Post-subsidence pouring belt advancing waterstop impermeable concrete structure and construction technology thereof

A technology of impermeable concrete and construction technology, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc. It can solve the problems of high precipitation cost and long precipitation time, so as to reduce construction difficulty, save groundwater resources, and ensure The effect of the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

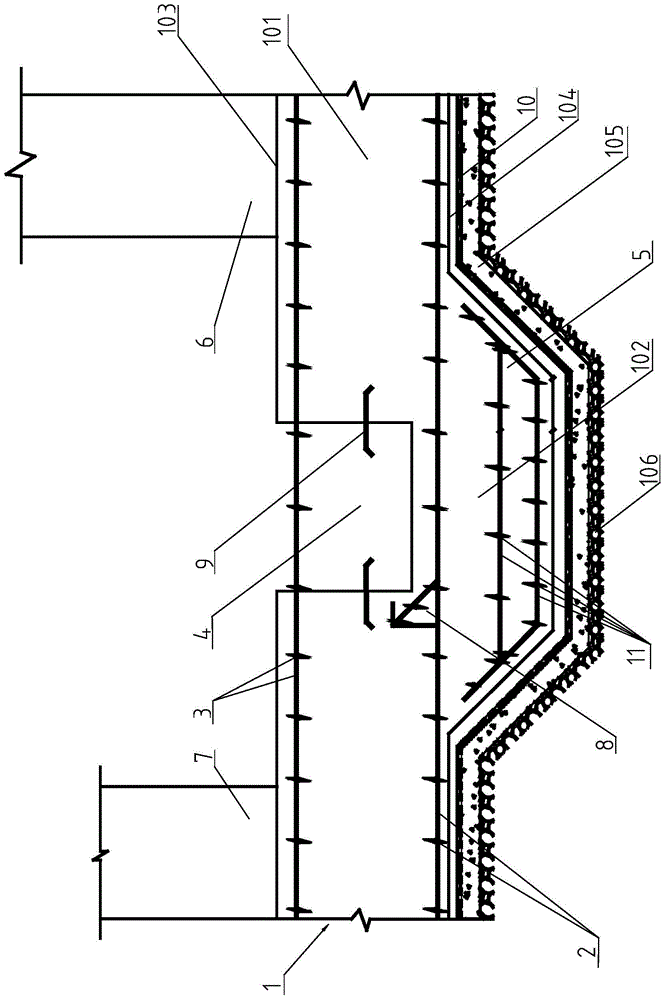

[0028] The post-settlement poured belt advanced water-stop and anti-seepage concrete structure provided by the present invention, such as figure 1 As shown, it includes a force-bearing layer 106, a concrete cushion 105 arranged above the force-bearing layer 106, a raft 1 arranged on the foundation pit, and an inverted trapezoidal reinforced area stress reinforcement 11 is arranged inside the raft 1 The post-settlement pouring zone 4 and the inverted trapezoidal strengthening area 5 below the post-settlement pouring belt 4, and the concrete strengthening pouring area 102 is located below the raft 1 and above the inverted trapezoidal strengthening area 5. The inside of the raft 1 is the raft concrete pouring area 101, and the outer side of the raft concrete pouring area 101 is respectively provided with the lower stress reinforcement I2 of the raft 1 and the upper stress reinforcement II3 of the raft 1, above the stress reinforcement II3 It is the concrete surface I103, and the ...

example 2

[0042] The construction technique of the water-stop and anti-seepage concrete structure with advanced water-stop and seepage-proof concrete structure cast after settlement of the present invention comprises the following steps,

[0043] ① After the settlement of the raft 1, the bottom of the pouring belt 4 is dug downward to a depth H, and then a layer of plain concrete cushion, a layer of SBS coiled material, a layer of concrete protection layer and a layer of SBS coiled material are laid sequentially from bottom to top. The lower part of the trapezoidal reinforced area 5 forms a zigzag-shaped long waterproof layer 10 .

[0044] ② Bundle the structural reinforcement of the poured belt 4 after the trough settlement is formed.

[0045] ③ Binding inverted trapezoidal concrete to strengthen the steel bars in the pouring area 102 .

[0046] ④ Bundle the anti-crack reinforcement structural steel bar 8 in the low-rise area of the poured belt 4 after the trough settlement.

[0047]...

example 3

[0052] The construction technique of the water-stop and anti-seepage concrete structure with advanced water-stop and seepage-proof concrete structure cast after settlement of the present invention comprises the following steps,

[0053] ① After the settlement of the raft 1, the bottom of the pouring belt 4 is dug downward to a depth H, and then a layer of plain concrete cushion, a layer of SBS coiled material, a layer of concrete protective layer and a layer of SBS coiled material are laid sequentially from bottom to top. The lower part of the trapezoidal reinforced area 5 forms a zigzag-shaped long waterproof layer 10 .

[0054] ② Bundle the structural reinforcement of the poured belt 4 after the trough settlement is formed.

[0055] ③ Binding inverted trapezoidal concrete to strengthen the steel bars in the pouring area 102 .

[0056] ④ Bundle the anti-crack reinforcement structural steel bar 8 in the low-rise area of the poured belt 4 after the trough settlement.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com