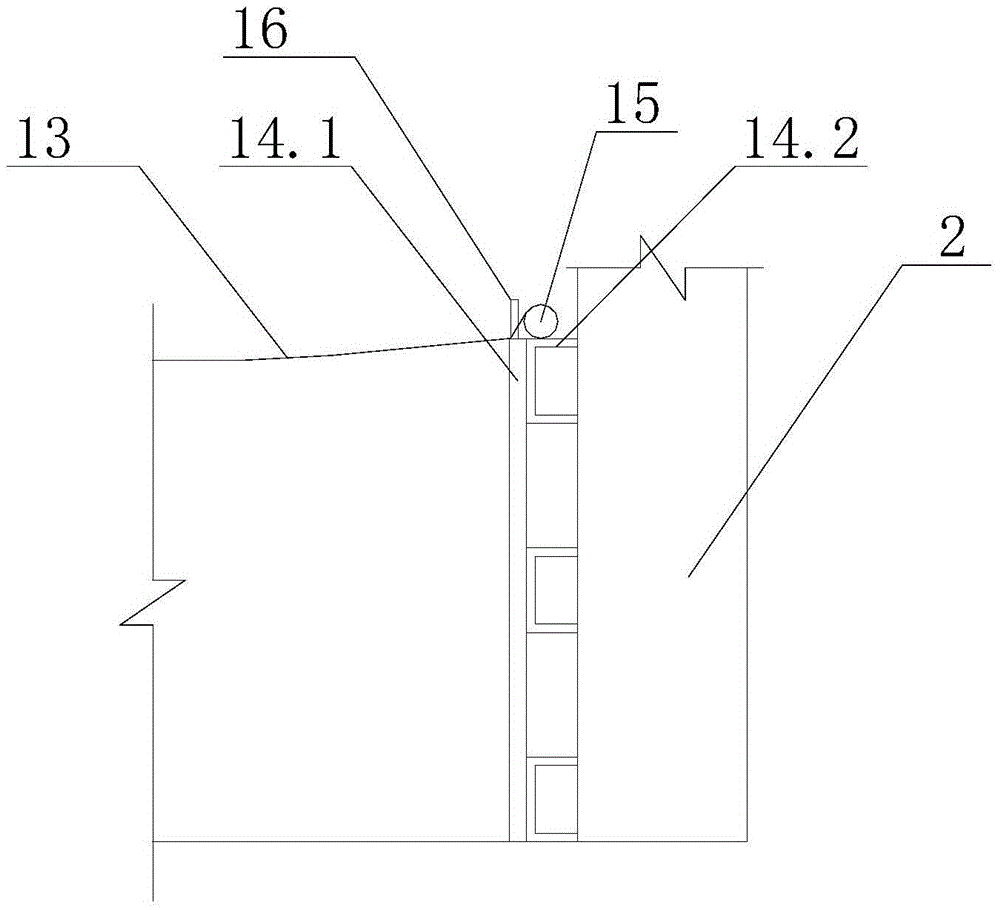

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0023] Such as figure 1 The molded concrete construction bracket shown includes several Z-shaped brackets arranged side by side at equal distances. An upper diagonal brace 5 for reinforcement is connected between them, and a lower diagonal brace 4 for reinforcement is connected between the lower cross bar 1 and the vertical bar 2 . The upper surfaces of all the lower crossbars 1 are connected to the longitudinally extending longitudinal connecting rods 11, and the longitudinal connecting rods 11 are two, and are arranged in parallel on the lower crossbars 1, and the sides of all the vertical bars 2 are connected on the upper crossbars. On the vertically extending baffle plate 14 below the bar 3, namely the longitudinal connecting rod 11 and the baffle plate 14 connect these several Z-shaped supports into a whole, and simultaneously, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com